Panasonic Corporation announced that its Industry Company has commercialized the JX series of SP-Cap® conductive polymer aluminum electrolytic capacitors with the highest level of reliability in the industry.

This new series of capacitors is suitable for use in power circuits for increasingly sophisticated communication base stations such as 5G and servers with increasing data traffic. Mass production of the new capacitors will start in December 2021.

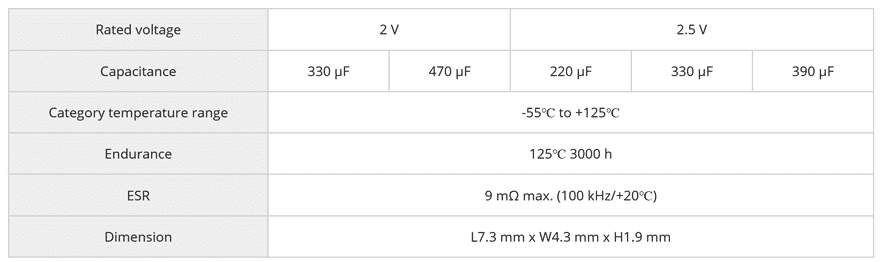

With the evolution of telecommunication equipment, high reliability capacitors with long lifetime and resistance to high humidity in addition to large capacitance are required in power supply designing. By using its proprietary conductive polymer formation technology and manufacturing process technology, Panasonic has achieved high reliability products with three times the lifespan of its existing offerings under high temperature conditions – 3,000 hours at 125℃. They also feature high durability under high temperature and high humidity conditions – 1,000 hours at 85℃/85% (dump-heat steady state). These newly developed capacitors inherit the low ESR [2] (9 mΩ / 100 kHz) and large capacitance characteristics of the SP-Cap® range of conductive polymer aluminum electrolytic capacitors, contributing to the stabilization of power supply.

Panasonic’s highly reliable JX series of SP-Cap® conductive polymer aluminum electrolytic capacitors will contribute to lowering environmental impact, as well as improving the reliability of power supply circuits.

Panasonic plans to expand product lineup of the low ESR, and a variety of the rated voltage and capacitance in JX serires.

Features:

- The highest level of reliability in the industry*1

- Long lifetime at a high temperature. Endurance of the newly developed capacitors have achieved three times the lifetime of Panasonic’s current products.

- JX series: Endurance 125℃ 3000 h

- Panasonic’s current products*2: Endurance 125℃ 1000 h

- High humidity (dump-heat)>

- JX-series: Damp-heat (steady state) 85℃ 85% 1000 h

- Panasonic’s current products*2: Damp-heat (steady state) 60℃ 90% 500 h

- Long lifetime at a high temperature. Endurance of the newly developed capacitors have achieved three times the lifetime of Panasonic’s current products.

- Excellent product characteristics (low ESR and large capacitance) that contribute to stabilizing power supply

- ESR: 9 mΩ (100 kHz, initial specification value)

After endurance ESR specification: Less than 2 times of the initial specification value

- ESR: 9 mΩ (100 kHz, initial specification value)

- Space-saving and lowering environmental impact

Notes:

*1: As conductive polymer aluminum electrolytic capacitors as of Nov. 4, 2021 (Panasonic data)

*2: Panasonic’s current products: SP-Cap® HX series

Suitable applications:

- Output-side of low voltage power rail power supply circuits employed in the ICT infrastructure industry such as communication base stations, servers, etc.

Product features:

1. The highest level of reliability in the industry

Panasonic’s SP-Cap® capacitors adopt stacking structure of capacitors elements using aluminum electrode foils. With the combination of its proprietary conductive polymer formation technology and manufacturing process technology, Panasonic has achieved a high reliability capacitors with endurance of 3,000 hours at 125℃ – three times the lifetime of the company’s existing products -– as well as durability of up to 1,000 hours at 85℃/85% (dump-heat steady state).

2. Excellent product characteristics (low ESR and large capacitance) that contribute to stabilizing power supply

The newly developed capacitors achieved low ESR (9 mΩ / 100 kHz) and large capacitance characteristics under high reliability and high temperature conditions by using Panasonic’s proprietary technology to reduce resistance of internal elements and adapting large capacitance aluminum electrode foils. In addition, from the viewpoint of high reliability, the ESR specification after the endurance is set within two times the initial specification value.

3. Space-saving and lowering environmental impact

The newly developed capacitors, with an effective capacitance equivalent to that of MLCCs, enable a reduction in the number of required capacitors. Replacing multiple MLCCs with an SP-Cap® capacitor will save space and enable the miniaturization of equipment, thereby lowering environmental impact through the reduction of materials used.