source: Electronics Weekly news

Could graphene be the answer to replacing conflict minerals in the electronics supply chain? writes Richard Wilson, consultant editor Electronics Weekly.

One of the more problematic aspects of electronic component production is its dependence on sourcing ‘conflict minerals’.

These scarce metals such as tin, silver, tungsten and indium are both rare and difficult to extract. But production in small concentrations can be lucrative for African states. An unfortunate, and sadly inevitable, aspect of this is that trade in these minerals has been used to fund armed conflicts, such as in the Democratic Republic of the Congo.

The electronics industry is actively promoting ethical sources of supply for these scarce minerals, most notably through initiatives in the US and Europe. The US responded in 2009 with legislation such as the Congo Conflict Minerals Act, while in Europe a new law will become effective in 2021.

The focus of these legal initiatives is to require companies to provide the traceability necessary to ensure that their supply chains are free from conflict minerals. Many companies decided that the simplest compliance strategy would be to avoid any trade with the DRC. But there may be an alternative which could tackle the issue of conflict minerals head-on.

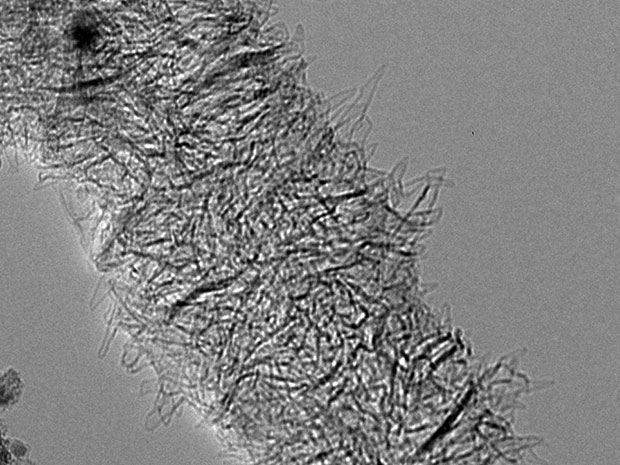

Carbon nanomaterials, such as graphene, could be used to replace many of the metals. Importantly, graphene is a strong material with good conductivity, similar to scarce metals.

A survey by Chalmers University of Technology in Gothenburg, Sweden, has studied the main applications of 14 different metals, and, by reviewing patents and scientific literature, has investigated the potential for replacing them by carbon nanomaterials.

Research into carbon nanomaterials has identified a new range of carbon-based materials with similar properties to metals. And as carbon is such a common and readily available material, there are none of the supply chain manipulation issues associated with the conflict minerals.

According to Rickard Arvidsson and Björn Sandén, researchers in environmental systems analysis at Chalmers University of Technology, 13 of the 14 scarce metals can be replaced by carbon nanomaterials in their most common applications.

The industry’s main focus has been the recycling and reuse of these problematic metals. However, now substitution is a potential alternative that has not been explored to the same extent. Carbon nanomaterials consist solely or mainly of carbon, and are strong materials with good conductivity.

Several scarce metals, found for example, in cables, thin screens, flame-retardants, corrosion protection and capacitors, have similar properties. The researchers say the metals that we are closest to being able to substitute are indium, gallium, beryllium and silver.

This has opened up the possibility of replacing scarce metals with carbon that can be extracted from biomass as part of a natural cycle. Now wouldn’t that be a technical achievement?

featured image source: NEC carbon nano brush