Littelfuse, Inc., a diversified, industrial technology manufacturing company empowering a sustainable, connected, and safer world, has published its “Littelfuse Solid-State Industrial Relays Quality Test Report”. This paper addresses the risks of choosing a low-quality solid-state relay (SSR) and shares the test results of the Littelfuse products compared to three other suppliers.

Solid-state relays are a critical component in modern electrical and electronic systems providing reliable switching capabilities for various applications. But low-cost SSRs are often made by low-quality manufacturers who do not follow the strict standards and requirements needed for commercial applications. This can lead to mechanical failures under constant and prolonged use.

“When it comes to choosing the right solid-state relay for your application, it’s important to know the quality of the product you are purchasing so that it can withstand the demands of industrial and commercial settings,” said Hugo Neri, Relays Product Manager at Littelfuse. “By choosing a quality solid-state relay, it minimizes serious risks such as fire hazards, electrical shock and injury as well as costly disruptions caused by unreliability and poor performance.”

Risk of Using Low Quality SSR

Solid-State Relays (SSRs) are essential components in modern electrical and electronic systems, offering reliable switching capabilities for diverse applications, ranging from industrial automation to consumer electronics. When selecting the appropriate solid-state relay for your specific needs, it’s crucial to prioritize the quality of the product you’re purchasing.

While there are numerous low-cost SSRs available on the market, choosing based solely on cost can lead to costly mistakes. Low-cost SSRs are often manufactured by companies that lack adherence to strict standards and requirements. These manufacturers may not undergo rigorous testing and certification processes, resulting in the presence of counterfeit SSRs that claim to have the same specifications and performance as reputable brands.

In this report, we delve into the risks associated with choosing low-quality SSRs and present the test results of Littelfuse products compared to two other suppliers.

One of the primary risks of opting for low-quality SSRs is their poor reliability and performance. These relays may exhibit inaccurate and inconsistent switching characteristics, such as inaccurate zero-crossing or random turn-on. These issues can significantly impact the load operation and efficiency. For instance, some low-quality SSRs may fail to switch on or off at the zero-cross point of the alternating current (ac) waveform, leading to transient voltages, currents, harmonic distortion, and electromagnetic interference.

Furthermore, low-quality SSRs often have a shorter lifespan and may fail prematurely, resulting in downtime, maintenance costs, and the need for replacements. This can negatively affect your reputation and credibility as an Original Equipment Manufacturer (OEM) or panel builder who provides quality products and services to your customers and end-users. If you incorporate low-quality SSRs into your machines, panels, or systems, you may face the risk of customer returns, complaints, lawsuits, or loss of trust if the SSRs fail or cause issues. These consequences can have a detrimental impact on your business and profitability in the long run.

Low-cost SSRs might have concealed lower ratings, inferior components, poor design, and inadequate testing and certification. Consequently, they pose significant risks and issues for you and your equipment, including:

- Overheating and fire hazard: Low-quality SSRs frequently employ lower-rated power components internally to switch the load current. This practice leads to excessive heat dissipation and voltage drop, potentially causing overheating, melting, and even fire in the SSR and the connected load.

- Electric shock and injury: Low-quality SSRs not only endanger your safety and equipment but also jeopardize the safety and satisfaction of your customers and end-users. They may lack proper insulation and isolation between the input and output terminals, exposing systems and people to high voltages and currents. This can result in electric shock, injuries, or fatalities if the SSRs malfunction, cause a fire or electric shock, or damage the SSR and the load, generating sparks and arcs that can ignite flammable materials.

- Inadequate protection against overvoltage, overcurrent, short circuit, and surge: Low-quality SSRs may lack sufficient protection against these hazards, which can damage the SSR and the load. Additionally, they may generate sparks and arcs that can ignite flammable materials.

How to Choose a Quality SSR

You might assume that using a well-known brand guarantees high-quality SSRs, but this isn’t always the case. Solid-state technology is highly precise, and not everyone can produce it. Many brands simply private label from low-cost manufacturers to provide comprehensive panel solutions without prioritizing high-quality components.

Here are four general recommendations for finding high-quality SSRs:

1. Compare Pricing and Source: The quickest and easiest way to identify low-quality SSRs and select quality ones is to compare their prices and sources. Low-quality SSRs may offer significantly lower prices, which could seem too good to be true. However, these low prices come at the expense of quality and safety. Always purchase from authorized and reputable sellers, distributors, or websites that can provide you with genuine SSRs backed by warranties, support, and after-sales service.

