Source: Vishay Technical Note

Vishay Intertechnology, Inc. just released a new technical note on Wet Electrolyte Tantalum Capacitors Introduction to the Basics.By Mike Mosier

INTRODUCTION

Tantalum electrolytic capacitors are the preferred choice in applications where volumetric efficiency, stable electrical parameters, high reliability and long service life are the primary considerations. The stability and resistance to elevated temperatures of the tantalum/tantalum oxide system make wet tantalum capacitors an appropriate choice for today’s technology.

Vishay is a pioneer and leader in this field, producing a large variety of tantalum capacitor types for industrial, military and aerospace electronic applications. Tantalum is not found in its pure state. Rather, it is commonly found in a number of oxide minerals, often in combination with Columbium ore. This combination is known as tantalite when its contents are more than one-half tantalum. Important sources of tantalite include Australia, Brazil, Canada, China, and several African countries.

Synthetic tantalite concentrates produced from tin slags in Thailand, Malaysia, and Brazil are also a significant raw material for tantalum production. Electronic applications and particularly capacitors consume the largest share of world tantalum production. Other important applications for tantalum include cutting tools (tantalum carbide), high temperature super alloys, chemical processing equipment, medical implants, and military ordnance. Vishay is a major user of tantalum materials in the form of powder and wire for capacitor elements and rod and sheet for high temperature vacuum processing.

THE BASICS OF TANTALUM CAPACITOR TECHNOLOGY

Most metals form crystalline oxides which are non-protecting, such as rust on iron or black oxide on copper. A few metals form dense, stable, tightly adhering, electrically insulating oxides. These are the so-called valve metals and include titanium, zirconium, niobium, tantalum, hafnium, and aluminum. Only a few of these permit the accurate control of oxide thickness by electrochemical

means. Of these, the most valuable for the electronics industry are aluminum and tantalum.

Wet tantalum capacitors are basic to all kinds of electrical equipment from satellites, aerospace, airborne, military ground support, oil exploration, and power supplies. Their function is to store an electrical charge for later use. Capacitors consist of two conducting surfaces, usually metal plates, whose function is to conduct electricity. An insulating material or dielectric separates them. The dielectric used in all tantalum electrolytic capacitors is tantalum pentoxide.

Tantalum pentoxide compound possesses high dielectric strength and a high dielectric constant. As capacitors are being manufactured, a film of tantalum pentoxide is applied to their electrodes by means of an electronic process. The film is applied in various thicknesses and at various voltages and although transparent to begin with, it takes on different colors as light refracts through it. This coloring occurs on the tantalum electrodes of all types of tantalum capacitors. Rating for rating, tantalum capacitors tend to have as much as three times better capacitance / volume efficiency than aluminum electrolytic capacitors.

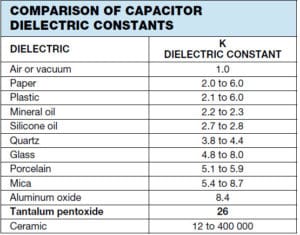

An approximation of the capacitance / volume efficiency of other types of capacitors may be inferred from the table on right, which shows the dielectric constant ranges of the various materials used in each type. Note that tantalum pentoxide has a dielectric constant of 26, some three times greater than that of aluminum oxide. This, in addition to the fact that extremely thin films can be deposited during the electrolytic process mentioned earlier, makes the tantalum capacitor extremely efficient with respect to the number of microfarads available per unit volume. The surface area of the two conducting plates determines the capacitance of any capacitor, the distance between the plates, and the dielectric constant of the insulating material between the plates.

In the tantalum electrolytic capacitor, the distance between the plates is very small since it is only the thickness of the tantalum pentoxide film. As the dielectric constant of the tantalum pentoxide is high, the capacitance of a tantalum capacitor is high if the area of the plates is large:

,where C = capacitance e = dielectric constant A = surface area of the dielectric t = thickness of the dielectric

The liquid electrolyte in wet slug capacitor, along with the case, forms the cathode (negative) plate. The anode lead wire consists of two pieces. A tantalum lead embedded in the pellet, which is in turn connected to a termination or lead wire. The cross section drawings clearly show the construction details of the various wet tantalum capacitors.

WET ELECTROLYTE TANTALUM CAPACITORS

Wet electrolyte, sintered anode tantalum capacitors often called wet slug tantalum capacitors, use a pellet of sintered tantalum power to which a lead has been attached. Tantalum powder of suitable fineness, sometimes mixed with binding agents, is mechanically pressed into pellets.

The lead is embedded during pressing of the pellet. The next step is a sintering operation in which binders, impurities and contaminants are vaporized and the tantalum particles are sintered into a porous mass with a very large surface area.

A film of tantalum pentoxide is electrochemically formed on the surface areas of the fused tantalum particles. Provided sufficient time and current is available, the oxide will grow to a thickness determined by the applied voltage.

The pellet is then inserted into a tantalum or silver can, which contains an electrolyte solution, A suitable end seal arrangement prevents the loss of the electrolyte. Wet slug tantalum capacitors are manufactured in a voltage range up to 125 VDC.

The Vishay SuperTan® represents a major breakthrough in tantalum electrolyte capacitor design. The SuperTan design dramatically increased the available capacitance in each of the four standard cased sizes. It provides two to three times more capacitance per unit volume while substantially increasing ripple current capability as well as reduced ESR.

In airborne, aerospace, satellite and smart munitions applications where size and weight are the primary considerations, SuperTan is the preferred capacitor style for the energy storage, voltage hold-up, timing and filtering circuit design. With these circuit functions in mind, along with long-term shelf life, operation life and reliability, SuperTan provides the circuit designer a solution to many of the problems that previously were resolved with marginally reliable and ineffective size options.

SuperTan is available to the military sector on a DLA approved drawing (93026) as well to the commercial sector as a standard device.

TANTALUM CAPACITORS FOR ALL DESIGN CONSIDERATIONS

In choosing between the solid or wet style of tantalum capacitor, the circuit designer customarily uses wet tantalum capacitors, where the lowest DC leakage is required. The conventional silver can design will not tolerate any reverse voltages. In military or aerospace applications, tantalum cases units are used in place of silver cases where the utmost reliability is desired. The tantalum cased styles, CLR79 and CLR81, will withstand reverse voltages up to 3 V. They will operate under higher ripple currents and can be used at temperatures up to +392 °F (+200 °C).

Full technical note paper can be downloaded in pdf from Vishay website here.

featured article, figures and image source credit: Vishay Intertechnology, Inc.