The article explains construction, application and features of film and foil organic dielectric capacitors.

Key Takeaway

- Film and foil organic dielectric capacitors are essential components in high-voltage and high-power applications due to their low loss factor, high dielectric strength, and long operational life.

- Different dielectric materials such as polyester (PET), polypropylene (PP), polyphenylene sulfide (PPS), and PTFE offer unique performance characteristics, making them suitable for applications ranging from automotive DC links to precision timing circuits.

- Key applications: DC link (EV/renewables), AC motor start, EMI suppression, X/Y safety capacitors.

- Self‑healing: Local breakdown clears defects and isolates faults, improving reliability.

- Reliability boosts: Optimized windings, heat‑treatment, impregnation, encapsulation, and hermetic sealing.

Film capacitors are essential electrostatic capacitors suitable for medium, higher voltage and higher current circuits. Unlike most other dielectric systems, film capacitors feature low loss factor at very low temperature.

- Paper MP capacitors

- Polyester PET /KT/MKT capacitors

- Polypropylene PP /KP/MKP capacitors

- Polycarbonate PC /KC/MKC capacitors

- Polystyrene PS, Polyphenylene sulfide PPS and other plastic film capacitors Teflon PTFE / Polysulfone PSU

Dielectric constant is not big, but they feature very high dielectric strength. In combination with long life and self-healing aging capabilities it makes them ideal choice for high voltage, high power systems. While we focus on the most common dielectric types there is a wide list of organic dielectric materials with different features. Overview can be seen in the article: What is a Dielectric Constant of Plastic Materials ?

Due to its high dielectric strength, film capacitors are often used in high-power, high-voltage applications including modern resonant power converters in renewable energy or EV charging circuits. Its ripple current capabilities can be further improved by cooling – learn more in the video here: Water Cooled Polypropylene Capacitors

Introduction & Benchmarking

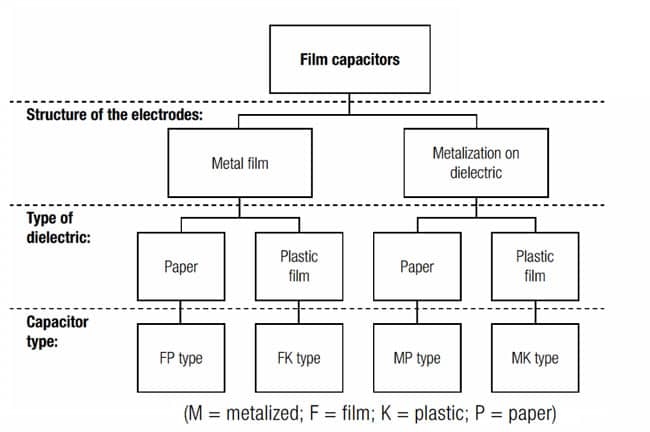

There are more types of film capacitors that differs by structure of the electrodes (if metal film electrode is used or metallization is already deposited on the electrodes) and type of dielectric as illustrated in the Figure below.

The most common dielectric materials used in the construction of plastic film capacitors are polypropylene and polyester. Other dielectrics used in the construction of film capacitors include polycarbonate, polystyrene, polytetrafluoroethylene (PTFE), polyethylene naphthalate (PEN), polyphenylene sulphide (PPS), polyimide, and paper as discussed in next chapters in more details. The following table shows common codes for the main dielectric types:

Polyester (PET)

Polyester has a high dielectric constant compared to polypropylene, and is one of the most widely used dielectric materials. This high dielectric constant allows construction of capacitors with small physical sizes. Polyester capacitors, also known as mylar capacitors, have good self-healing properties and are relatively cheap.

At high temperatures, polyester capacitors dissipate more power. This characteristic makes these capacitors unsuitable for high frequency and high current AC applications. Furthermore, polyester exhibits a significant capacitance change, up to 5%, as temperature approaches low or high-temperature limits. Due to this characteristic, polyester is an unsuitable material for constructing precision capacitors. Polyester capacitors are mostly used in general purpose board level applications such as blocking, bypassing, decoupling, and some noise suppression circuits.

