EPCI: I visited this month prof. Josef Sikula from Czech Noise Research Laboratory by Technical University of Brno, Czech Republic. I know Mr. Sikula for many years, back in 90th we were actively speaking at CARTS conferences in USA and Europe about passive components, especially about tantalum capacitors. He was one of the first to introduce concept of MIS structure on tantalum capacitors to explain conductivity mechanisms and behavior at various operating conditions. Today, in his 83, he is still partially working at University, actively travelling and speaking at conferences worldwide. So I was wondering what is his current point of interest and new papers under preparation on passive components that we can expect soon.

1] EPCI: Mr. Professor can you please briefly introduce yourselves and your activities related to passive components?

Prof. Sikula: I spent more than 50years on noise research and use of the noise as the characterization and prediction of reliability of electronic components. At the beginning I was working mainly on enhancement of transistor and active technologies, nevertheless 30 years ago I turned to passive components – resistors and capacitors. The past five years I was occupied mainly by evaluation, characterization and modelling of supercapacitors.

2] EPCI: Supercapacitors are indeed a hot topic. There are continuous releases of higher and higher CV values and new attractive capabilities for automotive EV, space, high power energy storage, industrial etc. Can you please share what was scope of your work and some of your findings with us?

Prof. Sikula: We were recently involved in ESA project for evaluation of supercapacitors for potential space use. Our part of the work was simulation and modelling of supercapacitors based on evaluation of capacitors made by more manufacturers on the market. High fidelity evaluation and modelling with low error is possible only based on deeper understanding of the physical processes inside the structure, so the project itself was a great contributor our overall knowledge about the supercapacitors’ basic mechanisms. Mass volume commercial manufacturers are not interested in basic research of internal processes of their products when their products are passing the customer specification limits. However space, and some industrial applications need to know what is beyond 5000 hours life time or what is expected during overstressing of some parameters, thus deep physical modelling is of key importance here. We completed the modelling on tantalum capacitors, currently working on MLCC structures and finalizing supercapacitors. The MLCC structures are much more complicated with its strong capacitance dependency to DC, AC voltage, temperature etc. but we have succeed electrical modelling with accuracy better than 10% on most of the parts.

3] EPCI: Can we return to the supercapacitors in more details, what type of evaluation and characterization you performed on the tested capacitors?

Prof. Sikula: Apart of basic electrical characterization according to the manufacturer datasheets, we paid main attention to the charge/discharge supercapacitors’ behavior under various load conditions. There are certain features that are not widely known by designers, but it may be important as the design parameter, for example: decrease of capacitance value with number of charge/discharge cycles under different derating and temperature operating conditions.

4] EPCI: I noticed, based on the results that you are just showing me, that we can estimate dielectric absorption value of supercapacitors now that I have not found yet as publicly known parameter, just as a note as “unknown, but highest compare to the other capacitor technologies”.

Prof. Sikula: Yes, the dielectric absorption of supercapacitors can be as high as 30 to 40% … which practically means that the energy from supercapacitors can be released much slowly compare to the other capacitor technologies. For example if you have a 10 F capacitor, the “quick” energy that you have available is closer to 7 F capacitance. The rest 3 F will come slowly with time. This might be the first “disappointing” experience of circuit designers about supercapacitor technology.

5] EPCI: With the current expansion of supercapacitor technology, can you estimate if / when energy densities of this technology will reach or will get more closer to batteries?

Prof. Sikula: I can’t predict it with such strong statement, the battery technologies are moving very rapidly as well as the supercapacitors, so the real siutation is more like “shooting to moving target”. What is clear is that there is still a very strong potential for supercapacitors to increase its Capacitance value and volumetric efficiency. One of about ten charge carriers is currently creating the potential / capacitance value only in accordance to our findings, thus with further optimisation of electrolytes and technologies we can expect continuous increase of capacitance volumetric efficiency of supercapacitors and extended use in wider range of applications.

6] EPCI: Thank you Prof. Sikula for your time and your willingness to share some of your findings with us. When will be possible to read your official results in some form of technical document?

Prof. Sikula: I am presenting results of the ESA project on supercapacitor evaluation study for space use at the next ESA Space Passive Component Days in October 2016 at ESTEC, The Netherlands (http://esaconferencebureau.com/SPCD2016 or link here) where myself or someone from my team will be available to discuss further questions.

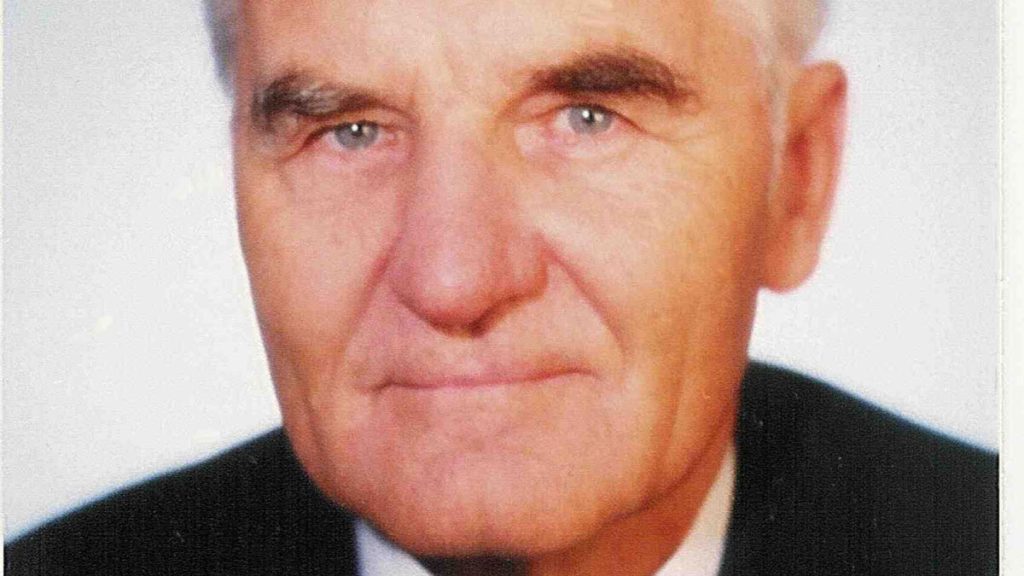

about prof. Ing. RNDr. Josef Šikula, DrSc.

Sikula Josef

Prof. Josef Sikula received his M.Sc. degree in Electronics from the Technical University of Prague in 1957, and his M.Sc. degree in Physics from Komensky University, Bratislava in 1960. He received his Ph.D. degree in Semiconductor Physics in 1965 and DSc in Applied Physics in 1980. He is currently Professor of Applied Physics at Brno University of Technology. In 1970 he founded a group dealing with studies of noise and fluctuation phenomena in solids. His main interests are noise spectroscopy, non-destructive testing, and defect engineering on electronic components mainly resistors and capacitors.