Researchers from Xiangtan University, China published article “Mechanically robust flexible HfO₂-Based antiferroelectric energy storage capacitors via ultra-low-temperature deposition” at Materials Science in Semiconductor Processing journal.

Abstract

Flexible antiferroelectric ceramic capacitors based on Hf0.38Zr0.62O2 thin films were fabricated on MICA substrates via a low-temperature atomic layer deposition (ALD) process (100 °C) combined with e-beam evaporation, addressing the critical demand for mechanically robust energy storage in wearable electronics.

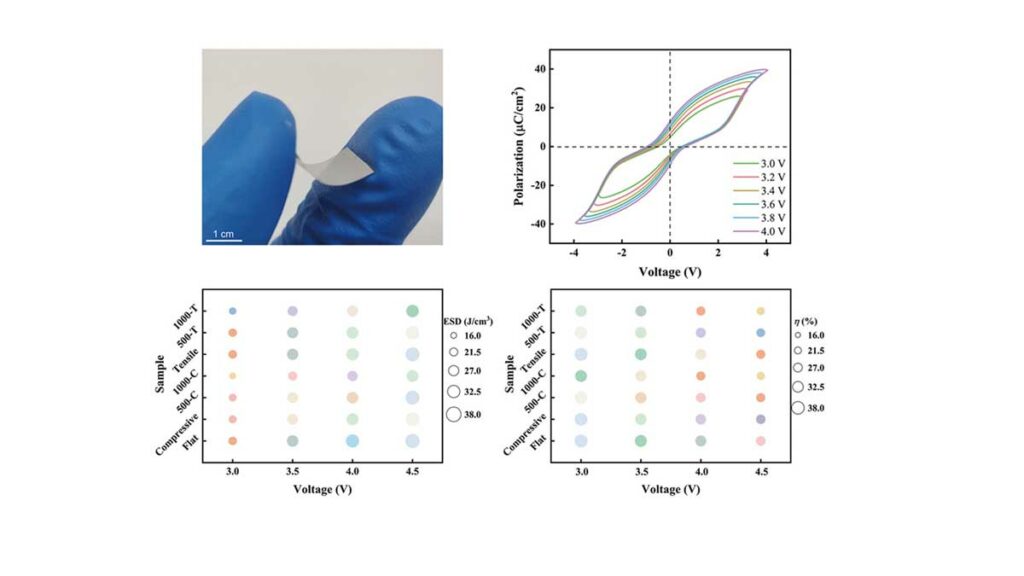

The HZO film with optimized Hf:Zr = 1:2 ratio exhibited a dominant orthorhombic/tetragonal phase mixture, achieving superior antiferroelectricity evidenced by a double hysteresis loop (2Pr = 31.7 μC/cm2 at 4.0 V) and characteristic current peaks.

Remarkably, the devices maintained stable antiferroelectric performance under extreme mechanical bending (radius: 8 mm, 1000 cycles), with minimal degradation in 2Pr (<3 %) and negligible variation in C-V butterfly curves. The capacitors demonstrated high energy storage density (ESD = 38.0 J/cm3) and efficiency (η = 38 %), fatigue endurance exceeding 108 cycles projected 10-year retention (2Pr > 12.33 μC/cm2). This work establishes the synergy of excellent CMOS compatibility, mechanical flexibility, and high reliability of HfO2-based antiferroelectric capacitors for next-generation flexible energy storage systems.

Flexible electronics—spanning wearable health sensors, foldable displays, and implantable devices—are reshaping how we interact with technology. Yet, their advancement is hampered by the lack of energy storage systems that can combine high energy density, mechanical resilience, miniaturization, and safety. Rigid components don’t tolerate repeated bending, while supercapacitors and batteries trade off between power output, energy density, and lifecycle. Moreover, traditional lead-based ferroelectrics, despite their strong polarization properties, suffer from toxicity and brittleness.

This study proposes an alternative: hafnium oxide (HfO₂)-based antiferroelectric (AFE) capacitors fabricated on flexible MICA substrates via an ultra-low-temperature atomic layer deposition (ALD) process at 100 °C. This approach promises high performance, CMOS compatibility, and mechanical robustness—essential for next-generation flexible devices.

Key Points

| Feature | Details |

|---|---|

| Material | Hf₀.₃₈Zr₀.₆₂O₂ (HZO) thin film |

| Process | ALD at 100 °C + e-beam evaporation |

| Substrate | Flexible fluorophlogopite mica |

| Energy Density | 38.0 J/cm³ |

| Efficiency | 38% |

| Polarization (2Pr) | 31.7 μC/cm² at 4.0 V |

| Mechanical Endurance | >97% retention after 1000 bends (radius: 8 mm) |

| Fatigue Endurance | Projected >10⁸ cycles; ~10-year retention |

| CMOS Compatible | Yes, for seamless integration into semiconductor processes |

Extended Summary

The paper opens by mapping the limitations of current flexible energy storage technologies. Supercapacitors deliver rapid charge/discharge rates but lack sufficient energy density, whereas flexible batteries offer more energy storage at the expense of power output and cycling stability. Lead-containing perovskite AFEs are further disadvantaged by toxicity and poor mechanical tolerance.

HfO₂-based AFEs, particularly HfₓZr₁₋ₓO₂ (HZO), are presented as an optimal solution: lead-free, scalable to ultra-thin films, and compatible with established CMOS workflows. The composition ratio Hf:Zr = 1:2 encourages a mixed orthorhombic/tetragonal phase structure. This enhances antiferroelectricity through electric-field-induced phase transitions, which are inherently stable even in sub-10 nm films. The key innovation here is lowering ALD deposition temperature from conventional >250 °C to 100 °C, enabling safe fabrication on thermally sensitive flexible substrates like mica without structural damage.

Mechanically, the capacitors are built without buffer or seed layers, simplifying manufacturing. High-resolution TEM imaging shows highly crystalline, well-aligned lattice structures—evidence of phase stability and film quality. Functionally, the devices display strong double hysteresis loops with symmetric current peaks, reflecting robust AFE behavior.

When subjected to mechanical bending (radius 8 mm, 1000 cycles), the capacitors retained >97% of original polarization with negligible changes in capacitance–voltage butterfly curves. Fatigue testing projects stability beyond 10⁸ electrical cycles and over a decade of operational life. The energy storage density of 38.0 J/cm³ and efficiency of 38% place these capacitors in a competitive performance bracket for flexible systems.

This combination of mechanical toughness, electrical performance, and manufacturability signals a major step forward in practical flexible energy storage design.

Conclusion

The study proves that HfO₂-based antiferroelectric capacitors deposited via ultra-low-temperature ALD can achieve the trifecta of high energy density, mechanical flexibility, and long-term durability—all while being fully CMOS process-compatible. By eliminating the need for buffer layers and enabling integration onto flexible substrates, this method offers a scalable pathway for deploying robust energy storage in wearables, implantable electronics, and other next-gen flexible devices.

Read the full paper:

Qin Jiang, Dan Li, Yingfang Zhu, Hao Li, Yujie Wu, Yang Zhan, Qianrun Li, Shaoan Yan,

Mechanically robust flexible HfO2-Based antiferroelectric energy storage capacitors via ultra-low-temperature deposition,

Materials Science in Semiconductor Processing, Volume 200, 2025, 109912,

ISSN 1369-8001,

https://doi.org/10.1016/j.mssp.2025.109912.

(https://www.sciencedirect.com/science/article/pii/S1369800125006493)