Polypropylene (PP)

Polypropylene is commonly used in the construction of capacitors for high frequency AC applications. This dielectric material has a low dissipation factor, high breakdown strength, low dielectric absorption, high insulation resistance, and is readily available. These properties make polypropylene a dielectric material of choice for a wide range of applications including snubber circuits, high frequency AC systems, high voltage DC & AC systems, and high current DC applications.

Polypropylene capacitors can operate over a wide temperature range. Unlike polyester capacitors, the capacitance of a polypropylene capacitor decreases with temperature. Due to its temperature characteristics, polypropylene capacitors are commonly used to complement polyester capacitors. This is achieved by connecting a polyester capacitor and a polypropylene capacitor in parallel.

Despite its impressive properties, polypropylene has a lower dielectric constant than polyester. In addition, this material is not available in thin-gauge films. Compared to polyester, polypropylene is more expensive and is not a suitable material when physical size of a component is a key consideration.

Polyphenylene sulphide (PPS)

Polyphenylene sulphide has excellent temperature characteristics and is commonly used for constructing precision capacitors. The capacitance of these capacitors does not vary significantly with changes in temperature. PPS capacitors are commonly used to replace polycarbonate capacitors in electronic circuits. The dielectric constants of these two materials are similar, and both have high breakdown strength.

Polytetrafluoroethylene (PTFE)

PTFE capacitors, also known as Teflon capacitors, are low loss capacitors that offer excellent stability. PTFE has a relatively low dielectric constant, around 2.1, and it is, therefore, unsuitable for constructing components with small footprints. Teflon capacitors are suitable for high temperature applications and can be used in systems that expose components to temperatures of up to 200oC. PTFE capacitors have low capacitance values and are relatively expensive.

Polystyrene (PS)

Polystyrene capacitors exhibit extremely low loss and high capacitance stability over temperature, typically down to ±1% 0ver the range -55°C to +85°C. It’s low dielectric constant of 2.1 makes in suitable for low capacitance, high stability applications such as timing circuits.

Polyimide (Kapton)

Polyimide has a high dielectric constant, around 3.4, and it is commonly used for constructing components for high temperature applications. Kapton capacitors can be used in systems that can expose components to temperatures of up to 250oC. Metallized polyimide capacitors have poor self-healing characteristics.

Polycarbonate (PC)

Polycarbonate has an average dielectric constant, around 2.7, and it is commonly used in the construction of capacitors for high temperature applications. Polycarbonate capacitors are low loss components that have good electrical characteristics over a wide temperature range. Polycarbonate capacitors were widely used in military applications. However, polycarbonate film has limited availability, and is not recommended for new designs.

The table below summarises some characteristics of common plastic film dielectrics.

Applications & Designs

There are various forms of film capacitors on market from SMD chip style up to high power high voltage types:

SMD Stacked Chip

0.01uF – 15uF

30 – 400V

up to 125°C

Medium Power

High Power

Some typical examples of film capacitor applications:

- DC link in automotive or renewable energy generators

- AC motor and light start

- Medical defibrilators

- Railway systems

- Defence and space hardware

- Energy distribution and power correction

- X and Y safety capacitors

- EMI noise suppression

Key Attributes of Film Capacitors:

Polar Plastics Vs Non-polar Plastic Dielectrics

Dielectric properties of a polymer largely depend upon their structure. The structure determines whether a polymer is polar or non-polar and this in turn decided the electrical properties of the polymer.

- In polar polymers (PMMA, PVC, Nylon, PC etc.), dipoles are created due to imbalance in the distribution of electrons. These dipoles tend to align in the presence of electric field. Hence, this creates dipole polarization of the material making these materials only moderately good as insulators.

- While non-polar polymers (PTFE, PP, PE, PS) have symmetrical molecules and are truly covalent. There are no polar dipoles present in them and hence in presence of electric field does not align the dipoles. However, slight electron polarization occurs due to the movement of electrons in the direction of electric field, which is effectively instantaneous. These polymers have high resistivities and low dielectric constant.

Polar plastics have a tendency to absorb moisture from the atmosphere. Presence of moisture raises the dielectric constant and lowers the resistivity. With rise in temperature, there is faster movement of polymer chains and fast alignment of dipoles. This invariably raises the dielectric constant values for polar plastics.

Non-polar plastics are not affected by moisture and rise in temperature. Dielectric constant of various plastic materials can be found in the post linked in material folder of this lesson.

PET and PP totally dominate the film capacitor dielectric market. PP is a small and simple molecule. PET is „heavier” but also provides a stronger and higher tensile strength film that con be bi-axially oriented into very thin films.

Self-healing of Film Capacitors

Dielectrics always have weak spots or defects and thinner zones which are more sensitive to breakdowns than the ordinary material. A breakdown, i.e. a short circuit through the dielectric, leads to local energy generation which transforms the material in the breakthrough canal into a plasma and vaporizes the thin metallization around the breakthrough hole. Around this hole with a diameter of 5…100 μm (0.2…4 mils) there is created a metal-free insulation area approximately 0.1 to 3 mm (4 to 120 mils) in diameter. The instantaneous short circuit thus is turned into an open circuit. The phenomenon is called self-healing (Figure 9). The condition for self-healing is a certain minimum energy estimated to be at least 10 μJ. Small part capacitances or low working voltages, therefore, may lead to a lack of self-healing if a breakthrough nevertheless should occur in a weak spot, e.g. under extreme heat when the dielectric has grown weaker.

As indicated in Figure 9. the self-healing energy creates a plasma. Its temperature and pressure are extremely high but with short duration. The gas pressure developed around the breakthrough site propagates and separates the adjacent dielectric layers to an extent while the decomposition products are spread over the surrounding metallization and plasma pressure and temperature drop. The whole series of events for typical energies occurs within 0.01 to 1 μs. Electrically, the event manifests itself in an abrupt voltage drop which is restored as a charging curve, usually within 100 μs. The time constant is determined by RC product of the immediate external circuit. It’s a rare occasion that the whole existing energy is used for the self-healing. The voltage drop usually don’t get any further than a few to some tens % of the total load voltage in metallized plastic film capacitors and 10 mV…1 V in MPs (metallized paper) and lacquer film capacitors ( cellulose acetate).

The self-healing design permits lower safety margins between the breakdown voltage and the rated. A short circuit doesn’t have to be avoided at any price. The ratio of breakdown voltage to rated voltage can be decreased from (10…15):1 to (3…6):1 which reduces the thickness of the dielectric foils correspondingly.

Resulting effects of a self-healing

During self-healing the polymeric dielectric is decomposed. Carbon-rich compounds generate amorphous carbon which will be deposited on cavity walls and, unfortunately, also on the insulated burned off surfaces around the breakthrough hole and its canal walls (Figure 10.).

Compounds very rich in carbon, such as polystyrene, generate so much carbon that they are impossible to use in a customarily metallized design. The carbon deposits destroy the IR after a self-healing.

Other materials have a varying degree of carbon generation (Table 1). That information, however, must be combined with information on the clearing chemistry of the materials. Best is PP followed by PET and the poorer PPS and PEN.

Even if the deposited graphite does not destroy the IR, sometimes graphite particles under the influence of weak field strengths line up to form conductive strings with an unstable resistance in the range of some hundreds to some hundred kΩ. In practice this is a short circuit. If the voltage is raised or the circuit impedance doesn’t limit the current the conductive carbon string is burnt off. We never experience the phenomenon in practice because the required energy is much smaller than that of a self-healing. If the application, however, is critical and works in high impedance circuits at temporarily low field strengths the short circuit doesn’t disappear. Hence, certain dielectrics in film capacitors should be avoided if we don’t purchase capacitors after they have passed extensive burn-in and powered thermal cycling testing.

The risk of this type of carbon deposits increases with the internal pressure of the winding. Precision capacitors are, for example, wound on a core with a relatively high tensile stress which gives a dense and mechanically stable winding. The following figure shows schematically the approximate internal pressure distribution in some different winding types.

- a) winding on a core,

- b) winding without a core,

- c) flattened winding,

- d) stacked-type.

In severe cases the winding pressure may approach 100 bars (» 1450 psi). But the internal pressure prevents the plasma from expanding with the consequence that the carbon deposit is concentrated at the immediate breakdown site. This in turn increases the risk of ”carbon string” short circuits. Furthermore, the risk of damage to neighboring dielectric layers increases if the developed energy corresponds to high working voltages (Figure 12.).

In the most severe case self-healing under these conditions results in a thermal run-away where the capacitor is destroyed and may burn.

Reliability and Robustness Improvements

Flattened windings

Windings not wound on a core will become loose in its center where the removed shaft has been but will achieve a relatively high pressure further on into the winding. If such windings are flat the part will have two advantages. First the center will become more rigid. Second the long sides of the flat cross-section will facilitate expansion if there should be any self-healing (Figure 11).

Heat treatment / shrinking

The body stiffening which is created by metal foil electrodes disappears with the use of metallized foil electrodes. The winding becomes looser and is more readily subject to the formation of creases and cavities. If it is not impregnated the risk of corona increases in alternating voltage applications. To some extent, however, these drawbacks can be eliminated in plastic film capacitors, metallized as well as foil electrode types. The used plastic foils are cold-rolled both lengthwise and to some extent also in breadth in order to achieve a thinner foil. New technologies giving better film properties use a simultaneous biaxial stretching to get the wanted film thickness. Anyhow, the molecules are ”frozen” in a compulsory position. But at a certain elevated temperature they start leaving this position. At a continuous temperature rise the process eventually ends up with all molecules retaining their initial position completely. This occurs through baking the winding at certain elevated temperature. The winding shrinks slightly and becomes harder. But the temperature rise must be limited. Otherwise the shrinking will continue which in turn may cause deteriorated joints between end spray and metallization, increasing losses (ESR) and loss of capacitance. The development of surface mount (SM) types that can endure soldering heat therefore has encountered many problems. Two principal approaches are distinguishable. One is utilizing the encapsulation as a heat shield, the other erases the molecular memory of their position before the cold-rolled stretching.

Which approach is preferable may depend on utilized soldering process. Independent of line, type and manufacture it’s advisable to evaluate the quality of parts before and after soldering. According to the authors opinion the best way is by measuring the ESR at the resonance frequency.

Impregnation / Voltage distribution

Capacitors that must operate at voltages where corona effects start to appear must not contain gas or air filled cavities. The electric field strength in the void was several times higher than in the homogeneous dielectric. Hence, cavities which can’t be avoided through good manufacturing technology have to be eliminated in some way or another.

One way of elimination of cavities is with impregnation (an absolute necessity if paper windings are used). Mineral and silicone oils, waxes and epoxy are the most common impregnants. Currently, as they fill internal cavities and increases the tension stability they also influence the dielectric constant slightly.

The impregnation is performed in vacuum in order to fill all cavities completely. It’s not that easy – one could do with various means available in order to succeed perfectly – and here the liquid impregnation agents are advantageous. However, mineral oils should not be used with metallized foil capacitors because the self-healing action decomposes and contaminates the oil whose insulation resistance (IR) then decreases. Instead, some vegetable oils are used.

Even if we have succeeded perfectly with the impregnation and kept the electric field strength in the dielectric within permitted limits by increasing foil thickness, there are limits for the operating voltage. Along the edges of the electrodes field strengths are developed that at a certain magnitude cause a flash-over. Thus one is forced to distribute the voltage over several capacitor elements. For non-impregnated capacitors this construction solution must be engaged even sooner because of the corona risk. The principle is shown in Figure 13. where the elements are connected in series through a common ”free-standing” foil. The electrodes consist of real metal foils or one or double sided metallized plastic films or a combination of these types.

In principle, with this type of connection, we exchange parallel electrodes for series connected ones. While the voltage capability is doubled in the same capacitor volume the capacitance is reduced to one quarter.

Such design with “floated” electrodes is also used by ceramic capacitor safe design to suppress critical crack issues – see figure on right.

Hermetic encapsulation

Sometimes components need encapsulations that are moisture barriers. Then, no lacquer or polymeric seal, however good, will do. Humidity will diffuse through such materials with sufficient time. In this application only certain inorganic materials as glass, metal and solder will do. A common combination is metal cans with glass and solder seals around the terminal leads. We shall not enter upon all those problems one then has to consider in order to match glass types, thicknesses, diameters and alloys in the feed-throughs etc. and thus bring about components which will withstand also temperature changes. One failure mode, however, we shall consider. It occasionally occurs with hermetic components having a solder seal around the terminal leads. Figure 14. represent such a typical component with metal bushings and solder seals.

The solder sealing usually is made with the can in a perpendicular position which may result in a risk of melted solder dripping into the can, especially if the other feed-through is not yet sealed so it can create a ”back-pressure” from the gas inclusion which will prevent the solder from dripping. Later these solder beads or droplets may cause short circuits, especially in components with insertion tabs. In addition the internal gas pressure in the can may cause failures. If the sealing process conveys too much heat before the solder has solidified there is a risk that the pressure may open a tiny duct in the solder seal (a so called blow-out). Such an internal gas pressure may be produced also during the soldering process. If the solderability is poor a prolonged soldering process may cause conditions for a blow-out. This failure mechanism has been observed in solid tantalum capacitors.

Hermetic components with solder seals often comply with US and other MIL standards. Even if such components meet these MIL spec standards it must not be assumed that there are no loose solder beads inside the components. Such a quality level is guaranteed to a degree if real-time or micro-focus X-ray control is included in the manufacture inspection.

Epoxy sealed casings

It is usual to mold epoxy around components in metal cans or plastic casings. It is then important both that the box compound has been degassed first and that the filling operation takes place in a low pressure chamber so that the epoxy really penetrates into and surrounds the body and prevents forming of cavities and gas bubbles. Otherwise there will be places where diffusing humidity can condense if there is a sufficient decrease in temperature and cause problems. The risk is especially large when a cylindrical metal can is sealed from one end with epoxy. We know of one instance where a component style that had performed very well in a 56 day humidity test as specified in IEC 68. A 48°C freon washing and a subsequent rinse in distilled water of room temperature created such great temperature differences between the metal can and epoxy molding that the adhesion yielded. A slit opened along the metal wall and in those unfortunate cases where cavities occurred in the bottom of the can – Figure 15. – there the negative pressure in the cavity sucked in washing water that hit the exposed porous spray metal. Its capillary forces then transferred the water to the metallized electrodes and thus created a perfect electrolytic cell. Within a few hours electrolysis consumed most of the metallizing.

This same type of capacitance decrease has been observed also in metallized plastic film capacitors with radial leads in plastic casings. In a batch with an anomalous epoxy filling there were deep cracks down to occurring cavities localized against the end spray metal on the winding. Washing water mixed with flux then was sucked into the cavities, resulting in the same failure mechanism.

Four terminals

Assume now that a transient enters the circuit shown in Figure 16. Because the conventional lead mount decoupling capacitor has a certain inductance in the leads – approximately 1nH/mm lead length – the entrance is blocked for the transient that proceeds further towards the load.

In order to remedy the problem so called four terminal components are used, where both the signal and the transient are forced towards the capacitor electrodes (Figure 17). We can see also the similar princip in three terminal devices where, one termination is conventional and the other is split into two.

Note that the more and more common chip components in principle have the same type of noise suppressing termination as that of the four terminals.

Flammability

Components which run the risk of meeting with overvoltages that can lead to short-circuits, especially so called X and Y capacitors, they must be able to withstand certain flammability tests without being set on fire or burn. One distinguishes between active and passive flammability.

With passive flammability is understood the property of a component to continue burning after external ignition, i.e. ignition caused by energy applied from the outside of the component. Reference IEC 695-2-2.

With active flammability is understood a spontaneous ignition without external ignition.

Passive flammability can be brought about by self-extinguishing materials in casings and impregnation. Above all the resin impregnated metallized paper capacitor(MP) has a clear advantage over the metallized plastic film capacitors.

Film Capacitor Construction and Manufacturing

Film capacitors can be produced as wound or stacked foil capacitors types depending to the final application requirements and features – see figures bellow. Minimum rated voltage of film capacitors is mostly limited by its mechanical strength to withstand the winding process and it starts typically from >3um per layer corresponding to ~30V, thus it is not direct competition to low voltage SMD other capacitor technologies.

The exception is multilayer SMD stacked capacitor Rubycon PMLCAP(R) that employs electron beam curing resin as the dielectric material and vacuum deposition polymerization technology as manufacturing method that enable dielectric thickness to be less than 1um allowing minimum voltage (and high capacitance) from 10/16V and offer alternative to MLCC class I capacitors even at low voltage applications.

Construction

Manufacturing Process

The following example describes a typical manufacturing process flow for wound metallized plastic film capacitors.

- Film stretching and metallization — To increase the capacitance value of the capacitor, the plastic film is drawn using a special extrusion process of bi-axial stretching in longitudinal and transverse directions, as thin as is technically possible and as allowed by the desired breakdown voltage. The thickness of these films can be as little as 0.6 μm. In a suitable evaporation system and under high vacuum conditions (about 1015 to 1019 molecules of air per cubic meter) the plastic film is metallized with aluminum or zinc. It is then wound onto a so-called “mother roll” with a width of about 1 meter.

- Film slitting — Next, the mother rolls are slit into small strips of plastic film in the required width according to the size of the capacitors being manufactured.

- Winding — Two films are rolled together into a cylindrical winding. The two metallized films that make up a capacitor are wound slightly offset from each other, so that by the arrangement of the electrodes one edge of the metallization on each end of the winding extends out laterally.

- Flattening — The winding is usually flattened into an oval shape by applying mechanical pressure. Because the cost of a printed circuit board is calculated per square millimeter, a smaller capacitor footprint reduces the overall cost of the circuit.

- Application of metallic contact layer (“schoopage”) — The projecting end electrodes are covered with a liquefied contact metal such as (tin, zinc or aluminum), which is sprayed with compressed air on both lateral ends of the winding. This metallizing process is named schoopage after Swiss engineer Max Schoop, who invented a combustion spray application for tin and lead.

- Healing — The windings which are now electrically connected by the schoopage have to be “healed”. This is done by applying a precisely calibrated voltage across the electrodes of the winding so that any existing defects will be “burned away” (see also “self-healing” below).

- Impregnation — For increased protection of the capacitor against environmental influences, especially moisture, the winding is impregnated with an insulating fluid, such as silicone oil.

- Attachment of terminals — The terminals of the capacitor are soldered or welded on the end metal contact layers of the schoopage.

- Coating — After attaching the terminals, the capacitor body is potted into an external casing, or is dipped into a protective coating. For lowest production costs some film capacitors can be used “naked”, without further coating of the winding.

- Electrical final test — All capacitors (100%) should be tested for the most important electrical parameters, capacitance (C), dissipation factor (tan δ) and impedance (Z).

Paper Capacitors

Under this headline we deal mainly with pure paper dielectrics. At the same time we ought to say that combinations of paper and plastic, i.e. mixed dielectrics, are rather common.

The “pure” paper capacitors (MP) are not anymore in often use, but it is good to get familiar with the technology and explain some principles. Metallized paper MP and plastic film MK (MKP and MKT) technologies are still used today as EMI noise suppression capacitors.

