source: Department of Materials and Environmental Technology, Tallinn University of Technology, Tallinn, Estonia; ESA SPCD 2018 Symposium

EPCI e-symposium library article

Present work focuses on developing the method of producing carbon rich nanofibrous electrodes by electrospinning for supercapacitor electrodes. The influence of different polymer/carbon ratio to solution viscosity and conductivity were observed. Electrochemical behavior of produced electrodes was evaluated in triethylmethylammonium tetrafluoroborate (TEMABF4) in acetonitrile (ACN) electrolyte by cyclic voltammetry method. The effects of various contents of polymer/ carbons to capacitance and mechanical properties are discussed. Results of experimental work

showed that with electrospun fibrous mats in thickness below 20 μm, capacitance up to 121 F/g was achieved.

published by EPCI under approval of ESA SPCD 2018 organizing committee.

Title: FULLY ELECTROSPUN DURABLE ELECTRODE AND ELECTROCHEMICAL DOUBLE-LAYER CAPACITOR FOR HIGH FREQUENCY APPLICATIONS

Author(s): Siret Malmberg(1,2), Elvira Tarasova(1), Viktoria Vassiljeva(1), Illia Krasnou(1), Mati Arulepp(2), Andres Krumme(1).

Organisation(s): (1) Department of Materials and Environmental Technology, Tallinn University of Technology, Tallinn, Estonia.

(2) Skeleton Technologies OÜ, Estonia.

Symposium: ESA SPCD 2018

Reference: Materials and Processes 1.

ISBN: N/A

e-Sessions Applications: Aerospace

e-Sessions Scope Components: Capacitors

e-Sessions Topics: Technology, Materials

INTRODUCTION

Electrochemical capacitors are energy storage devices with long cycle life and fast charge-discharge capability [1]. Supercapacitors store energy using either ion adsorption (electrochemical double layer capacitors, EDLC) or fast surface redox reactions (pseudocapacitors). Traditional capacitor electrodes are produced in the form of film, activated carbon paste or carbon fabric. However, in recent years electrochemical capacitor electrodes have been also produced from electrospun nanofibers. Electrospinning as fiber forming process has found to be one of alternative methods to

produce durable supercapacitor electrodes [2].

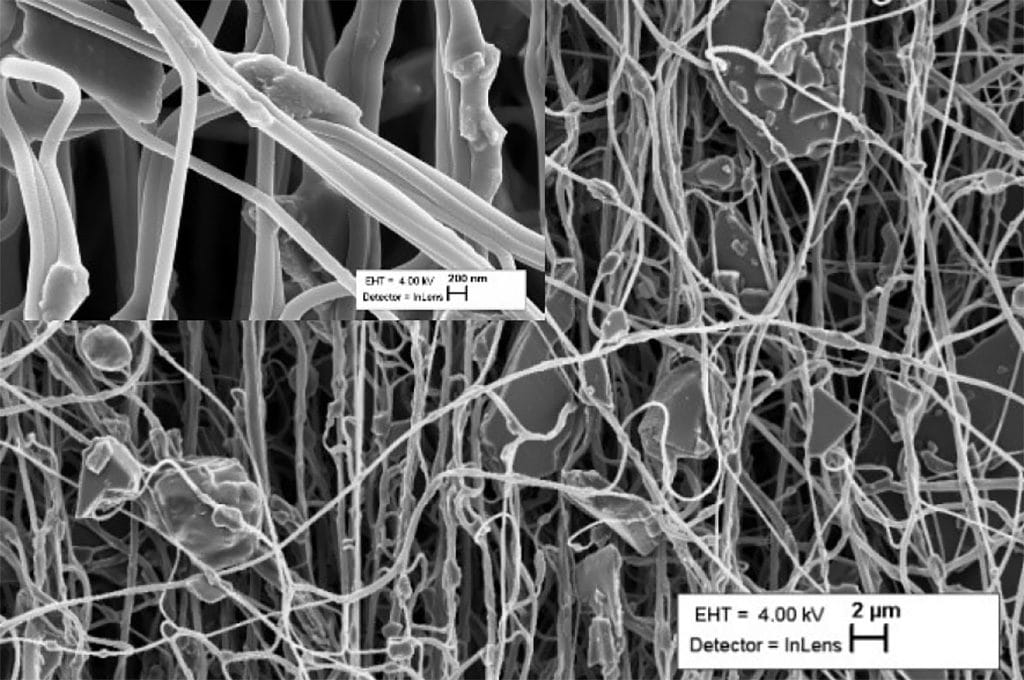

The advantage of the electrospinning method comes from the high specific surface area of the fibrous material, which is directly related to supercapacitor performance at higher frequencies. In addition, electrospun fibers have good mechanical properties including resistance to cyclic loading and vibrations [3]. Another advantage of the electrospinning is the inequality of the composition of fibers, which can be produced from the large variety of different polymers and polymer composites. Therefore, the goal of this study is to develop electrospun fibrous flexible EDLC electrodes, which are suitable for high frequency applications with stable capacitance under specific environmental conditions.

EXPERIMENTAL

First, to achieve the aim of the study the polyacrylonitrile (PAN, Mw 150 000 g/mol, by Sigma Aldrich) was chosen as a binder. For the solutions and dispersions preparations dimethylformamide (DMF, Sigma Aldrich) was used as a solvent and ionic liquid (IL), 1-ethyl-3-methylimidazoliumtetrfluoroborate (EMIMBF4) (produced by IoLiTec) as carbon dispersive and electric conductivity enhancing agents. The properties and electrospinnability of all solutions and dispersions have been studied. For developing the method of preparation of the carbide derived carbon (CDC) containing fibrous electrodes, titanium carbide derived carbon was used, with particle size 5 μm.

