Researchers led by Energy Sciences Division DEVCOM Army Research Laboratory Adelphi, USA published in Energy Technology Journal its findings on ALD-based antiferroelectric-coated metal foam infiltrated with liquid metal as a capacitor dielectric.

Abstract

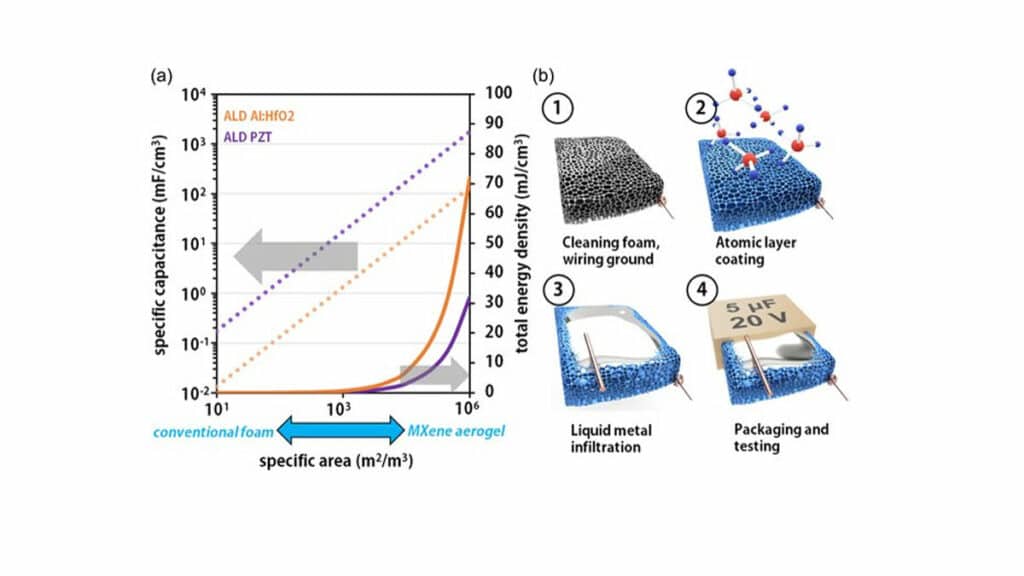

Nickel metal foams serve as both a substrate and bottom electrode for a dielectric capacitor using atomic-layer deposition (ALD) and a eutectic gallium–indium (EGaIn) liquid metal (LQM) counter electrode.

The conformal dielectric has acomposition of 6.25% Al–HfO2 in the antiferroelectric phase, confirmed with polarization versus electric field measurements. Liquid EGaIn is pressure-infill-treated within the coated foams to form the dielectric capacitor. Capacitances up to 4 μF are realized.

Calorimetry of the infiltrated capacitor shows a 60 J g-1 latent heat upon melting a frozen EGaIn electrode, suggesting that the phase change can alleviate thermal deviations from pulsed power capacitor operation.

Infiltrated capacitors are also shown to survive bending and freeze-thaw cycles. The metal foam–ALD dielectric–LQM capacitor shows a combined set of thermal and electrical properties not available in other classes of capacitors.

Introduction

Recent work on atomic-layer deposition (ALD)-grown dielectrics instead uses higher permittivity, ultrathin films, sometimes on microfabricated high-surface-area substrates. To reach high power, these approaches rely on high capacitive charge storage, rather than the high voltage in polymer capacitors. The challenge with this approach is that the ALDed electrodes, usually thin (<100 nm)TiN or Pt are insufficient current conductors for pulsed power applications.

Approaches are needed that combine the seemingly incompatible needs of high surface area and high electrical conductivity. The conformality inherent to the ALD process lent itself early on to dielectric capacitor applications. Banarjee et al. created a high-surface-area substrate through anodic etching of aluminum and then fabricated a capacitor structure through successive metal–dielectric–metal ALDs, reaching an areal capacitance density of 100 μF cm2, although the equivalent series resistance of the capacitor was never presented. This is compared to a commercially packaged device having an areal density of 0.877 μF cm2.

In 2011, ferroelectricity was discovered in fluorite-structured ALDed silicon-doped HfO2, and soon after, antiferroelectric-like variants were discovered. AFE has been considered for energy storage since its discovery in the 1960s. This is due to the unique property of having an accessible (sub-breakdown) electric field-induced, first-order phase transition, allowing latent electrical energy to be stored in the crystal structure.

Read the Full article: An Antiferroelectric‐Coated Metal Foam Infiltrated with Liquid Metal as a Dielectric Capacitor . Available from: https://www.researchgate.net/publication/384692586_An_Antiferroelectric-Coated_Metal_Foam_Infiltrated_with_Liquid_Metal_as_a_Dielectric_Capacitor