Murata Manufacturing Co Ltd unveils a cutting-edge electronic timing device featuring exceptional accuracy ±40ppm and reliability even in wide-temperature -40°C to +125°C conditions.

By addressing the limitations of current timing components in automotive electronic systems, it enhances the design and deployment of next-generation In-Vehicle Networks (IVN), wireless communication, and Advanced Driver Assistance Systems (ADAS) functions.

As the automotive industry continues to pursue greater integration and electronic downsizing to address the expanding number of critical electronic systems, the performance requirements for components are growing.

In order to achieve tighter packaging without compromising accuracy, it is now necessary for critical components like timing devices to have higher temperature limits. There is also a growing demand to incorporate features like Bluetooth® Low Energy (BLE) and ethernet in vehicles, which demands more accurate timing than what is typically offered by automotive crystal units.

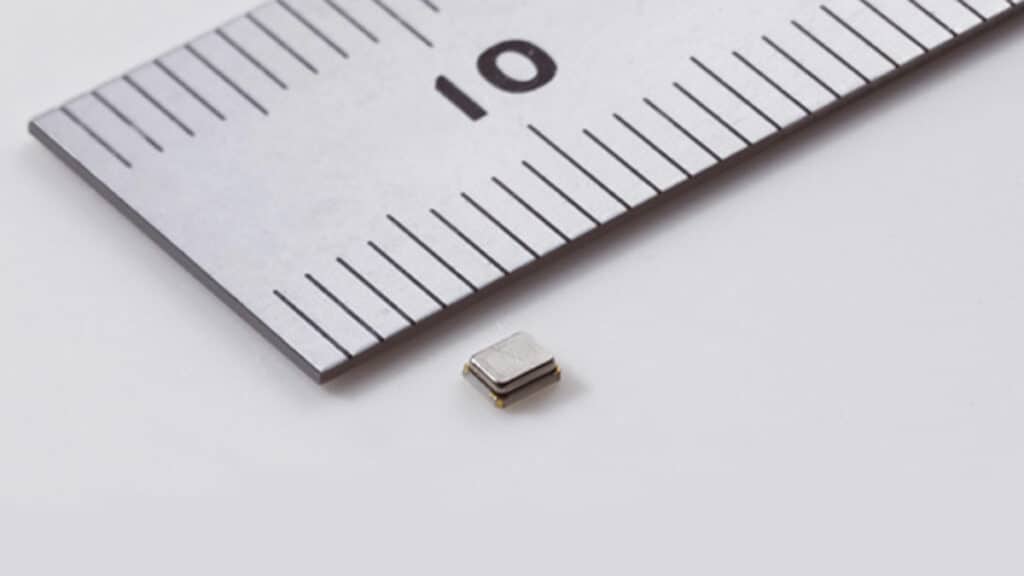

Murata’s high accuracy and high temp automotive crystal (HCR), or XRCGE_M_F series, redefines timing component performance and reliability. It sets a new global standard as the first of its kind to achieve a total frequency tolerance of ±40 ppm throughout an operating temperature range of -40°C to +125°C. This combination allows automotive engineers to achieve the stable and highly accurate timing without the need for system calibration or temperature compensation measures, reducing development efforts and costs.

Murata has a long-standing history of being at the forefront of automotive timing solutions, starting with the introduction of its ceramic resonators in 1997 and followed by its crystal units in 2015 – HCR is the next step. Through the optimization of artificial crystal growth, assembly, and inspection, Murata’s groundbreaking resin-sealed package technology, along with the optimization of crystal design, allows HCR to achieve high-temperature operation and high accuracy. This combination is perfectly suited to support the latest vehicle communication and safety functions such as CAN and ethernet IVNs, ADAS components like cameras, LIDAR, and RADAR, as well as wireless communication technologies such as RF, NFC, BLE, Zigbee™, and UWB.

“HCR is a true step forward that perfectly aligns with the latest automotive demands,” said Munenori Hikita, Director of Functional Devices Division at Murata. “With our ‘world’s first’ solution, engineers will be able to deploy downsized designs and high performance communication circuits without compromise.”

The HCR lineup is underpinned by Murata’s stable and reliable multi-source supply chain, ensuring automotive users have no concerns over supply, while its high temperature operating window and strong resistance to solder cracks guarantee long-term reliability. The components have already entered mass production and samples are available upon request.