Used CDC was produced by Skeleton Technologies OÜ. As the initial particle size of CDC was too large, grinding process was applied to reduce their size down to ~0.5μm. Retsch PM 100 planetary ball mills was used to grind the carbon particles by zirconium oxide balls. Then, to electrospin fibrous electrodes from polymer/carbon dispersions, two dispersion preparation methods have been elaborated and tested. In both methods, the Node ultrasonic homogenizer Bandelin Sonoplus (Germany) was used with a 1 cm diameter nozzle to disperse the carbon particles in the solvent.

Finally, mechanical strength and electrochemical behavior was studied for electrospun membranes. The electrochemical evaluation was done by cyclic voltammetry (VMP3, EC-lab software) mostly. Mechanical testing and vibration tests of the membranes/electrodes were also conducted.

1. Evaluation of the properties of electrospinning solutions and dispersions

The flow curves of all the solutions and dispersions were measured to study their shear viscosity. The rheology measurements were conducted with the Physica MCR 501 rheometer (Anton Paar, Austria) using the cone and plate method in continuous rotation mode. The measuring cone CP25-2 with a diameter of 25 mm and 2° angle was used for the measurements and the shear viscosity was measured at shear rates from 0,01 to 100 s-1. The tests were conducted at room temperature. The electric conductivity was measured for all the prepared solutions and dispersions using a conductivity meter (Metler Toledo Seven Compact) at room temperature.

2. Electrospinning setup and conditions

Samples were electrospun at room temperature and humidity, at the voltage of 10 kV, the distance between spinneret and collector of 10 cm and the pumping rate of 0.2 ml/h. The membranes were electrospun to the drum collector with dimensions of 10 cm in diameter and 5 cm in width. As a spinneret the stainless steel needle with inner diameter of 0.1 mm was used, which connected to 1 ml plastic syringe.

3. Electrochemical evaluation of EDLC cell

The capacitance of electrospun electrodes was studied in EDLC test cell. Cellulose based ion-permeable separator paper Nippon Kodashi with thickness of 2*25 μm (TF44-25) was used in measuring EDLC cell. From electrospun mats, electrodes of size 2×3 cm and 3×4 cm were cut out. Each electrode was then pressed under flat plate pressing machine at 25 bars (per surface area 1.77 cm2) and 75°C. After that, electrodes were dried under vacuum at 110°C for 72 h to get rid of any excess moisture before assembling into the cell. To provide better electric connection with cell, double side carbon coated aluminum foil (Toyal foil with thickness 22 μm) was used as a collector. The assembled cell firstly was dried under vacuum at 110°C during 72 h and then filled with 1.8 M TEMABF4/ACN electrolyte.

The electrochemical properties of fully assembled cells were determined using cyclic voltammetry (two-electrode experiment). In cyclic voltammetry (CV), the current at the working electrode versus the applied voltage is plotted to give the cyclic voltammogram. The measuring of current was done using different sweep rates (1, 2, 5, 10 and 50mV/s). From the CV curves, the cell capacitance in Farads (F) was firstly calculated and next, specific capacitance in F/g per mass of active carbonous material has been calculated.

… read more at the full paper below…

CONCLUSION

In present study electrospun fibrous flexible EDLC electrodes have been developed. This material is suitable for higher frequency applications without significant loss of capacitance under specific environmental conditions. The developed flexible fibrous electrode PAN+ TiC/CB + EMIMBF4 showed the specific capacitance up to 121 F/g with CDC and CB ratio 80/ 20 respectively.

Produced electrode showed good mechanical properties as specific stress for fibrous electrodes were almost 20 times higher compared to the roll casted mats. Furthermore, fibrous electrodes can be easily folded or twisted without inducing any visual damage. This combination of flexibility, folding and twisting possibility is desirable for supercapacitor electrodes.

Developed fibrous electrodes were tested in EDLC cells under vibration, the specific capacitance dropped after vigorous vibration by only 5%, which indicates that electrospun electrodes can withstand rather high loads (vibrations) with minimal lose in energy.

Acknowledgements

The European Space Agency, ESA contract number 4000119258/16/NL/CBi “Fully electrospun durable electrode and electrochemical double-layer capacitor for high frequency applications”.

References

[1] Yonggang Wang , Yanfang Song and Yongyao Xia, Electrochemical capacitors: mechanism, materials, systems, characterization and applications, Chem. Soc. Rev., 2016, 45, 5925-5950

[2] Mao, Xianwen, T. Hatton, and Gregory Rutledge. “A Review of Electrospun Carbon Fibers as Electrode Materials for Energy Storage.” COC 17, no. 13 (June 1, 2013): 1390–1401

[3] Selina Liu, Matt Kok, Yongwook Kim, John L. Barton, Fikil R. Brushett and Jeff Gostick, Evaluation of Electrospun Fibrous Mats Targeted for Use as Flow Battery Electrodes, J. Electrochem. Soc. 2017 volume 164, issue 9, 2038-2048

[4] G. Chatel and D. R. MacFarlane, Ionic liquids and ultrasound in combination: synergies and challenges, Chem. Soc. Rev., 2014, 43, 8132

read the full technical paper in pdf here:

and presentation here: