source: PRWeb news

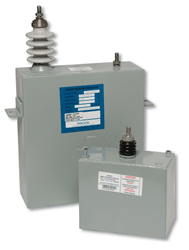

New Bedford, MA (PRWEB)July 27, 2017. Aerovox Corp., a worldwide market leader in film capacitors announces the development of a high voltage capacitor capability in excess of 100,000 volts. High voltage capacitors are used in DC, pulsed power, high frequency AC and specialized applications for defense, industry and medicine.

High voltage capacitors are central to many applications, for instance, groups of large, specially constructed low-inductance, high-voltage capacitors (capacitor banks) supply pulsed power for electromagnetic forming, Marx generators, pulsed lasers, fusion research and particle accelerators. Additionally, these large capacitor banks (reservoirs) are used as energy sources for medical imaging, military and other commercial systems.

The higher voltage ratings and rugged construction of high voltage, snubbers and pulse capacitors make them suitable for applications beyond the capabilities of general purpose units. As well as custom designs, they are available in many configurations to address a wide range of needs.

ITAR compliant Aerovox high voltage capacitors are built in the company’s New Bedford, MA plant using Lean Six Sigma manufacturing practices and undergo rigorous quality assurance testing. They are 100% tested prior to shipment, and test data is retained for five years for complete traceability by individual work order numbers.

“Our capacitance range in high voltage has more than doubled, which is great news for customers looking for performance and durability in critical applications.” said Jim Faughnan, Aerovox President and CEO. “Our high voltage capacitors are manufactured in our advanced New Bedford facility to exacting standards. For customers with specialized needs, the wide voltage range and our flexible manufacturing processes permit custom configurations in high frequency, pulse and snubber capacitors.”