This article delves into a comprehensive comparison of linear and switching regulators, examining their advantages, limitations, and suitability for different applications. Additionally, it explores how these regulators interact with passive components in power conversion circuits.

The overall power architecture of a system depends on how voltage regulation is implemented, making the choice between linear and switching converter regulators essential. Read more in this article.

Key Takeaways

- The choice between linear and switching regulators determines a system’s efficiency, thermal management, and noise performance.

- Linear regulators provide low noise and a simple design but are less efficient for large voltage drops.

- Switching regulators achieve high efficiency and scalability, making them suitable for high-power applications.

- Both types rely on passive components like capacitors and inductors for stability and noise suppression.

- Evaluating performance parameters is crucial for selecting the right regulator for your application.

Power regulation goes beyond simply converting voltage; it involves managing energy flow to minimize losses, reduce heat, and maintain system stability. Whether designing for low-power portable devices or high-efficiency industrial systems, selecting the appropriate voltage regulation approach is paramount.

Passive components like capacitors, inductors, resistors, and transformers play a crucial role in power conversion by providing energy storage, filtering, and noise suppression.

Choosing the wrong regulator can have severe consequences. Excessive heat, reduced efficiency, and electromagnetic interference (EMI) issues can all arise from an ineffective power conversion strategy.

Voltage regulation ensures that the output voltage remains stable despite fluctuations in the input voltage or variations in load conditions. Without proper regulation, components may overheat, experience voltage stress, or fail prematurely.

The selection of a power converter—switching or linear—fundamentally influences the efficiency, thermal management, noise performance, and reliability of modern electronic systems. This white paper offers a thorough comparison between switching and linear regulators, addressing operational principles, application considerations, and key selection criteria for engineers seeking the optimal solution.

Power Regulation Essentials

Power regulation is more than voltage conversion. It orchestrates energy flow to minimize losses, suppress heat generation, and stabilize system performance. Effective regulation ensures consistent output voltage despite fluctuations in input or load, protecting sensitive components and prolonging system lifetime.

Key Performance Parameters

- Load Regulation: Maintains output stability under changing loads.

- Line Regulation: Holds voltage constant despite variations in input supply.

- Efficiency: Ratio of useful output to input power—critical for energy and thermal impacts.

- Transient Response: Speed of output stabilization after sudden load changes.

- Thermal Dissipation: Heat generated from power losses—must be managed for reliability.

Linear Regulators: Simplicity and Clean Output

Operating Principle

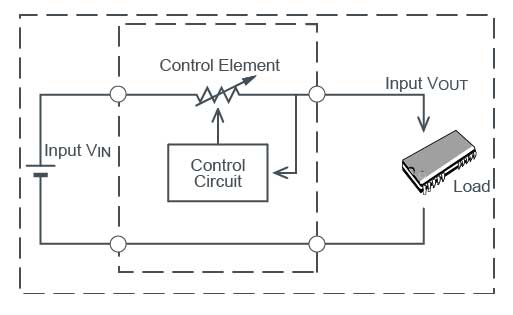

Linear regulators use a continuously adjustable pass element (such as a MOSFET or BJT) to keep output voltage steady. Excess input voltage is simply dissipated as heat. Standard and low-dropout (LDO) variants offer flexibility for different supply conditions but generally suffer significant efficiency losses when dropping high voltages.

Advantages

- Minimal output noise and ripple—ideal for sensitive analog/RF applications

- Straightforward design with few external parts

- Fast transient response to load changes

Limitations

- Inefficient for large voltage drops—proportional heat dissipation

- Current capability limited by thermal constraints

- Heatsinks often required for higher currents

Typical Applications

- Operational amplifiers, ADCs/DACs

- RF front-ends

- Post-regulation after DC-DC conversion

Switching Regulators: Efficiency and Scalability

Operating Principle

Switching regulators (buck, boost, buck-boost, flyback) use high-frequency switching—controlling MOSFETs or IGBTs through pulse-width modulation (PWM). Energy is transferred and temporarily stored in inductors/transformers, then released to the load, allowing high efficiency (often up to 98%) with controlled step-up or step-down conversion.

Advantages

- Very high efficiency, especially for large input-output voltage differences

- Reduced thermal dissipation—smaller form factors possible

- Suitable for high-power and battery-operated designs

Limitations

- Complex design—need for compensation networks, passive filtering

- EMI generation—requires careful PCB layout and shielding

- Slower transient response compared to linear

Typical Applications

- Laptops, smartphones, portable devices

- Industrial and telecom systems

- Renewable energy, power conversion infrastructure

Thermal Management and Efficiency vs Noise

Linear regulators dissipate input-output voltage difference as heat, demanding effective cooling solutions in high-current circuits. Switching converters, due to their efficiency, generate less heat, enabling denser layouts but requiring attention to EMI control.

Noise-sensitive circuits should prefer linear regulation, while efficiency-driven or high-power circuits benefit from switching architectures.

Cost and Component Count

Linear regulators are cost-effective for simple needs, reducing bill-of-materials (BOM) and layout complexity. Switching regulators, though initially more expensive and complex, offer longer-term energy savings, especially in battery-dependent applications.

Passive Components in Power Conversion

- Both regulator types rely fundamentally on capacitors (for stability, filtering) and, for switchers, inductors/transformers (energy storage, EMI suppression).

- Switching designs necessitate careful selection and placement of filter caps/inductors for optimal performance and noise management.

Comparative Summary Table

| Criteria | Linear Regulator | Switching Regulator |

|---|---|---|

| Efficiency | Low (Heat Dissipated) | High (Up to 98%) |

| Noise & EMI | Very Low | Requires Filtering |

| Complexity | Simple Design | More Components, Control Loops |

| Thermal Dissipation | High (Needs Heatsink) | Low (Efficient Operation) |

| Best Use Case | Noise-Sensitive Analog/RF | High Power, Efficiency-Critical |

Conclusion: Making the Right Choice

The right voltage regulator balances efficiency, noise performance, thermal constraints, and design complexity.

Linear regulators excel in low-noise, sensitive applications; switching regulators deliver advantages where efficiency and power scalability matter. They are favored for their simplicity and low noise, making them ideal for RF and analog applications. Switching regulators, on the other hand, provide high efficiency and scalability, making them suitable for high-power applications where energy conservation is critical.

The choice between a switching and linear regulator depends on the specific use case and the trade-off between efficiency and noise.

References and Further Reading

- Selection of Storage Inductors for DC/DC Converters

- Input filters for DC/DC converters

- Buck Converter Design and Calculation

- SEPIC Converter Design and Calculation

- Boost Converter Design and Calculation

- Flyback Converter Design and Calculation

- Fly-Buck Converter Explained and Comparison to Flyback

- LLC Resonant Converter Design and Calculation

- How to Calculate the Output Capacitor for a Switching Power Supply

Frequently Asked Questions: Switching vs Linear Power Regulators

Linear regulators use a continuously adjustable pass element (MOSFET or BJT) to maintain stable output voltage by dissipating excess input voltage as heat. Switching regulators use high-frequency switching with pulse-width modulation (PWM) to transfer energy through inductors/transformers, achieving efficiency up to 98% with minimal heat dissipation.

Linear regulators are ideal for noise-sensitive analog and RF applications, operational amplifiers, ADCs/DACs, RF front-ends, and post-regulation after DC-DC conversion. They offer minimal output noise and ripple, straightforward design with few external parts, and fast transient response to load changes.

Switching regulators provide very high efficiency (up to 98%), especially for large input-output voltage differences, reduced thermal dissipation allowing smaller form factors, and suitability for high-power and battery-operated designs. They are commonly used in laptops, smartphones, portable devices, industrial and telecom systems, and renewable energy applications.

Linear regulators are inefficient for large voltage drops with proportional heat dissipation, have current capability limited by thermal constraints, and often require heatsinks for higher currents. Their efficiency decreases significantly when dropping high voltages.

Yes, switching regulators generate EMI due to their high-frequency switching operation. They require careful PCB layout, shielding, and passive filtering to manage EMI. Additionally, switching regulators have slower transient response compared to linear regulators and require more complex design with compensation networks.

Linear regulators are initially more cost-effective for simple applications, reducing bill-of-materials (BOM) and layout complexity. However, switching regulators, though initially more expensive and complex, offer longer-term energy savings, especially in battery-dependent applications where efficiency is critical.

Both regulator types rely fundamentally on capacitors for stability and filtering. Switching designs additionally require inductors and transformers for energy storage and EMI suppression. Careful selection and placement of filter capacitors and inductors is essential for optimal performance and noise management in switching regulators.

Linear regulators dissipate the input-output voltage difference as heat, demanding effective cooling solutions in high-current circuits. Switching converters generate less heat due to their high efficiency, enabling denser layouts but requiring attention to EMI control. Proper thermal management ensures system reliability and longevity.

How to Choose Between Switching and Linear Power Regulators

- Evaluate Your Application Requirements

Determine the key performance parameters for your application: load regulation needs, line regulation requirements, required efficiency levels, transient response speed, and thermal dissipation constraints. Identify whether your application is noise-sensitive (analog/RF circuits) or efficiency-critical (battery-powered devices).

- Assess Input and Output Voltage Specifications

Calculate the voltage drop between input and output. For large voltage differences, switching regulators offer significantly better efficiency. For smaller voltage drops with low current requirements, linear regulators may be more practical and simpler to implement.

- Consider Noise and EMI Requirements

If your application involves sensitive analog circuits, RF front-ends, or precision measurement systems, prioritize linear regulators for their minimal output noise and ripple. For applications where noise is less critical, switching regulators can provide excellent efficiency benefits.

- Analyze Power and Current Requirements

For high-power applications (laptops, industrial systems, telecom equipment), switching regulators are the preferred choice due to their scalability and efficiency. For low-power, noise-sensitive applications, linear regulators excel despite lower efficiency.

- Evaluate Thermal Management Capabilities

Consider available board space for heat dissipation. Linear regulators may require substantial heatsinks for high-current applications. Switching regulators generate less heat but need careful PCB layout and may require electromagnetic shielding.

- Calculate Design Complexity and Cost

Linear regulators offer simple designs with fewer external components, reducing initial design complexity and BOM costs. Switching regulators require more components (inductors, transformers, compensation networks) and complex control loops but provide long-term energy savings.

- Select Appropriate Passive Components

For linear regulators, choose high-quality capacitors for output stability and filtering. For switching regulators, carefully select inductors/transformers for energy storage, along with filter capacitors for EMI suppression. Component placement and PCB layout are critical for switching regulator performance.

- Verify Transient Response Performance

Linear regulators provide fast transient response to sudden load changes, ideal for applications with dynamic loads. Switching regulators have slower transient response but can be optimized through proper compensation network design.

- Make Your Final Decision

Balance efficiency, noise performance, thermal constraints, and design complexity. Choose linear regulators for low-noise, sensitive applications where simplicity matters. Select switching regulators where efficiency, power scalability, and energy conservation are critical priorities.