The ability of tantalum capacitors to answer requirements for reliability, robustness and high energy density make them critically important for advanced medical applications such as lung ventilators and life support monitoring equipment. EPCI president Tomas Zednicek published an article tracking use of tantalum capacitors in lung ventilators. The article was published by T.I.C. Bulletin No. 181 in April 2020.

Medical ventilators provide assistance for hospital patients suffering with breathing difficulties; critically important today for patients around the world suffering from critical stages of Covid-19.

This was also emphasized on April 1st 2020 when the European Passive Components Industry Association (EPCIA) and German Electrical and Electronic Manufacturers ́ Association (ZVEI) issued a joint request that countries classify the passive components supply chain as a “key” industry operation which must continue during the crisis:

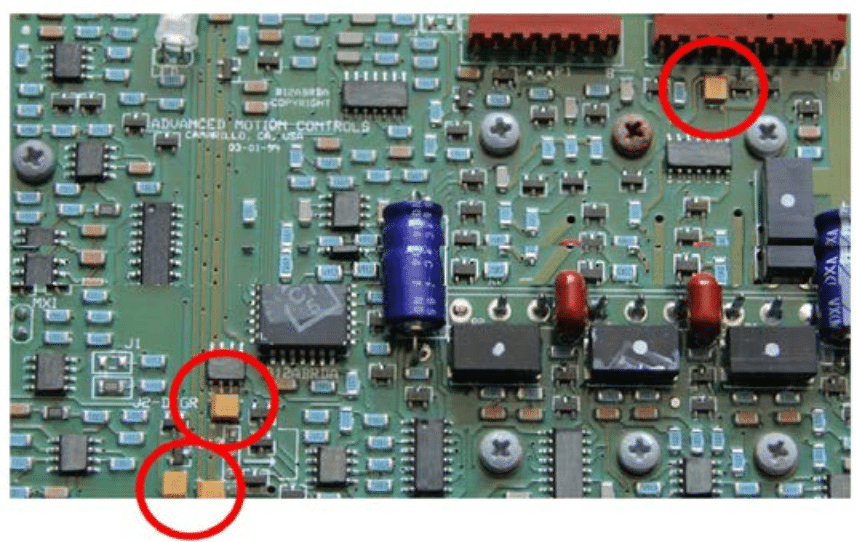

Motor Controller

High performance ventilator requires stable and reliable computerized turbine control to match synchronization with patient’s efforts. Tantalum capacitors on board of brushless motor controller assist to drive precise rotational velocity and direction control of scroll compressor. (Fig.1.)

Main control processing unit (CPU) board

The main CPU is the ‘brain’ of the system; it requires fast processing with reliable continuous operation. There are multiple input and output circuits, processor coupling and local DC/DC converters that require a long operating life and stable operating conditions. They are supported by tantalum capacitors (see Figure 2).

High accuracy analogue measurement boards

Control accuracy and the precise response of medical devices also depends on reliable measurement and conversion of AC voltage and current inputs from the patient monitoring sensors. Texas Instruments TI TIDA-01214 is an example of isolated 16-Bit ADC, high-accuracy analog input module with improved trip time performance and reliability suitable for medical applications (see Figure 3). The alarm feature is designed to identify the AC analog input faults on a sample basis for faster fault detection.

Main power board and DC/DC Converters

The continuous uninterrupted operation of medical devices depends on the main power supply and the local DC/DC converters to supply a wide range of functionalities. A number of such power supply designs depend, among other components, on the reliability of tantalum capacitors. Figure 4 demonstrates use of tantalum capacitors with DC/DC step down switching regulator LT1374 on a medical board.

Summary and Conclusion

Tantalum capacitors play a critically important role in medical applications, including life support monitoring equipment and lung ventilators. Today, more than ever, tantalum capacitors are vital in the urgent struggle of healthcare institutions and healthcare professionals battling the global Covid-19 pandemic. Tantalum capacitor manufacturers are faced with increased customer demand for critical medical equipment including lung ventilators, mobile X-ray, CT systems, ultrasound and patient monitors. All current efforts are focused on ensuring the delivery of parts as soon as possible, with shortest possible lead-times.

Tantalum capacitor industry and manufacturers responded adequately with priority in manufacturing and delivery to medical industry as an released example by AVX below: