source: Airbus Defense and Space ; ESA SPCD 2018 Symposium

EPCI e-symposium library article

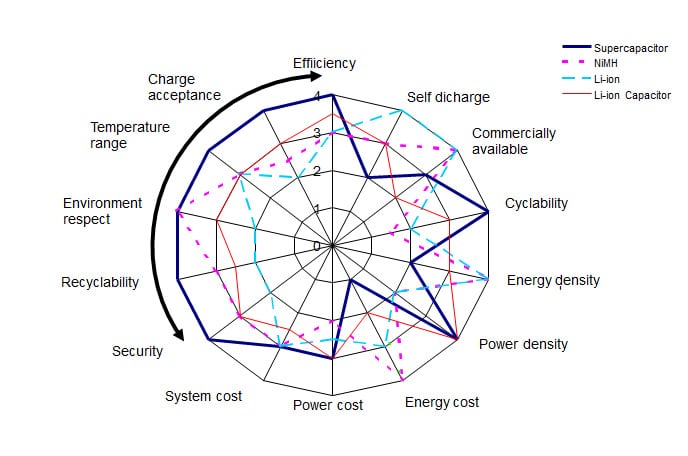

Supercapacitor is a product which fills the gap between batteries and capacitors, featuring very high power density (up to 100kW/kg) with lower stored energy than that of batteries (up to 7 Wh/kg). This technology is already widely used in various industrial, automotive and aeronautic applications.

Its fast charge and discharge time, its ability to withstand millions of charge / discharge cycles and its wide range of operational temperature (-40°C to +70°C) makes it a perfect candidate for several space applications (launchers and satellites) as demonstrated in ESA Study Contract No. 21814/08/NL/LvH entitled “High Power Battery Supercapacitor study” completed in 2010 by Airbus D&S.

From the most promising ones, it can be quoted: optimization of pyrotechnical activation system, high power mechanisms, electrical thrust vector control, high power radar supply or even hybridization of Supercapacitor banks with Li-Ion batteries. The number of known flight demonstration is very low. This is partially linked to the fact that there are currently no parts available at space grade.

This paper is focusing on small size supercapacitors enhancing power densities ≤ 15 kW/kg.

published by EPCI under approval of ESA SPCD 2018 organizing committee.

Title: Qualification of Commercial Off-The-Shelf Supercapacitors for Space Applications

Author(s): Bertrand Faure (1), Laurence Cosqueric (1), Franck De Bonet D’oleon (1), David Latif (2), Denis Lacombe (3), Brandon Bürgler (3), Marek Simcak (4)

Organisation(s): (1) Airbus Defense and Space, 31 avenue des Cosmonautes, 31402 Toulouse Cedex 4, France

(2) EGGO Space s.r.o., Dvořákova 328, 563 01 Lanškroun, Czech Republic

(3) European Space Agency (ESTEC), Keplerlaan 1, 2200AG Noordwijk, The Netherlands

(4) BD SENSORS s.r.o./ CSRC Space Division, Hradišťská 817, 687 08 Buchlovice, Czech Republic

Symposium: ESA SPCD 2018

Reference: Test, Reliability & Evaluation for space 3.

ISBN: N/A

e-Sessions Applications: Aerospace

e-Sessions Scope Components: Capacitors

e-Sessions Topics: Specification & Qualifications, Technology, Quality & Reliability

Fig. 1. Supercapacitor, a safe and efficient storage component compatible with large temperature ranges and its potential application area in space environment.

TEST CAMPAIGN OF 10F NESSCAP® SUPERCAPACITORS FOR THE ENTRY IN EPPL II

Components selected and frame of the activity

A previous activity [1] has demonstrated the interest and suitability of COTS supercapacitors for space applications. In particular, this activity has highlighted the excellent performances of the 10F components from Nesscap® in terms of ageing when submitted to life test and space environments including vacuum at both cell and system levels and enabled to identify the part as a good candidate for future space qualification.

Nesscap® is a company based in Korea which has manufactured for more than 10 years a wide range of high performances supercapacitors used in several industrial domains. Nesscap® has improved the 10F part to enhance its sealing performances including urethane coating around leads, anodization of the lead part attached to the electrode and improvement of the rubber bung. This improved XP product was released to the general public (available in mass production) in April 2016. Moreover, in case of any change in the material, process or design of the part, Nesscap® will submit a PCN for approval.

Fig. 2. Nesscap® EHSR 0010C0-002R7UC (10 F) converting to Maxwell BCAP0010 P270 X01

The current on-going activity under ESA Study Contract No. 4000115278/15/NL/GLC/fk entitled “Generic Space Qualification of 10F Nesscap Supercapacitors” consists in two main activities.

- First to perform an official test campaign on Nesscap ESHSR-0010C0-002R7UC parts in order to have the part introduced into ESA EPPL Part2.

- Second to develop and qualify the associated Bank Of SuperCapacitor, a generic and modular unit including components parallel/series arrangements compatible with several space systems.

In 2017, Maxwell acquired Nesscap. But former Nesscap products are going to be continued as before. Only the sleeve will change and both part numbers (Maxwell & Nesscap PN) will be printed. The products will stay in production in the Korea facility. The new name of the component ESHSR-0010C0-002R7UC will become BCAP0010 P270 X01 (see Fig.2.).

Screening tests

In the frame of the activity, a batch of 3.000 parts of Nesscap® EHSR 0010C0-002R7UC has been procured.

The first step of the activity consists in parts screening.

- Visual inspection

- Initial characterisation

- Vacuum exposure

- Intermediate characterisation

- Burn-in

- Final characterisation

For that purpose, EGGO Space has developed specific test facilities so that to perform the screening of a 200 parts batch in one month.

Fig. 3. EGGO supercapacitors screening facilities – burn-in (left) and vacuum (right)

Screeening status :

Screened 2400 pcs

Rejected Visual Inspection: 77 pcs

Rejected by screening : 3 pcs capacitance, 1pc ESR, 7 pcs mechanical defects

Test campaign for the entry in EPPL II

The test campaign including the tests listed hereunder are foreseen

- Initial and final electrical characterization (80 parts)

- Capacity determination

- ESR measurement (DC and AC impedance)

- leakage current

- Technology analysis assessment (5 parts):

- External inspection ESCC2263000 issue 2

- X –Ray inspection MIL STD 202 method 209

- Solderability MIL STD 202 test method 208

- Dimensions ESCC2263000 issue 2

- Resistance of the terminals MIL STD 202 method 208

- Internal visual inspection

- Outgassing test (5 parts) : ECSS-Q-ST-70-02

- Mechanical and Thermal tests (10 parts)

- X –Ray inspection MIL STD 202 method 209

- Vibration MIL STD 202 test method 204D

- Shock MIL STD 202 test method 213

- Fast temperature transients MIL STD 202 test method 107

- Seal test MIL STD 202 test method 112

- Technology analysis assessment

- Life test (60 parts)

- Calendar test (success criteria @ 2000h)

- 20 parts at 0,9*Vop and @ 50°C

- 20 parts at 0,9*Vop and @ 60°C

- Cycle life tests

- 20 parts at continuous 100% energy cycling

- Vacuum life test

- 800 parts to be tested during 18000 h in floating life test under vacuum at +55°C. at 0.85Vop

- Calendar test (success criteria @ 2000h)

All the tests have successfully been passed. The only test that is on-going is the vacuum life test on 800 parts.

Vaccum life test and reliability

The curves below, gives an overview on the life tests results on the 800 after 15000 h in floating life test under vacuum at +55°C. at 0.85Vop :

Fig. 5. DC ESR increase during vacuum life test

Fig. 6. Leakage current decrease during vacuum life test

After 11 000h of life test without failure, the reliability rate demonstrated is 32 FIT for one supercapacitor.

Next steps

The vaccum testing for MTBF determination will continue up to 18000 hours.

Two specifications are being currently written at ESCC template :

• SUPERCAPACITORS, EDLC (Electric Double Layer Capacitor) – ESCC Generic Specification

• SUPERCAPACITORS, BASED ON TYPE ESHR-0010C0-002R7UC from NESSCAP (BCAP 0010 P270 X01 from Maxwell) upscreened for space application – ESCC Detail Specification

DESIGN AND QUALIFICATION OF A BOSC BASED ON 10F NESSCAP® SUPERCAPACITORS FOR SPACE APPLICATIONS

In the frame of the project entitled “Generic Space Qualification of 10F Nesscap Supercapacitors”, a development and qualification of associated BOSC based on Nesscap 10F is on-going. A generic and modular unit including components parallel/series arrangements compatible with several space systems has been designed.

