source: EIN Presswire news

ROCHESTER, N.Y., USA, August 17, 2017 — Piezoelectric sensors—which measure changes in pressure, acceleration, temperature, strain or force by converting them to an electrical charge*—are utilized in countless applications. From keeping time inside a clock to sensing pressure on the screen of a smartphone, from detecting a car crash for the deployment of an airbag to testing the stability of a bridge, piezoelectric sensors play a critical role in quality assurance and process control.

Piezoelectric sensors must be light as a feather and small in size, and their circuits are very sensitive to noise. That is why developers of these sensors turn to Ohmcraft for its expertise in manufacturing low noise and ultra-high resistance resistors in small form factors.

“Because they are measurement tools, piezoelectric sensors are extremely sensitive,” said Eric Van Wormer, Vice President of the Ohmcraft division of Micropen Technologies. “Our precision resistors play a key role in the operation of the sensors, ensuring that they are as accurate and reliable as possible. Our customers have relied on Ohmcraft to make these high resistance resistors for many years.”

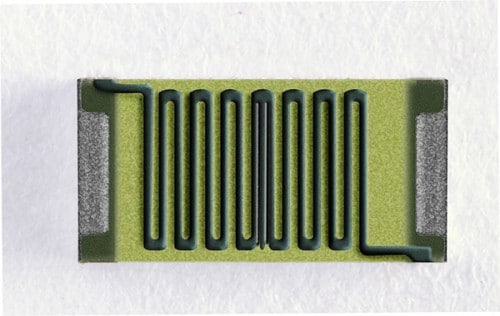

Ohmcraft’s thick-film, surface mount resistors are engineered to meet application specific needs. Its technology utilizes the proprietary Micropen electronic printing system to “print” precise, narrow, serpentine lines with resistive ink on a ceramic substrate, producing higher performance resistors over a wider range of values on a smaller surface area than is possible with conventional film resistor technology.

*Source: https://en.wikipedia.org/wiki/Piezoelectric_sensor