Chinese researchers have fabricated a ferroelectric ceramic dielectric material with reduced grain size for improved energy storage capability. This research has been published in the journal of Chemical Engineering Journal.

NBT and NBST dielectric materials

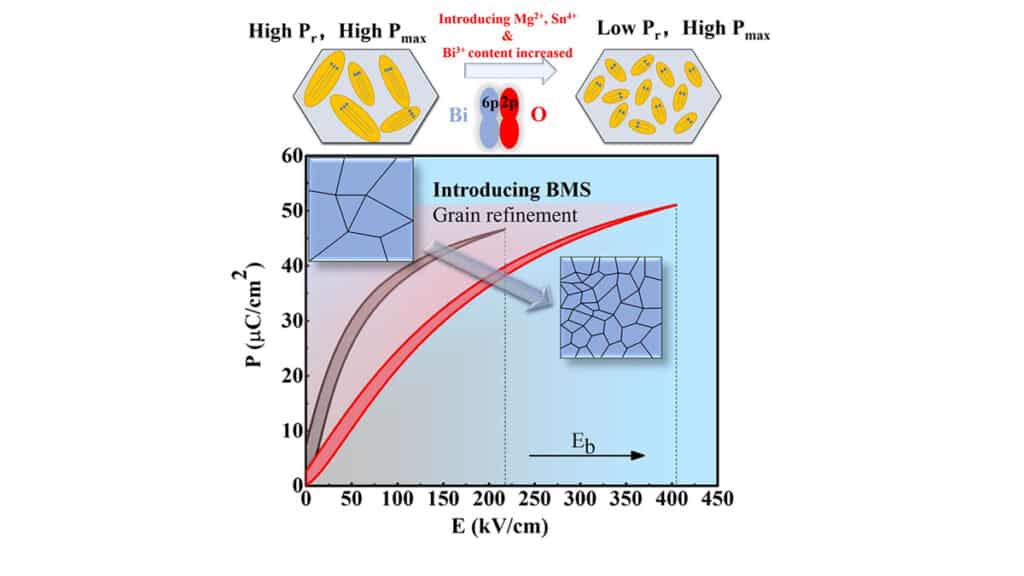

(Na0.5Bi0.5)TiO3 (NBT)-based ferroelectrics have very high Curie point (Tc = ~320◦C) and large maximum polarization (Pmax) of over 40 μC/cm2. However, NBT ceramics have low energy storage efficiency due to their high remnant polarization (Pr), which severely hampers its energy storage performance. Many researchers have tried to destroy the long-range order of ferroelectrics such as NBT-based ceramics by doping with various chemical reagents to make them behave like a relaxor ferroelectric with a reduced remnant polarization.

The researchers added linear dielectrics such as SrTiO3 and antiferroelectric additives such as NaNbO3 as modifiers in NBT-based ceramic. The resulting (Na0.5Bi0.5)0.7 Sr0.3TiO3 (NBST) exhibited enhanced recoverable energy density, efficiency, and slender polarization vs electric field loop.

Out of several compositions of ((1-x) NBST-xBMS, 0 ≤ x ≤ 0.15), optimal energy-storage performances were achieved for 0.9NBST-0.1BMS composition. 0.9NBST-0.1BMS has a perovskite structure with no impurities. However, impurities start to appear for the 0.85NBST-0.15BMS samples and above i.e. (x>0.15), due to the decreasing solubility of BMS in NBST.

The presence of Mg2+ and Sn4+ in B-sites effectively destroyed the long-range order of 0.9NBST-0.1BMS ferroelectric, thus resulting in a weak coupling structure, which improved energy storage efficiency. It also showed high-temperature stability and frequency insensitivity of recovery energy density and efficiency, which is crucial for normal work at elevated temperatures. Additionally, the additive BMS significantly reduced the grain size of the ceramic, which increased the breakdown field.

It was observed that with the increase of BMS content, both maximum polarization (Pmax) and remnant polarization (Pr) decreased, and the polarization-electric field hysteresis loop became slender, which is beneficial to enhance energy storage performance.

Highlights of the new material:

- 0.9NBST-0.1BMS lead-free ceramics with Wrec = 6.68 J/cm3 and η = 89.1 % were designed and fabricated.

- Small grain size and high activation energy of grain boundary leads to high breakdown field (405 kV/cm).

- The energy storage potential (Wrec/Eb) is up to 0.01649 μC/cm2.

- Excellent fatigue endurance over 105 electrical cycles (the Wrec variation is less than 1.5%).

Abstract

Ferroelectric ceramics, as a potential candidate for high-power energy storage capacitors, lies in their excellent recoverable energy storage density (Wrec) and outstanding efficiency (η) in practical applications. Herein, a new type of lead-free ceramics (1-x)(Na0.5Bi0.5)0.65Sr0.35TiO3–xBiMg0.5Sn0.5O3 or (1-x)NBST-xBMS was prepared with the aim of enhancing the breakdown strength (Eb) and reducing the energy storage loss through grain refinement. It was found that Eb of 0.9NBST-0.1BMS reaches 405 kV/cm due to the reduction in the grain size of ceramic and thus the extremely high ratio of grain boundary resistance to grain resistance.

Besides, a remarkable energy-storage performance was obtained, that is, Wrec and η are ∼ 6.68 J/cm3 and 89.1% at 405 kV/cm, respectively, along with excellent stability in terms of frequency, temperature, and fatigue endurance. The outstanding energy-storage performance is resulted from modulating the grain size via doping the moderate content of Bi3+ and Mg2+/Sn4+, which is beneficial to increase the breakdown field by increasing resistivity under high electric field while increasing the grain boundary activation energy and promote the formation of a relaxor state at the same time. More importantly, energy storage potential (defined as Wrec/Eb) is up to 0.01649 μC/cm2, being the highest value reported so far for BNT-based ceramics in energy-storage application. Our results pave the way for practical applications of NBST-based ferroelectric capacitors with excellent energy storage performance.

Reference

Y. Gao, X. Zhu, B. Yang, P. Shi, R. Kang, Y. Yuan, Q. Liu, M. Wu, J. Gao, X. Lou, Grain size modulated (Na0.5Bi0.5)0.65Sr0.35TiO3-based ceramics with enhanced energy storage properties, Chemical Engineering Journal, 2021, 133584. https://doi.org/10.1016/j.cej.2021.133584