This article based on SRT Resistor Technology application note explains what is voltage coefficient of resistance, how to measure it and why it is of key importance in specific applications.

Voltage Coefficient of Resistance (Vcr) – Definition

The voltage coefficient of resistance (=Vcr), which is barely encountered at resistance values below 10MOhm, is a non-linear feature of resistors mainly at very high values.

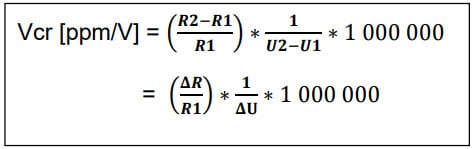

Analog to the Tcr, which indicates the change of resistance with temperature, the Vcr reveals the change of resistance with applied voltage.

These resistors are non-ohmic resistors which means that the ratio between applied voltage and measured current is no longer constant for every voltage. So strictly speaking, if you use the well-known formula:

R = U / I

you have to specify the voltage at which you measure the resistance (which is not necessary for true ohmic resistors). The calculation of the Vcr is completely analogous to the calculation of the Tcr, you just have to replace the temperatures with the voltages:

R1 = resistance value at voltage U1

R2 = resistance value at voltage U2

Exactly speaking (and this is valid for the Tcr too) this calculus is just the linear interpolation between the two measurement points at U1 and U2 (green straight line in the graph below). The real behaviour is nonlinear and could look like the one which is shown with the blue curve in the graph or similar.

If you rearrange the formula from above a little bit, you see that the Vcr is nothing else but the gradient or slope of R with V normalised to R1. It is easy to see in the graph on Figure 1. below, that the Vcr between 25V and 50V may be considerably different to the Vcr between 100V and 125V, albeit the voltage difference is in both cases ΔU = 25V.

Also, you see that when measuring the Vcr the exact value of the slope is important, and this is achieved by a big distance between the measurement voltages. Then small measurement errors of the resistance do not have such an influence.

Usually, the voltage coefficient is indicated in parts per million per volts [ppm/V] or also in percent per volt [%/V]; thick film resistors with ruthenium-oxide based conducting phase have negative Vcr’s. One example to see it more clearly:

A resistor with e.g. 1GOhm resistance value supposed to have a Vcr of lets say -1000ppm/V. Then the value of resistance will change from 1GOhm to 0,9GOhm (=-10%), if you change the voltage from 25V to 125V (voltage difference of ΔU = 100V). Analog this holds true for the Tcr.

Various companies are measuring the Vcr at different conditions which is not always clearly stated in the datasheets. According to MIL-STD-202G, Method 309, the Vcr has to be calculated/measured as follows:

- R = resistance at maximum specified working voltage E

- E = maximum specified working voltage

- r = resistance at 10% of the maximum specified working voltage E

Exactly this kind of measurement and calculation of Vcr is not widely used, because of several practical reasons. For example, the maximum working voltage may be really high (10kV up to 100kV or more) and then you may not have the corresponding high voltage source and measurement instrument. And to avoid self-heating for small SMD components this MIL standard demands pulsed measurement which makes it even more complicated –

keep in mind the time constant at very high resistances. With respect to the voltage ratio (U2/U1 = 10, U2-U1 = 0,9*U2) this standard was adopted to a large extent.

The absolute value of the Vcr depends on the used paste material, the sintering conditions and the layout of the resistive path of the component in question. Generally speaking, you achieve usually a better Vcr if you increase the length of the resistive path (L/B ratio or number of squares). If you need a good Vcr, you should use a kind of meander design which in turn may also allow you to use a paste with lower square resistance.

As an example, you see a small part of our incoming test for one single resistive paste below. We test three different component sizes with different Length-to-Width ratios at different sintering temperatures and measure the Vcr between 10V and 100V.

