This paper Novel Safe-Life Concept For Circuit Protection Devices was presented by Bruno Zemp, SCHURTER AG , Switzerland during the 5th Space Passive Component Days (SPCD), an International Symposium held from October 15th to 18th, 2024, at ESA/ESTEC in Noordwijk, the Netherlands. Published under permission from ESA SPCD organizers.

Introduction

SCHURTER AG has introduced a groundbreaking redundancy concept known as the “Safe-Life” concept, aimed at enhancing circuit protection devices for high-reliability applications, particularly in the commercial space industry.

With the increasing adoption of commercial off-the-shelf (COTS) components due to cost and lead-time advantages, reliability concerns have surfaced.

The Safe-Life concept is designed to address the limitations of traditional redundancy systems, such as high power dissipation and lack of efficient fault isolation, by utilizing an irreversible microswitch based on MEMS technology.

Key Points

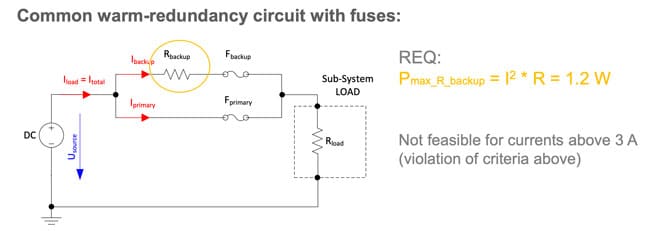

- Problem and Motivation: Traditional redundancy systems suffer from high power dissipation and inadequate fault isolation.

- Safe-Life Concept: Introduces an irreversible microswitch to replace current-limiting resistors, reducing ohmic losses and enhancing fault isolation.

- Design: A three-terminal module incorporating MEMS technology for compact, efficient circuit protection.

- Performance Characterization: Focus on minimizing ohmic losses, ensuring galvanic isolation, and achieving compact device size.

- Results: Promising outcomes with areas identified for further improvement.

Extended Summary

The commercial space industry’s reliance on COTS components presents unique challenges, particularly concerning reliability. Traditional redundancy systems employ parallel arrangements of fuses with current-limiting resistors to manage load currents effectively. However, these systems experience significant power losses when the backup fuse takes over due to the resistor’s inherent high-power dissipation. This leads to thermal management issues in spacecraft designs.

SCHURTER’s Safe-Life concept revolutionizes this approach by substituting the current-limiting resistor with an irreversible microswitch. This innovation not only minimizes power dissipation but also ensures quick and safe isolation of fault circuits. The core of this technology is a MEMS-based microswitch integrated into a highly miniaturized, three-terminal device, designed to carry currents up to 10 A while maintaining low electrical contact resistance under 10 mΩ.

The design includes two key switching contacts: a normally closed contact (NCC) for the primary circuit and a normally open contact (NOC) for the backup circuit. An electromagnetic actuator triggers the switch in the event of a primary circuit failure, ensuring seamless transition and galvanic isolation between circuits. The microswitch system, entirely implemented on a silicon chip, features an intricate assembly involving conductive silver epoxy, ferromagnetic materials, and wire bonds for optimal electrical connectivity.

Performance characterization focused on four objectives: minimizing ohmic losses, ensuring compatibility with components up to 15 A, achieving galvanic isolation, and maintaining a compact size. Cold resistance measurements showed promising low resistance levels, and current step tests demonstrated stable performance up to 10 A. However, devices failed at currents exceeding 13.5 A, primarily due to bond wire meltdown, indicating areas for design improvement. The total power dissipation exceeded the target, highlighting the need for further optimization.

Conclusion

The Safe-Life concept marks a significant advancement in circuit protection for high-reliability applications. While initial results demonstrate the potential for compact, efficient, and reliable performance, certain limitations such as high power dissipation at higher currents and mechanical robustness require further development.

Future work will focus on reducing electrical resistance, enhancing the durability of wire bonds, improving shock/vibration resistance, and simplifying the design to reduce manufacturing costs. This innovative approach holds promise for addressing the evolving needs of space and other high-reliability industries.

Read the full paper: