This paper presents Benefits of Using High-Reliability Polymer Tantalum Capacitors. James Turner, Ph.D. KEMET YAGEO Group, presented this during the 5th Space Passive Component Days (SPCD), an International Symposium held from October 15th to 18th, 2024, at ESA/ESTEC in Noordwijk, the Netherlands. Published under permission from ESA SPCD organizers.

High-reliability polymer tantalum capacitors, particularly KEMET’s T580/T581 series, offer superior performance and reliability compared to manganese dioxide (MnO2) counterparts. Manufacturing these capacitors involves careful material selection, conservative anode designs, and rigorous screening processes, including KEMET’s patented Simulated Breakdown Voltage Screening. This screening identifies and removes weaker parts, resulting in a batch of capacitors with breakdown voltages exceeding 2x rated voltage.

Key Points

- High-Reliability Capacitors: Polymer tantalum capacitors offer superior performance, including lower ESR, enhanced thermal stability, and higher ripple current capabilities, making them ideal for mission-critical applications.

- Manufacturing Insights: Creating high-reliability capacitors requires a design-first approach, emphasizing robustness and quality from the outset, complemented by advanced screening methods like KEMET’s patented SBDS.

- KEMET’s T580/T581 Series: Qualified to the new MIL-PRF-32700 standard, these capacitors incorporate advancements from KEMET’s 25 years of polymer tantalum capacitor manufacturing.

- High-Reliability Capacitor Design: Material selection, production processes, and testing/screening are modified to improve the reliability of capacitors.

- Reliability Comparison: Polymer tantalum capacitors are more reliable than MnO2 capacitors due to the less stressful polymerization process compared to the high-temperature pyrolytic process used in MnO2 capacitors.

- MIL-PRF-32700 Qualification: MIL-PRF-32700 qualified capacitors use conservative anode designs and material sets to enhance reliability.

- Reliability Comparison: Tantalum MnO2 capacitors have a lower failure rate than polymer tantalum capacitors at the same voltage.

- Failure Rate at Different Voltages: The failure rate of polymer tantalum capacitors increases with voltage, while the failure rate of MnO2 capacitors remains relatively stable.

- Test Methodology: Capacitors were subjected to voltage pulses of increasing magnitude to measure their reliability.

- Capacitor Design: Utilizes epoxy casing, stainless-steel lead frames, conservative anode designs, and trusted powder sources for long-term reliability.

- Breakdown Voltage Screening: Employs a patented technology called Simulated Breakdown Voltage Screening to identify and remove weaker capacitors, resulting in a higher breakdown voltage.

- Reliability Testing: Subjected to rigorous process controls, material selection, and stricter quality checks for parameters like capacitance, leakage current, and ESR.

- High-Reliability Capacitors: Designed for demanding environments with rigorous testing and materials for long-term reliability.

- Commercial-Grade Capacitors: Suitable for less critical applications with less rigorous testing and potentially lower reliability in extreme conditions.

- KEMET’s T580/T581 Series: A reliable polymer tantalum capacitor series with MIL-PRF qualification, suitable for demanding applications.

Introduction

The release of MIL-PRF-32700 for polymer tantalum capacitors marks a milestone in their adoption in military, defense, and aerospace applications. These capacitors set new performance benchmarks, offering lower equivalent series resistance (ESR), enhanced thermal stability, and higher ripple current capabilities compared to manganese dioxide (MnO2) predecessors. These improvements enhance electronic system efficiency, longevity, and reduce the risk of failure in critical applications, making polymer tantalum capacitors a preferred choice for designers and engineers.

We’ll provide manufacturing insights and revisit the processes that make capacitors meet high-reliability standards for mission-critical applications in defense and aerospace. While electrical screening plays a role, a robust, high-quality part requires a different mindset in capacitor design. We’ll also discuss the new reliability assessment method, its differences from Weibull screening, and why KEMET’s patented simulated breakdown screening (SBDS) is standard for parts built according to MIL-PRF-32700.

KEMET’s T580/T581 series is the first to be qualified to the new standard and incorporates advancements from 25 years of manufacturing polymer tantalum capacitors. This qualification demonstrates the series’ ability to meet rigorous standards. KEMET’s high-reliability capacitors meet military demands and enhance its commitment to excellence.

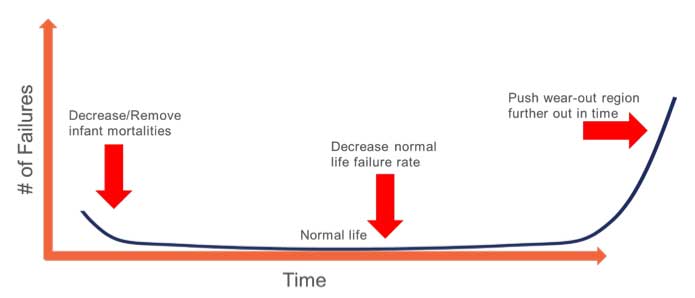

Capacitor design, material selection, production processes, and testing/screening can improve reliability by addressing the “bathtub curve” as shown in Figure 1. These choices reduce early failures, normal failures, and extend the capacitor’s life.

