This paper on Development Of Highly Integrated W-Band Circulators/Isolators Based On Substrate Integrated Waveguide (SIW) Technology was presented by Henrik Kettunen, Harp Technologies Ltd, Finland during the 5th Space Passive Component Days (SPCD), an International Symposium held from October 15th to 18th, 2024, at ESA/ESTEC in Noordwijk, the Netherlands. Published under permission from ESA SPCD organizers.

Introduction

The article focuses on the design, manufacturing, and testing of highly integrated W-band circulators and isolators operating within the frequency range of 81–86 GHz.

These devices utilize Substrate Integrated Waveguide (SIW) technology, which offers advantages such as compactness, cost-effectiveness, and ease of integration compared to traditional waveguide technologies. The development aims to address challenges such as bulkiness and high costs associated with standard rectangular waveguides, particularly for space applications.

Key Points

- Objective: To develop W-band circulators and isolators using SIW technology integrated with Low Temperature Co-Fired Ceramic (LTCC) substrates.

- Design: Implementation of Y-junction circulators and isolators with ferrite resonators for non-reciprocal signal routing.

- Challenges: Issues identified with mechanical assembly, material tolerances, and discrepancies between simulated and measured performance.

- Improvements: Introduction of silver epoxy to enhance ferrite contact, leading to better performance.

Extended Summary

The project began by integrating SIW technology within LTCC materials to address integration and cost issues common in high-frequency microwave components. SIW allows rectangular waveguide functionalities to be embedded directly into PCB substrates, making it an attractive option for space-related RF applications. The LTCC process, advantageous for creating three-dimensional structures, was chosen due to its compatibility with SIW designs.

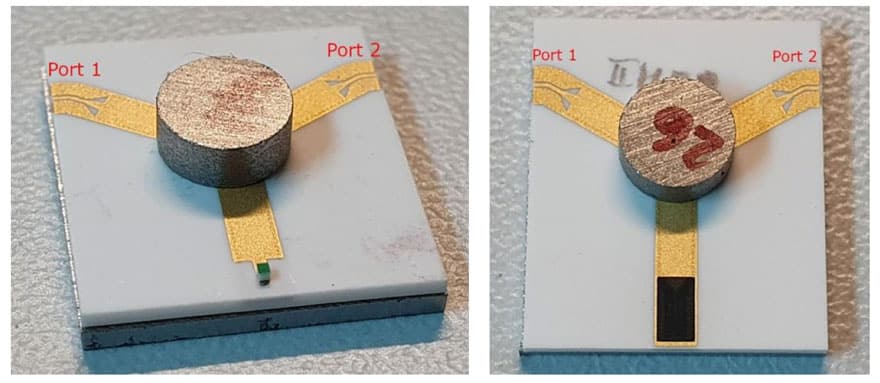

The circulator design was based on a Y-junction structure incorporating a ferrite resonator, biased with a permanent magnet to achieve the desired non-reciprocal properties.

To facilitate measurements, the devices were equipped with Grounded Co-Planar Waveguide (GCPW) interfaces. The isolator variants were derived from the circulator by terminating one port with either a discrete resistor or a distributed absorber, both implemented using LTCC-compatible techniques.

Despite promising simulation results, the fabricated devices exhibited poor performance. Key issues included inadequate signal matching and insufficient non-reciprocity. Troubleshooting revealed that assembly imperfections, particularly in establishing effective galvanic contact between the ferrite and conductive surfaces, were primary contributors to performance degradation. Re-assembly with added silver epoxy significantly improved signal matching and reduced insertion losses, although complete resolution of non-reciprocal behavior issues remained elusive.

Conclusion

While the LTCC-SIW circulators and isolators did not meet performance specifications after two manufacturing iterations, the project provided valuable insights into the challenges of integrating SIW technology at W-band frequencies. The findings highlighted the critical importance of precise mechanical assembly and material tolerances.

Future efforts may benefit from targeting lower frequency bands, where manufacturing tolerances are less stringent, and ferrite performance is more efficient. Despite these challenges, SIW technology remains a promising avenue for developing lightweight, cost-effective components for space applications.

Read the full paper: