Researchers from China published results of their research Additive manufacturing of Mn-Zn ferrite planar inductors with CaO–SiO2 modified slurries: A magneto-thermal optimization approach published by Materials & Design Journal.

Introduction

The advancement of soft magnetic materials, particularly Mn-Zn ferrite powders, plays a pivotal role in enhancing the performance of integrated planar inductors.

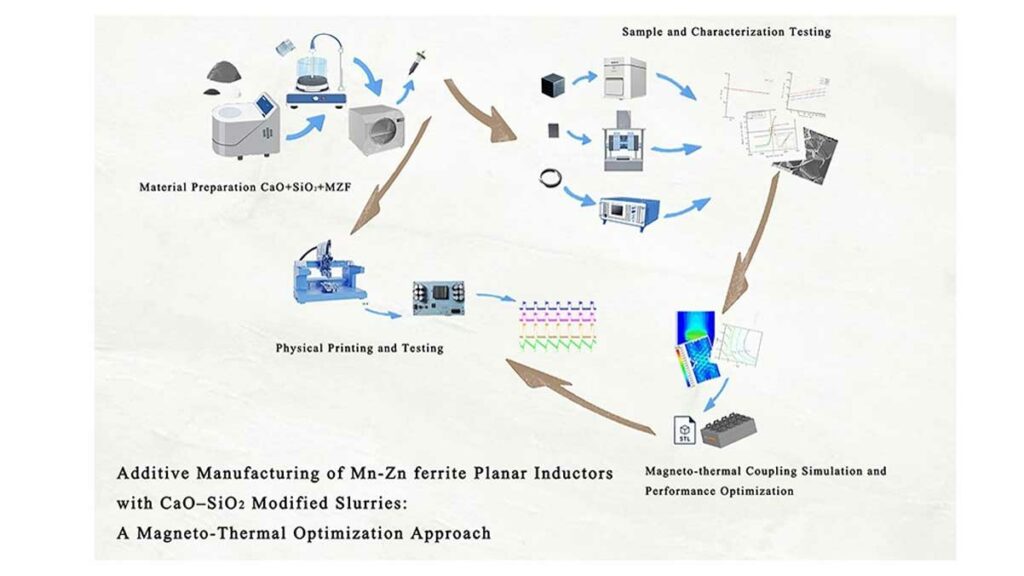

Traditional fabrication methods, such as compression molding, often limit the design flexibility needed for customized magnetic cores. This article explores the innovative application of a multi-nozzle slurry-based printing technique to overcome these constraints, aiming to optimize both magnetic and thermal properties through additive manufacturing.

Key Points

- Limitations of Traditional Methods: Compression molding restricts design adaptability in soft magnetic cores.

- Innovative Printing Technique: Utilization of a multi-nozzle slurry-based printing process for Mn-Zn ferrite powders.

- Additives for Optimization: Introduction of CaO (0.5 wt%) and SiO2 (0.05 wt%) to improve grain boundary phases.

- Enhanced Properties: Achieving optimal microstructure, electrical resistivity, and magnetic performance through sintering at 1200°C.

- Experimental Validation: Fabrication and testing of a prototype confirming magneto-thermal optimization capabilities.

Extended Summary

Traditional fabrication techniques for Mn-Zn ferrite powders, such as compression molding, have long been the standard in producing soft magnetic cores. However, these methods inherently limit the potential for custom designs, which are increasingly in demand for advanced electronic applications. Recognizing this limitation, the study introduces a groundbreaking multi-nozzle slurry-based printing technique tailored for commercially available Mn-Zn ferrite powders.

The innovation doesn’t stop at the printing technique. To further refine the material properties, small quantities of sintering additives—CaO (0.5 wt%) and SiO2 (0.05 wt%)—are incorporated. These additives play a crucial role in modifying grain boundary phases, which in turn enhances electrical resistivity and reduces porosity. This meticulous adjustment leads to superior microstructural attributes and magnetic properties.

Achieving the desired material characteristics requires precise thermal management. The study identifies 1200°C as the optimal sintering temperature, complemented by tailored thermal treatment conditions. This specific process results in enhanced initial permeability, improved saturation magnetization, and reduced core loss, key parameters critical for magnetic performance.

Building on these insights, the researchers have designed and fabricated a modified Mn-Zn ferrite core utilizing the composite additive manufacturing method. This new core not only integrates advanced thermal management features but also exhibits superior magnetic performance. A physical prototype of the composite inductor was produced to validate these findings experimentally. The prototype’s performance confirmed the feasibility and effectiveness of this approach in achieving magneto-thermal optimization.

Conclusion

This study showcases the potential of additive manufacturing, specifically a multi-nozzle slurry-based printing technique, in revolutionizing the fabrication of Mn-Zn ferrite magnetic cores. By incorporating strategic sintering additives and optimizing thermal treatments, the research successfully enhances both magnetic and thermal properties. The fabrication and validation of a physical prototype underscore the practical applicability of this innovative process, paving the way for more flexible and efficient designs in integrated planar inductors.

Read the full paper:

Wenjie Zhang, Qian Zhu, Huoying Tan, Jiquan Yang, Jianping Shi,

Additive manufacturing of Mn-Zn ferrite planar inductors with CaO–SiO2 modified slurries: A magneto-thermal optimization approach,

Materials & Design, Volume 257, 2025, 114438,ISSN 0264-1275,

https://doi.org/10.1016/j.matdes.2025.114438.