Design status

- The electrical and mechanical designs of the BOSC are completed.

- Materials and process activities are on-going

- The main BOSC performances are given in the table below:

Fig. 7. BOSC main characteristics

Electrical testing of EM BOSC

An EM BOSC has been manufactured and tested electrically.

Fig. 8. EM BOSC

The BOSC behaves as expected and the main testing conclusions are reported below:

- It was verified by the test, that NTC thermistors are functional.

- Total capacitance of the BOSC unit was measured and estimated to 0.878 F at ambient temperature.

- Balance and Serial resistances are correct values there’s no abnormal status observed.

- Capacity of each capacitors verified functionality of each capacitor separately. No problem with any cell was found.

- During inrush test, no voltage difference between each cell higher than 120 mV was recorded.

- Steady power consumption was estimated after one hour to 474,5mW at voltage level 72V.

- ESR of the BOSC was measured to 248 mΩ.

- Bonding tests verified all electrical connection between mechanical parts, maximum resistance was 1.8 mΩ at the position “Case of the connector JB3”.

- Isolation test verified that specified points have higher resistance than 100 MΩ. Capacity of the chassis to positive or negative pole was about 0.43 nF.

Materials and process activities – Background

Supercapacitors are quite sensitive components to mechanical stress, especially if applied to their leads. Some kind of mechanical fixing to the PCB had to be solved, to avoid any mechanical stress. It was quite challenging to take into account all the aspects of the specific requirements, manufacturability and repeatability of the manufacturing process, all in accordance with ECSS standards to obtain final product with maximum quality.

Potting was chosen as the only possible solution, especially due to limited physical dimensions, which were required. Potting ensures appropriate mechanical fixing of the supercapacitors and provides thermal interface to withdraw heat from the capacitors. Thermally conductive potting material can easily withdraw the supercapacitor’s heat and transfer it into the satellite structure. Heat transfer out of the BOSC unit was also crucial to consider as supercapacitors have limited operating temperature range (‐40°C up to +65°C). Keeping the temperature as low as possible also extends life of the unit and slows down the supercapacitors ageing.

… read more about potting evaluation and development in the full paper link below…

CONCLUSION AND FUTURE WORKS

The test campaign on 10F NESSCAP® supercapacitors for the entry in EPPL II is successful. The bank Of Supercapacitors based on Nesscap® is under development and will be submitted to qualifications tests.

If successful, this study will allow having the Nesscap® 10F product space qualified and available on the shelf at both component and unit levels with a TRL level of 7. The completion of the proposed study will enable new applications or developments involving supercapacitors. The proposed study appears then to be of great interest for European space industry.

The targeted customers are prime contractors or equipment manufacturers that need either a complete BOSC (from CSRC) or only screened supercapacitors components (from EGGO).

This project will put into place a European industrial supply chain for supercapacitors products at space grade that will enable its utilization for space. It will also develop skills and facilities in space developments at both CSRC and EGGO Space levels, useful for this product and for future ones.

Future industrial organization for Nesscap and BOSC procurement for space applications

Timeline for COTS supercapacitors

Next steps :

- Completion of Nesscap® ESHSR-0010C0-002R7UC ageing test under vacuum

- Completion of BOSC qualification by mid-2019

- A procurement specification at ESCC format is being established

- Ready for flight from 2019 !

REFERENCES

[1] D. Latif, “ESA contract n°1-6859/11/NL/NR – Evaluation of supercapacitors and impacts at system level – TN9 Test Report”, March 17,2014

[2] D. Latif, “ESA contract n°1-6859/11/NL/NR CCN2 – Evaluation of supercapacitors and impacts at system level – TN9 Test Report”, May 13,2016

[3] B. Buergler, E. Simon, P. Vasina, D. Latif, L. Diblik, V. Gineste, M. Simcak, 10th European Space Power Conference, ESA, Noordwijkerhout, The Netherlands, 2014.

[4] V. Sedlakova, J. Sikula, J. Majzner, P. Sedlak, T. Kuparowitz, B. Buergler, P. Vasina, “Supercapacitor equivalent electrical circuit model based on charges redistribution by diffusion”, Journal of Power Sources, 286, pp. 58-65, 2015.

read the full technical paper in pdf here:

and presentation here: