Source: Vishay news

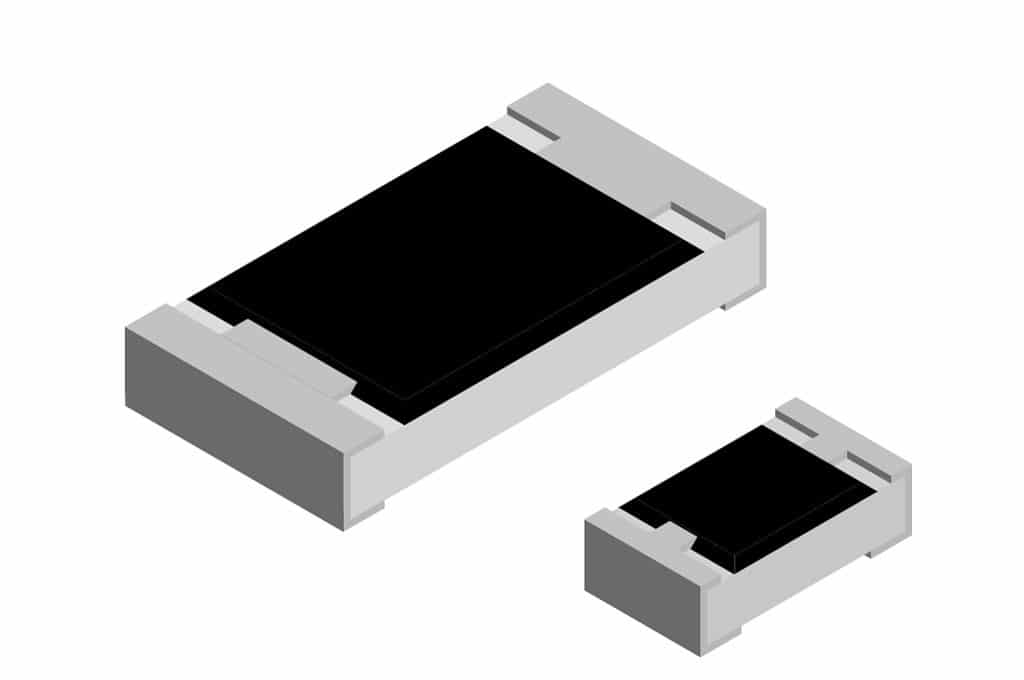

Vishay Low Ohmic Value RCWE Sulfur Resistance Exceeds ASTM B809-95.

High sulfur environments can occur in a variety of situations such as in countries that use sulfur rich coal for power generation, industrial environments, hot enclosed spaces with vulcanized rubber, and many others.

Sulfur gas can enter through openings in the epoxy coating of commodity thick film chips to attack the thin silver attach layer that connects the resistance element to the terminal. Over time the

thin silver attach layer reacts with sulfur to form Silver Sulfide that causes resistance values to slowly shift and eventually open.

Vishay Dale has tested the RCWE to be resistant to sulfur environments. ASTM B809-95 is typically the test standard referenced for sulfur resistance performance, but Vishay has developed an accelerated life test that evaluates the RCWE sulfur resistance at a higher temperature and over a longer period. The Vishay test evaluates performance at 90 °C instead of 60 °C, which is 9 times more aggressive. The duration is increased to 1000 hours. The RCWE series passes the more rigorous test conditions.

Test Conditions

ASTM B809-95:

Duration: 24 hours

Temperature 50 °C

Resistance Change limit 1.0 %

Vishay:

Duration: 1,000 hours

Temperature: 90 °C

Resistance Change limit: 0.5 %

RCWE Key Features

- Sulfur resistant

- Low resistance values down to 0.01Ω

- Low TCR down to 100 ppm

- Tight tolerance of 0.5%