This article written by Krystof Adamek, KYOCERA-AVX Corporation explore radiation tolerance of tantalum polymer capacitors.

Environments rich in ionizing radiation create a particularly difficult functional challenge for electronic components. Spacecraft, nuclear reactors, particle accelerators, and hardened military equipment (to name a few examples) demand that their electrical systems operate correctly, even in the presence of high energy particles, cosmic rays, X-rays, and the like. Such radiation adversely affects electronics in two ways: fundamentally damaging the constituent materials, and creating transient electrical signals that can impede functionality.

Mechanisms of radiation-induced failure in semiconductors and other active devices have been well-studied, and methods for overcoming or preventing these failures have been developed. Passive devices like inductors, resistors, and capacitors, on the other hand, are less relevant from a radiation perspective due to their lack of semiconductor materials. That said, their tolerance to radiation is no less important, and it must be considered. This is especially true when new types of passive components are invented that have performance characteristics well-suited to high radiation environments. Tantalum polymer electrolytic capacitors are one such example, and demonstrating their durability for radiation hardened applications is a critical step toward their widespread adoption.

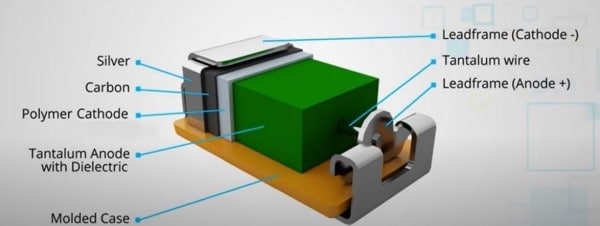

Tantalum Polymer Capacitors Construction

Tantalum capacitor construction begins with a sintered pellet of powdered tantalum submerged in an acid bath with a voltage applied across it. As a

result, an oxide layer on tantalum pentoxide quickly forms on the contoured surface of the pellet, the thickness of which is proportional to the voltage applied. This oxide acts as the dielectric insulator in the final capacitor structure, and its large effective area and high breakdown voltage yield

high reliability and high-density devices.

A cathode terminal is formed using either conventional MnO2 or a conductive polymer to sufficiently contact the oxide layer. (Petrzilek et al.) The vast majority of Tantalum electrolytics are packaged as surfacemounted devices, and an example is shown in Figure 1. Tantalum capacitors built with well established inorganic MnO2 cathodes exhibit stable, predictable behavior making them suitable for high reliability applications. Their mechanical and

electrical properties remain dependable in even the harshest of environments. Comparatively, organic polymer cathodes offer the benefit of reduced equivalent series resistance (ESR).

More importantly, their non-oxidative chemical composition limits reactivity with the tantalum under hard-surge failure conditions. These two features make polymer based capacitors ideal candidates for applications where volumetric efficiency and reliability are paramount, such as spacecraft and military equipment. Unfortunately, organic polymer cathodes come with their own set of tradeoffs. The polymer itself can suffer from oxidative degradation. It may also be damaged by water condensation inside the capacitor body, or even simple mechanical stresses.

Many of these failure mechanisms are overcome by proper physical protection and isolation from the external environment, typically through the use of a hermetic seal. In addition, Tantalum polymer capacitors suffer from a unique phenomenon referred to as “anomalous charging current” or ACC. Essentially, when the capacitor is dehumidified during storage or in the process of reflow soldering, the DC leakage current, charging current, and surge response current exhibit nonidealities and reduced performance. Luckily, the ACC phenomenon is not permanent and can be rectified through advanced materials and processing (Freeman et al.)

Radiation Testing

To test the latest Tantalum polymer capacitor technology for radiation tolerance, a very specialized laboratory is required. Deep within the Vitkov Hill in the center of Prague lies an esoteric testing facility for just such endeavors operated by the Czech Academy of Sciences (CAS). Shown in the

figure below, the radiation laboratory is accessed from an old pedestrian tunnel, which leads to a very unique piece of equipment: the Microtron

MT25.

The MT25 is a cyclic electron accelerator with a Kapitza resonator, capable of energizing electrons in bunches at levels scaled by 1MeV steps from

6 MeV to 25 MeV. The electrons are accelerated by an RF electric field of constant amplitude and frequency in a constant uniform magnetic field. The

output of the accelerator is actually a photon beam or Bremsstrahlung. This is an electromagnetic radiation produced by the deceleration of electrons passed through a tungsten target placed behind the exit window. A schematic of the MT25 is shown in the figure below (“Microtron MT25”).

Compared to a proton, the electrons manipulated by the microtron are about 1,000 times lighter. The imparted energy onto an irradiated sample

is therefore also orders of magnitude smaller. For many types of testing, this is a desirable quality because only chemical changes occur during the

reaction. No nuclear activity is induced and as such no radioactivity is imparted onto the device under test (DUT). The microtron also offers excellent control configurability of the total radiation dose.

Tantalum MnO2 (TRJD226K035SRJV 7343-31) and. Tantalum polymer (TCQB476M006R070E 3528-21, TCQU107M025R070E 7361-43) capacitors were soldered onto a custom FR5 PCB in an array for irradiation and characterization. Each group was exposed to three different radiation doses, with and without bias voltage applied, as shown in Figure 3.

After each radiation dose, the bulk capacitance, ESR, dissipation factor (DF), and DC leakage current (DCL) are measured across the devices in the array. Bulk capacitance and DF are measured at 120Hz and 2.2 V bias, ESR at 100kHz and 2.2 V bias, and DCL at 300s and rated voltage. In addition, a 24 hour high temperature annealing period was included as the final stage in the testing cycle. By observing any changes in these parameters across radiation dosing, one can ascertain the resilience of the device in the presence of ionizing radiation.

Results of Testing and Discussion

For Tantalum polymer capacitors, no appreciable change in any of the measured parameters across all of the radiation levels and the annealing period was observed. Similarly, for MnO2 based cathodes, there was minimal deviation from the baseline values. These results are presented in Figure 4 and 5 and quantitatively capture the ability of these Tantalum devices to operate in the presence of radiation.

While there was no change in the electrical parameters for the tested devices, some of the polymer based capacitors did exhibit an anomalous charging current (ACC) after the annealing process. This is shown in Figure 6.

It is believed that this change in charging current is due to the absence of moisture in the polymeric materials due to dehumidified storage or the

soldering process. Traces of water and higher temperatures tend to increase flexibility in the polymer chain, and that increased flexibility in

combination with an applied voltage can lead to reorganization of the polymer in such a way to alter current flow. In general, these changes do not

relate to radiation exposure and are not significant to the functionality of the capacitor.

It is also important to note that all of the devices were tested with and without DC bias. In both cases, the same tolerance to radiation was visible

with almost no correlation between the electrical parameters and the radiation dose.

Overall, all of the Tantalum capacitors tested exhibited excellent radiation tolerance. Given that the polymer based devices offer significant

performance advantages like high volumetric efficiency, low ESR, and long lifetime with selfhealing properties, it is clear that using them in

military and space applications is appropriate.

References

Freeman, Y., Alapatt, G.F., Harrell, W.R., Luzinov, I., Lessner, P., & Qazi, J. (2013). Anomalous Currents in Low Voltage Polymer Tantalum Capacitors. ECS Journal of Solid State Science and Technology, 2(11), N197-N204.

Microtron MT25. (n.d.). Ústav jaderné fyziky AV ČR. Retrieved November 13, 2022, from http://www.ujf.cas.cz/en/departments/department-ofaccelerators/microtron/

Petrzilek, J., Uher, M., & Biler, M. (2016). Polymer Tantalum Capacitors for Advanced High Reliability Applications. SPCD