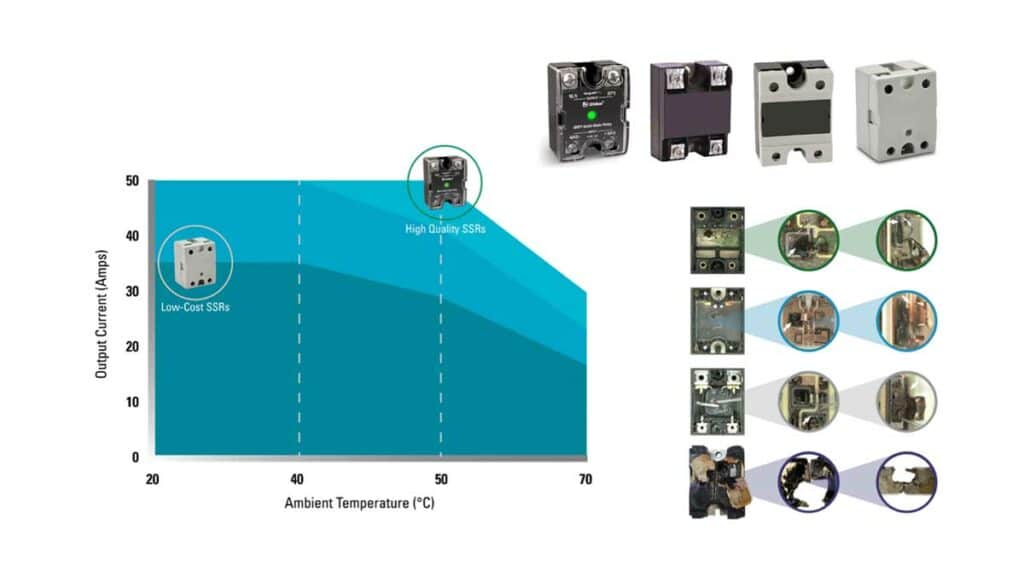

2. Analyze Derating Curves: Thoroughly analyze the datasheet, not only the general values that align with your application, but also the “derating curves.” These curves provide information about the continuous current and ambient temperature at which the product can be used. While there’s an unwritten standard specifying values at 40°C with resistive loads, not all companies adhere to this standard. Additionally, remember to consider a value margin, as even reputable brands may use the product’s limit values in their curves instead of the recommended international safety organization values.

3. Check Standards Conformity and Certifications: Another way to ensure the quality of SSRs is to look for safety marks and certifications indicating that they have undergone testing and certification under the guidelines of independent and reputable organizations.

organizations like IEC (International Electrotechnical Commission). These marks and certifications show that the SSRs comply with the relevant safety, quality, and performance standards and requirements. Some of the common safety marks and certifications for SSRs are:

Official certificates issued by official Third-Party Certified Bodies:

UL or ЯU Mark: This is a North American Safety marks issued by UL, TÜV, or VDE indicate that SSRs have undergone testing and certification to meet applicable standards. The UL Mark, recognized by AHJs and inspectors across the US and Canada, ensures compliance with UL 508 and CSA C22.2. TÜV or VDE Marks, issued by these German safety authorities, demonstrate compliance with European harmonized standards like EN 62314, EN 60947-1, and EN 60947-4-3. While voluntary, these marks are widely accepted and trusted in Germany and other European countries.

Self-declaration certificates from each SSR manufacturer also provide additional assurance. The CE Mark, a European conformity mark, signifies that SSRs meet the essential requirements of relevant EU directives, such as the Low Voltage Directive (LVD) and the Electromagnetic Compatibility Directive (EMC). While mandatory for SSRs sold in the EU, the CE Mark is self-declared by the manufacturer or importer and does not necessitate independent testing or certification.

The UKCA Mark, another UK conformity mark, indicates compliance with UK regulations like the Electrical Equipment (Safety) Regulations 2016 and the Electromagnetic Compatibility Regulations 2016. Similar to the CE Mark, the UKCA Mark is self-declared and does not require independent testing or certification.

4. Proof of Product Testing: Another way to avoid low-quality SSRs and select quality ones is to seek evidence of endurance testing and other quality assurance tests conducted by the manufacturer. These tests demonstrate that the SSRs have been subjected to various stress and environmental conditions, including extreme temperatures, humidity, vibration, shock, and load cycles. These tests validate the SSRs’ performance and durability. Additionally, these tests reveal that the SSRs have been meticulously designed and manufactured using high-quality materials and components, such as SCRs, triacs, MOSFETs, optocouplers, resistors, capacitors, and diodes, which can withstand the electrical and thermal stresses.

Conclusion

This study emphasizes the significance of quality in SSR assembly to minimize risks and enhance reliability. Although all 50A-rated units may share similar catalog specifications, the assembly and design quality varies substantially. The Littelfuse SRP1 series outperformed competitors by two to three times in cycle count, demonstrating our expertise in SSR design and manufacturing.

Littelfuse’s vertical integration, encompassing in-house chip design and wafer fabrication, provides unparalleled control over the supply chain and product quality. Our solid-state technology expertise, rigorous testing, and certification processes ensure that Littelfuse SSRs deliver exceptional performance and safety under various conditions.

For Original Equipment Manufacturers (OEMs) seeking reliability, efficiency, and superior performance in their SSRs, Littelfuse stands out as the unequivocal choice. Adopting Littelfuse SSRs can lead to substantial cost savings over time due to reduced downtime and maintenance. By partnering with Littelfuse, you gain access to decades of innovation and excellence, empowering your applications with unwavering confidence and precision.

Read the complete technical paper here: Littelfuse Solid-State Industrial Relays Quality Test Report