For tantalum capacitors, we focus on material selection (polymer vs. MnO2), conservative anode designs, and screening processes.

Reliability of Polymer Tantalum vs. Tantalum MnO2

MnO2 capacitors have a tantalum anode dipped in manganese nitrate at room temperature, which converts to MnO2 at around 270°C. This process may cause fracturing due to CTE mismatches, creating fault sites that can lead to future failures. Polymer tantalum capacitors use a conductive polymer, poly(3,4-ethylenedioxythiophene) (PEDOT), instead of converting manganese nitrate to manganese dioxide through a high-temperature pyrolytic process. Polymerization reduces stress on the cathode.

The tantalum capacitor has a higher reliability than the MnO2 capacitor since the MnO2 formation process occurs between 25°C and 65°C, which is much lower than the MnO2 counterpart.

To measure the reliability differences, both types of capacitors were subjected to voltage pulses of increasing magnitude from a low impedance source. The thought was that the stress level or voltage across the dielectric triggers the breakdown, and the current pushes the capacitor into failure.

The initial pulse train voltage was set to half the rated value, with a final voltage of four times the rated voltage. Voltage steps were selected based on the start-to-stop range, ensuring a full test sequence within 15 to 40 steps, with increments of 0.1, 0.5, 1, 2.5, or 5 VDC. The power supply delivered high current, maintaining tens of amperes. Each capacitor input was isolated and buffered by a 12,000-uF bank for high charge currents. The pass-fail criterion was a voltage measurement across the capacitor just before discharge. If the voltage was within 95% of the set value, it passed. Failure voltage was recorded, and testing continued until all units failed or the maximum voltage of 4x the rated value was reached. A 5% differential was used to prevent false failures from high-leakage units. [1]

Results showed that the 100-PPM failure rates were around 68% of rated voltage (VR) for the tantalum MnO2 capacitors while it reached 126% and 197% of the higher voltage and lower voltage polymer tantalum capacitors, respectively. The failure rate projection was 9 PPM for MnO2 at 50% VR, 4 PPM for high voltage polymer tantalum at 80% VR, and 2 PPM for low voltage polymer tantalum at 90% VR.

Material Sets and Screening for High-Reliability Polymer Tantalum Capacitors

Tantalum capacitors for military applications utilize advancements in automotive epoxy casings and stainless-steel lead frames to mitigate corrosion damage. Conservative anode designs and trusted powder sources ensure long-term reliability.

KEMET’s T580/T581 series employs patented Simulated Breakdown Voltage Screening to determine a representative breakdown voltage and apply a non-destructive amount to the entire population, identifying hidden dielectric defects. Figure 5 shows a step in the screening process that removes weaker parts, improving the overall breakdown voltage. The remaining capacitors exceed 2x rated voltage, unlike Weibull Graded parts with 1.25x rated voltage. This process avoids wear-out associated with Weibull Grading.

Conclusions

High-reliability tantalum capacitors are manufactured under stringent process controls, including rigorous material control and tighter tolerances for electrical parameters. Stricter quality control ensures the highest performance and durability.

Assurance (QA) processes, including in-line testing and post-manufacturing screening, catch defects before products reach customers. Commercial-grade tantalum capacitors meet consumer or less critical application specifications. They’re reliable in typical conditions but not in extreme environments like high temperatures, mechanical stress, or radiation. They may have wider tolerances and less rigorous testing, reducing reliability in demanding applications.

In some cases, commercial-grade capacitors undergo “up-screening” to remove defective units. Screening can identify potential high-reliability capacitors but can’t change the capacitor’s design or materials. It may identify units meeting short-term reliability but not long-term reliability under harsh conditions. High-reliability capacitors are designed for long operational lives in challenging environments, which up-screening alone can’t fully ensure.

KEMET’s T580/T581 series, now available with the first group of 35V, leverages these improvements. The release of the MIL-PRF and T580/T581 series indicates polymer tantalum capacitors have achieved maturity and adoption in demanding markets. This technology has been used in ground, airborne, and space devices for over a decade.

References

- “Derating Review of Ta-MnO2 vs. Ta-Polymer vs. Al-Polymer vs. NbO-MnO2”, Prymak et.al., 2004 CARTS

- “High Reliability Principles and Verifications in Solid Ta Capacitors”, Freeman et.al., 2014

Read the full paper: