Source: Open PR news, Isabellenhütte news

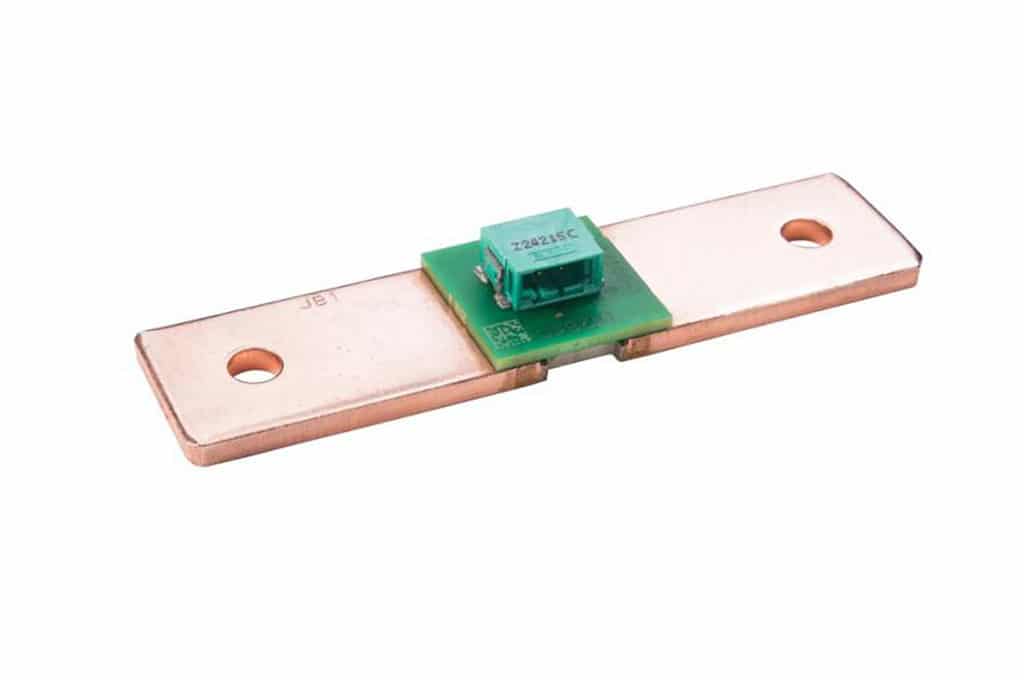

The unique feature of the new BAC shunt from Isabellenhütte is the small circuit board attached to the shunt. The board includes a connector for an easy connection of the measurement connection. Users are ensured a reliable measurement of signals and are spared an additional process step during production.

The concept of this innovative precision resistor allows for a much more flexible and efficient signal transmission than with conventional shunts. The BAC is delivered complete with mini-circuit board with access to the sense terminals via a plug connector for the current measurement. Instead of using complex solutions, such as welded-on terminal pins, flex cables or a connection to the evaluation electronics on the main circuit board, the measuring signal can be tapped directly by the BAC resistor. The connector is used to tap the voltage values in the customer’s higher-level systems.

The resistance values of the BAC are 0.1 mOhm (320 A). Another low-ohmic version is designed for current measurements up to 550 A (0.05 mOhm). This shunt is suitable for power ratings up to 15 W. Other resistance values are also possible.

Leaner production process and more flexible design

In the range of small to medium quantities in particular, the BAC current sensor offers significant cost advantages due to its simplified connection process. It is no longer necessary, for example, to weld on pins. The BAC’s main application is current measurement for electronic battery management systems in forklifts, electric scooters as well as other hybrid and electric vehicles. Other applications include current measurements in welding equipment.

Users have more options when designing their products. Since the measuring signals are not evaluated on the application’s printed circuit board, the BAC shunt does not necessarily have to be placed on the electronics.

High-precision and long-term stable measurement results

Another advantage of the shunt design with circuit board is the high-precision, long-term stable measurement results. MANGANIN® a special alloy designed by Isabellenhütte forms the resistance element of the BAC, which is electron beam welded between two Copper strips. MANGANIN® is characterized by an extremely low temperature dependence. The temperature coefficient (TCR) for the BAC series thus lies in the range 100 ppm/K. By comparison, Copper has a TCR of 4,000 ppm/K. So, if the sense pins are eliminated and the measuring signal can be tapped directly on the underside of the circuit board by the Manganese resistance alloy, then the negative impact of Copper on the temperature coefficient is also largely eliminated.

Customer-specific designs of the standard product

The BAC shunt is a standard passive component, but can be customized for the respective application, for example, the resistance values, the physical size or the selection of plug connectors. In order to avoid transfer resistances due to oxidation, a version with Tin-plated or Nickel-plated Copper connections can also be supplied. Isabellenhütte guarantees a precise measurement and permanent transmission of measuring signals throughout the entire life cycle and therefore also the process reliability of the entire component.