Dr. Vladimir Azbel, an independent consultant on tantalum capacitors, discusses impact of MnOx parameters to cathode quality of tantalum capacitors in this paper.

Key Takeaways

- The study identifies microhardness (MH) as a key indirect metric for assessing MnOₓ cathode quality.

- Higher drying temperatures and Mn(NO₃)₂ concentrations increase MH, indicating denser, less conductive phases that raise ESR.

- The difference in MH (ΔMH) before and after stripping the MnOₓ layer serves as a diagnostic tool for cathode quality and ESR levels.

- This ΔMH-based approach acts as a benchmark for monitoring the MnOₓ deposition process in various capacitor designs.

The objective of this work was to identify a quantitative parameter that could “digitize” the deposition process and use MH as an indirect metric of MnOₓ cathode quality. The goal is to enhance the yield and reliability of conventional MnO2 tantalum capacitors.

Introduction

In materials science, microhardness (MH) is traditionally used as an indirect indicator of a material’s electrical resistivity because it is sensitive to defect density, porosity, and the degree of crystallinity.

At manufacturing stages where direct electrical measurements are not possible (for example, during pressing and sintering of tantalum capacitor anodes), the material condition can be assessed through its mechanical properties, which reflect its microstructure.

While working with tantalum capacitor anodes, I asked whether this approach could also be applied to the cathode layer formed from manganese oxide (MnOₓ), which directly affects the equivalent series resistance (ESR) of the finished capacitor.

MnOₓ forms through the thermal decomposition of manganese nitrate (Mn(NO₃)2 within the pores of the anodic Ta₂O₅ oxide. Although this reaction appears simple, the actual composition and structure of the resulting oxide strongly depend on the deposition conditions, primarily on the drying temperature and solution concentration.

These parameters determine not only the phase composition of MnOₓ but also its microhardness. The phase composition, in turn, influences the electrical conductivity of the cathode layer and, consequently, the ESR of the capacitor.

Results and Discussion

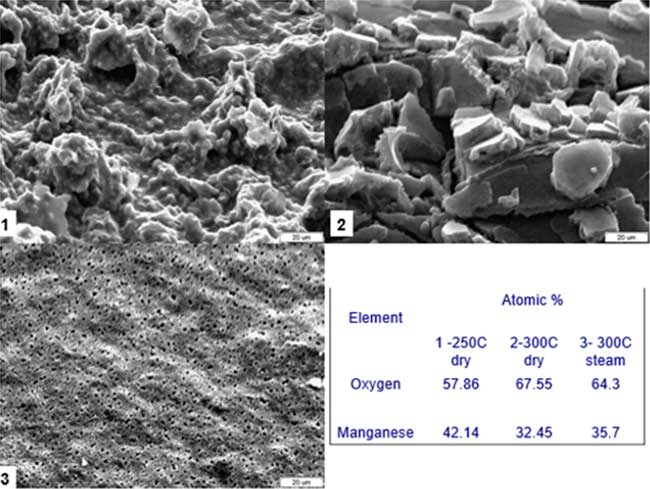

To evaluate the influence of drying temperature and Mn(NO₃)₂ concentration on the properties of the cathode layer, MH measurements were performed on polished cross-sections of identical anodes. All anodes underwent anodization at 200 V, followed by various impregnation and thermal treatment regimes.

The obtained data are summarized in Table 1.

| Sample | Number of dips | Relative Mn concentration | T°C, dry/steam | Average HV (kg/mm²) | Mn oxide contribution |

| Sint (pellet) | – | – | – | 65 | – |

| Sint + 200V | – | – | – | 148 | – |

| Sint + 200V | 5 (no dips) | 0 | 250 | 130 | -18 |

| Sint + 200V | 5 | 1.35 | 250 | 173 | 25 |

| Sint + 200V | 5 | 1.16 | 300 | 166 | 18 |

| Sint + 200V | 5 | 1.55 | 300 | 334 | 186 |

| Sint + 200V | 2 | 1.55 | 300 steam | 185 | 37 |

| Sint + 200V | 7 | 1.55 | 300 steam | 345 | 197 |

| Sint + 200V | 7+1 | 1.55+1.17 | 300 steam+ 400 dry | 298 | 150 |

Cathode Layer Morphology

Interpretation of Results

Increasing both the temperature and Mn(NO₃)₂ concentration leads to higher MH.

