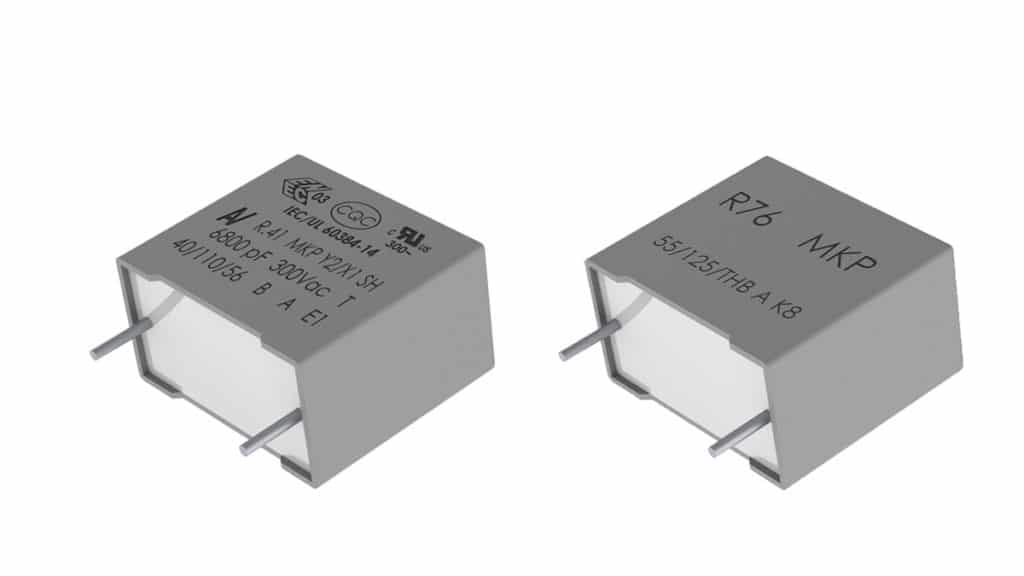

Kemet R41T and R76H new metallized polypropylene film capacitor series offer a high-power density solution for harsh environments and electric vehicle applications.

KEMET Corporation a leading global supplier of electronic components, has launched the R41T and R76H series AEC-Q200 qualified metallized polypropylene film capacitors. This series builds on the company’s long-standing expertise in power management solutions by leveraging advances in manufacturing technology and new materials to address the stringent requirements of the latest automotive applications, including those for electric vehicle (EV) powertrains and Advanced Driver Assistance Systems (ADAS).

This addition to KEMET’s product portfolio has a 125ºC maximum operating temperature and exceeds the requirements of 85ºC/85% relative humidity temperature-bias-humidity tests. The R41T and R76H film capacitors support the design of high-performance, high-reliability circuits including those based on Wide Band Gap (WBG) semiconductor solutions. According to BloombergNEF’s Electric Vehicle Outlook 2019, up to 57% of passenger vehicles are projected to be electric by 2040. These new film capacitors complement the rapid growth in electronic content on a typical passenger vehicle.

“The new technology employed in our R41T and R76H and metallized polypropylene film capacitors ensures a high level of electrical performance along with industry-leading levels of ruggedness and reliability,” said Dr. Philip Lessner, KEMET Senior Vice President and Chief Technology Officer.

“With silicon approaching the limits of its development, the WBG market is expected to grow significantly, reaching a forecasted $1,820 million in 2024 – an increase of 33.4% over a five-year period*. KEMET’s expertise in power management solutions is well aligned with this trend and these film capacitors provide further evidence as well as practical solutions for design engineers in automotive and other sectors.”

* Source: WBG Power Devices market report by Market Study Report, LLC