This paper on novel high energy graphene material for supercapacitors was presented by Tomas Zednicek, EPCI European Passive Components Institute during the 5th Space Passive Component Days (SPCD), an International Symposium held from October 15th to 18th, 2024, at ESA/ESTEC in Noordwijk, the Netherlands. Published under permission from ESA SPCD organizers.

A novel nitrogen-doped graphene material (SC-GN3) with a high mass density of 2.8 g/cm3 and diamond-like carbon-carbon bonds has been developed.

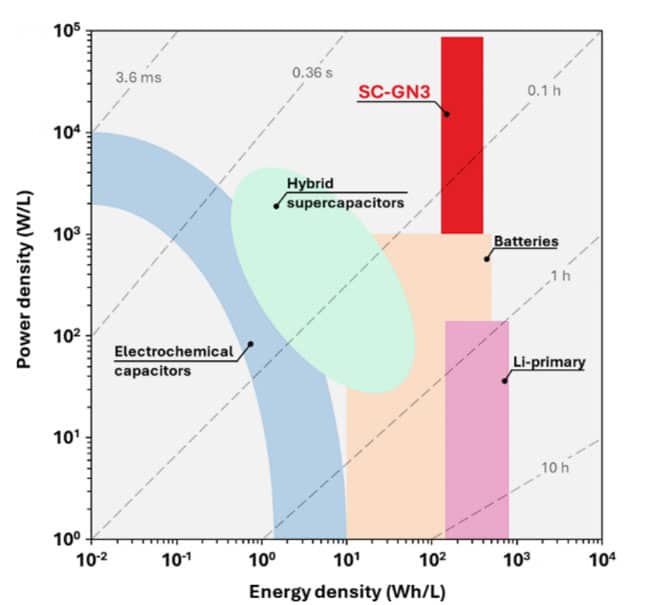

This material, when used as an active electrode in supercapacitors, demonstrates unprecedented energy densities of up to 200 Wh/L at a power density of 2.6 kW/L.

The researchers are now working on commercialization-ready prototypes of wound and pouch supercapacitors, aiming to meet industry standards for energy density, power density, and environmental life tests.

The development of a commercial supercapacitor using SC-GN3 active electrode material involves validating lab-scale processes for mass manufacturing. This includes ensuring compatibility between SC-GN3 and manufacturing processes, as well as optimizing electrolyte and separator selection for improved performance and cost-effectiveness. The first prototype, a wound supercapacitor with 1500F and 2.85V, was successfully manufactured using SC-GN3-coated aluminum foil electrodes and a standard aluminum can assembly.

The SC-GN3 supercapacitor technology, utilizing nitrogen-doped graphene, shows promise in enhancing energy and power densities. Initial prototypes, both wound and pouch, demonstrate competitive performance, with the wound prototype achieving an energy density of 14Wh/L and the pouch prototype projected to reach 10.8Wh/L. The next steps involve optimizing electrode designs and ensuring a sustainable supply chain for the fluorographene precursor.

Next prototypes of supercapacitors with graphene material are aimed to reach a record-high energy density of 55Wh/L and power density of over 30kW/kg. The prototype reliability testing starting in 2025.

Target Supercapacitor Parameters

The market analyses and other inputs defined target specification requirements as follows:

Tier 1. Requirements (Must Have) Match with Industry Standard Supercapacitor Specifications:

- Energy Density exceeding 16Wh/L

- Power Density exceeding 29kW/kg

- Voltage: >2.85V

- Temperature Range: Wound cell: -40°C to +65°C / +85°C with derating, Pouch cell: -40°C to +70°C

- Environmental Life Tests: as per the industry standards

Tier 2. Requirements (Nice to Have)

- Improved Temperature Range: 40°C to +85°C

- Higher Voltage: >3V

- Low Self-Discharge /w Temperature Characteristics

- Reflow Capability

- Flexible Design (Wearables)

- Bio-Waste Material Use / Sustainability even at Lower ED/PD

Read the full paper: