This technical blog article written by Jern Ng, KYOCERA-AVX Components Corporation, explains benefits and use of SMD Thermal Conductors for PCB heat management.

Introduction

Efforts to miniaturize electronics are becoming increasingly common as designers work to fit more components into smaller packages, offering low-weight, low-volume products.

The continuous march toward electronic miniaturization brings to light one primary challenge: the dissipation of heat. As semiconductor manufacturing realizes smaller feature sizes, microprocessor capability is simultaneously advancing with greater functionality.

The result is increased energy density and unprecedented challenges with moving heat from the core of an IC to the ambient environment. From the end-user perspective, heat management is critically important.

In some cases, processors are actively throttled to compensate for heat generation. Battery life is also negatively impacted, as is the overall form factor

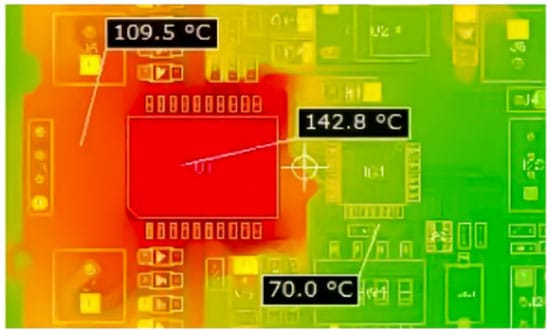

and case design. Any reduction in heat generation or improvement in heat dissipation ultimately adds significant value to the user experience. Figure 1

depicts the package temperatures of a low-power IoT board, where the surface temperatures of the main IC are more than 140ºC.

When considering thermal energy transport, designers often find themselves battling a materials science problem: thermally conductive materials are typically electrically conductive. This scenario is problematic because the electrical conductivity of these materials prevents the effective sharing of thermal domains.

For example, consider two power MOSFETs in a TO-220 package whose tabs are not isolated electrically. Each device, therefore, requires electrically isolated heatsinks with considerations for clearance, creepage, mechanical mounting, and the like. This increases costs, design effort, and overall size since the aggregate of all thermal sinks is not efficiently utilized.

Luckily, several materials exist with the unusual property of being highly thermally conductive and electrically insulative. Two of the most popular are Aluminum Nitride (AlN) and Beryllium Oxide (BeO). AlN is thermally conductive with values as high as 321 W/(m·K) and can simultaneously withstand 1.2–1.8×105 V/mm of electrical potential. Beryllium Oxide has a higher thermal conductivity than any non-metal aside from diamond and is more thermally conductive than most metals. It exhibits 330 W/(K·m) of thermal conductivity and withstands 2.7-3.1×103 V/mm of electrical voltage potential.

Using either AlN or BeO allows heat to be moved from one voltage domain to another without sacrificing much cooling efficiency. Using the previous example, two MOSFET’s with unisolated TO-220 tabs can share the same heat sink by electrically isolating them with AlN or BeO barriers. When incorporated into dedicated surface-mount packages, these materials open up a new regime of electrical design, where thermal management can be incorporated directly into the PCBA.

Q-Bridge SMD Thermal Conductors

KYOCERA AVX’s Q-Bridge SMD Thermal Conductor is an elegant and simple solution for thermal management, incorporating AlN and BeO into standard EIA packages. It is designed to channel heat away from critical circuit components effectively by connecting heat generating components to a thermal heat sink. This provides more effective thermal transfer resulting in an overall improvement in circuit performance and reliability.

The Q-Bridge can also work with PCB traces to connect a thermal heat sink where direct connections are otherwise impractical. The inherently low capacitance makes Q-Bridges virtually transparent at RF/microwave frequencies. As such, this is an excellent solution for RF PA’s, handheld radios, industrial computers, block converters, and other applications with stringent thermal requirements.

Q-Bridge is manufactured using one-piece construction, providing a RoHS compliant SMT package that is fully compatible with highspeed automated pick-and-place processing. It is available in various EIA case sizes, as shown in figure 2. Custom configurations are also available. Q-bridge devices are constructed with various termination options available, offering a thermally conductive pathway second only to diamond and enabling standard soldering and manufacturing procedures. Figure 3 presents the different termination options, case codes, and RoHS compliance.

Experimental Results

A test PCBA was constructed for a side-by-side comparison to demonstrate the effectiveness of Q-Bridge SMD Thermal Conductor devices at moving heat while maintaining electrical isolation. As shown in figure 4, two 50 ohm 1/8W resistors were mounted in series on an FR4 soft board with a thickness of 1.5mm and 1/2 oz. Copper traces. Two Q-Bridge devices were mounted between the common resistor pad and the thermal heat sink. The Q-Bridge implemented in this test is a 0603 size attached to the board with SAC-305 solder.

With ½ Watt of power dissipated in the resistors, the temperature difference with and without the Q-Bridge devices is shown in figure 5. The Q-Bridges make a dramatic difference, reducing the final resistor temperature by 18ºC.

Figure 6 the same test setup for a variety of applied powers. As can be seen, the Q-Bridge device keeps the resistors significantly cooler across the entire range of power dissipation.

Conclusions

The availability of AlN and BeO materials in standard surface-mount packages with high electrical withstand voltage has completely changed the nature of thermal management in PCB design.

Designers can efficiently transport heat to maximize heat-sink efficiency and minimize overall physical volume and cost. This improves the end user experience by ensuring that products operate at maximum performance with long battery life and attractive industrial design.

This type of design flexibility should encourage engineers to think about thermal management at every stage of the development cycle. Having a wide variety of devices to choose from with excellent performance and wide availability is a key requirement that KYOCERA AVX satisfies with its line of Q-Bridge SMD thermal conductors.