The transition from the sintered anode (65 HV) to the anodized one (148 HV) reflects densification due to the formation of the Ta₂O₅ layer.

Further increase in MH after cathode deposition corresponds to the formation of MnOₓ.

Under moderate conditions (250 °C, baseline concentration), MH ≈ 130–170 HV, which corresponds to defective and partially reduced phases such as MnO₂₋δ or γ-MnO₂. These phases exhibit high electrical conductivity, leading to low ESR.

At higher concentrations and temperatures (up to 300 °C), MH increases to > 300 HV, indicating a transition to denser, more crystalline phases such as β-MnO₂ or Mn₂O₃, which are less defective and less conductive, resulting in higher ESR.

Thus, for MnOₓ cathode layers, the following relationship can be established:

Low MH → defective, highly conductive phases → low ESR

High MH → dense, poorly conductive phases → high ESR

Correlation with Known Properties of Manganese Oxides

The electrical conductivity of manganese oxides is strongly linked to the oxidation state of manganese ions (Mnⁿ⁺) and their electronic structure, which affects electron hopping between different valence states (see Table 2).

As the formal oxidation state of manganese increases (from MnO to MnO₂), electrical conductivity tends to improve, while microhardness increases with phase densification and crystallinity.

| Type of oxide | Microhardness, HV (kg/mm²) | Relative Conductivity (see Appendix) | Effect on ESR (trend) |

| MnO | ~400–600 | Very Poor (Insulator) | low, but unstable |

| Mn₃O₄ | ~700–900 | moderate (n-type) | moderate |

| Mn₂O₃ | ~900–1100 | Poor | high |

| MnO₂ | ~1200–1500 | Good | high |

Comparison of Products from Different Manufacturers

To validate this approach, a series of measurements was conducted on three tantalum capacitor designs — 15 µF / 35 V, 22 µF / 35 V, and 10 µF / 50 V — manufactured by KEMET, AVX, Nichicon, and Vishay.

All samples were purchased from the open market and met their nominal specifications, allowing comparison based on anode structure and process quality.

At the first stage, polished cross-sections of the finished capacitors were prepared (Figure 2), and MH measurements were taken, representing the combined contribution of the anode and the cathode layer of manganese oxide.

Next, the capacitors underwent a stripping procedure, after which MH was measured again on the same anodes without the MnOₓ layer.

The difference between these two MH values represents the characteristic microhardness contribution of the MnOₓ layer.

Each value was averaged over 7–10 measurements on representative cross-section regions.

The measured difference in MH (ΔMH) ranged from 70 to 100 kg/mm², depending on capacitor design and manufacturer.

For these samples, ESR values were 25–40% below the upper datasheet limits.

In contrast, for capacitors where ΔMH = 130–150 kg/mm², ESR values were close to or above the upper specification limit.

It can therefore be inferred that a ΔMH of approximately 100 kg/mm² corresponds to the formation of an optimal MnOₓ phase combining adequate electrical conductivity with structural stability under operating conditions.

Conclusions

- Microhardness (MH) is an informative and quantitatively reproducible parameter that reflects the phase composition and defectiveness of manganese oxide (MnOₓ) formed during impregnation of tantalum anodes with Mn(NO₃)₂ solution.

- Increasing Mn concentration and drying temperature leads to higher MH (from 130–170 to > 300 kg/mm²), indicating a transition from defective, conductive MnO₂₋δ phases to dense β-MnO₂ or Mn₂O₃ phases with lower conductivity.

- Higher MH correlates with increased ESR, since harder and more oxidized MnOₓ phases possess reduced electrical conductivity, while lower MH corresponds to more defective, conductive structures yielding lower ESR.

- The difference in MH measured before and after removal (stripping) of the MnOₓ layer serves as a diagnostic parameter — a “mechanical fingerprint” of cathode quality — and an indirect indicator of ESR level and deposition accuracy.

- MH measurement on capacitor cross-sections thus provides a universal, design-independent tool for monitoring the MnOₓ deposition process and for controlling impregnation and drying regimes during the qualification of new tantalum capacitor designs.

- The proposed ΔMH-based approach can also be used as a benchmark reference when similar tantalum capacitor designs are qualified. Once established on a validated (qualified) capacitor type, the measured ΔMH value serves as a reproducible benchmark for assessing cathode quality and ESR behavior in production or during process transfers.