Measurement of (low) Vcr

Measuring Vcr invokes some attention to peculiarities, which do not pop up at the measurement of Tcr:

- Number of securely steady digits/reading accuracy:

Because the Vcr plays an important role mainly at very high ohmic values, one has to pay attention be able to read enough valid digits from your measurement instrument without any digit hopping. Depending on your demands to discriminate between e.g.10ppm/V or 20ppm/V and your voltage swing you have to read 4 or 5 or more digits securely. This means the last digit must be steady and not randomly go up or down. This is very

demanding in an industrial environment at low voltages (e.g. 1V) and high R-values (e.g. 100GOhm corresponds to 10pA measurement current). - Measurement environment:

The measurement environment is very important because this mainly affects the noise, the wander and the shifts which you encounter during your measurement. This may limit the reliability of your significant digits (see point 1). Especially air humidity, airflows from AC or open doors, vibrations from machines and the effect onto cables and housing should be considered and – if possible – avoided. - Change of measurement range between the two voltages:

Totally different to the Tcr measurement it is very often necessary at the measurement of the Vcr to change the measurement range. This is due to the fact, that at Vcr measurement you really measure the current which changes almost according to the applied voltage. If you measure the Vcr between 1V and 10V the current through the resistor changes also with a factor of nearly ten. But the different measurement ranges have different accuracies and are sometimes not very good tuned to each other concerning linearity and offset. - The temperature coefficient itself/temperature variation:

At very low Vcr, high measurement voltage and small size you have to take care of selfheating of the device. Due to the temperature coefficient of the component, it may be possible that you will measure a Vcr which is not present or which is compensated or exaggerated by the Tcr. The same hold true for changes in temperature from outside. - Accuracy of measurement instruments:

Especially in the very high ohmic regime let’s say above 1GOhm you have to measure with electrometers which accuracies of current measurement are sometimes not as good as it may be necessary. Specifications of the current measurement in the range of 10pA or 100pA are often in the range of 1% or 0,5% relative to the national standard. One percent corresponds to 10 000ppm/V. Even if your voltage difference is 100V there are still

remaining 100ppm inaccuracy for one measurement point, if your instrument accuracy lays at the edge of its allowed range. This means that according to your instrument your Vcr may be very near zero but in reality, it is more around 50ppm/V. You can only improve this slightly by measuring with different instruments or by investing much more in new and better equipment. - Measurement time: Resistors with high values and low Vcr are often mechanically big and do have wires as electrical contacts. Due to this these resistors have relatively high intrinsic capacity C1. And there are external capacitances C2 due to cables, adapters, surrounding and so on. So it takes time to reach the final resistance value, because you should wait at least 5 times the electrical time constant τ = R*(C1 + C2). This may take several ten minutes.

The measurement of the Vcr involves all these challenging tasks and leads one to the point that the statements of Vcr in the range of 1ppm/V or below may be at least critical scrutinised. This deems to be unrealistic accurate at very high ohmic values and low voltage swings.

Applications Where you Have to Keep Vcr on Mind:

There are a lot of application where you need a high ohmic resistor and a low Vcr. Probably the most prominent example is the usage of such a resistor in a TIA amplifier configuration as a feedback resistor. If you would like to amplify tiny currents from a sensor and convert them to easy measurable voltages, you need a very high amplification. This is achieved with a very high feedback resistor.

But for this application you need a low Tcr and a low Vcr at low voltages. If you have e.g. a 1206 size resistor with a specified maximum working voltage of 400V – the measurement of the Vcr between 40V and 400 V makes no sense at all, because the resistor sees a voltage between let’s say 1V and 10V in the application. Because the voltage difference is small you may omit this albeit Vcr is higher at low voltages. If you do not want to omit this, you have to measure the Vcr at low voltages and use a correction curve/table within your TIA system.

About Author

Dr. Stephan Prucker, Dipl. Phys., Dr. rer. nat.

SRT Resistor Technology GmbH QMB, Leiter Produktion &Technologieentwicklung, Geschäftsführer

contact e-mail here