Plastic film MKT and MKP electrostatic capacitors are offering higher capacitance values in smaller case sizes compared to MP capacitors. However, thanks to the good oxidation behaviour of the paper dielectric, MP paper capacitors have outstanding self-healing properties and reliability even with high energy pulses.

Paper / foil

The history of the commercial capacitor started with paper foil dielectrics and electrodes of aluminum foils. Because paper is porous it has to be impregnated in order to prevent corona effects and flash-overs. It is done by use of melted wax or different kinds of oils, among other things mineral and silicone oils. The oils increase the tensional stability but decrease to a certain extent the εr. Fibrous paper has an εr ≈ 6.6 and the mineral oil ≈ 2.3 which gives the impregnated winding an εr varying between 3.1 and 4.5. The differences depend above all on the winding pressure produced by the tensile force during winding.

Formerly at least two impregnated paper foils were used because of the character of the paper. Today mixed dielectrics are used frequently where the paper is combined with plastic foils, usually polyester (PET) or polypropylene.

Because the summary tables following each presented material type don’t deal with the impregnation agents and mixed dielectrics separately we mention some of their characteristics in following Table 1.

Oil impregnated paper is, above all, used in power, mains and in certain feed-through capacitors. In this handbook we restrict ourselves to those smaller types which belong to the electronic components. They constitute an fading component category that more and more is replaced with plastic dielectrics.

In common mains and feed-through capacitors intended for consumer purposes the casings contain only a faint amount of oil. Most of it exist in the paper foils. The impregnation is carried out in vacuum on the finished winding after that the paper first has been dried carefully in an oven.

MP (metallized paper)

The first metallized film capacitor was built with metallized paper. The MP foil looks in principle like the one in Figure 18.

As impregnation agents solid substances like epoxy is predominant but vegetable oils may occur in certain types. The impregnation also protects the zinc metallization against aqueous corrosion and oxidation. Because the paper is porous and in certain points may contain some impurities or weaknesses one must in professional applications use designs with at least two layers of paper foils. The risk that a weak spot in one foil shall land opposite another one in the next layer is minimized. In stead of an extra paper foil nowadays mixed dielectrics are more and more frequently used with a polyester or polypropylene film together with the metallized paper foil. Also occurring are variants with a metallized plastic film and an impregnated paper foil.

The genuine MP capacitor once was falling out of use but concurrently with experiences from the plastic films it has witnessed a well-motivated renaissance. Above all it has to do with the need for transient protecting capacitors in mains applications. According to Table C2-1 the carbon deposit from self-healings produced during manufacture – so called clearings – are uniquely low for cellulose materials at the same time as the necessary energy release stops at completely harmless levels (ΔV ≈ -10 mV… -1 V).

Besides the MP capacitor has another advantage at pulse applications. Pulses mean steep voltage rise times and high charge and discharge currents. The usual zinc metallization together with an end spray metal consisting of a zinc compound (shooping metal) gives just that low ESR in the contact interface that is necessary for avoiding a local heating. Repetitive courses of pulse events may on the other hand create internal heating because of the dielectric losses. If the capacitor is used as an energy storing pulse transmitter part of the energy will be lost in the dielectric loss resistance Rd. The voltage Vc of the charged capacitor will at the discharge be voltage divided in Vd and VL (Figure 19.).

Temperature and frequency dependencies

Following diagrams show some typical graphs for the temperature and frequency dependence of paper capacitors.

In Figure 25., the impedance curve turns down in a sharp point around the resonance frequency. In low-loss components like film capacitors the decreasing capacitive reactance curve reach areas around the resonance frequency before it get to the limiting ESR contribution. Here the reactance drops even faster than according to the initial curve because of the counteracting inductive reactance.

The tip of the impedance curve in Figure 16. is in a larger magnification not so sharp that is indicated in the diagram.

(In capacitors with rather high losses as, for example, electrolytics the reactance curves reach the ESR contribution at frequencies far away from the resonance frequency. Here produces the dipole dependent capacitance decrease a deviation upwards from the initial reactance curve).

Failure modes

Penetrating moisture represents the greatest threat against paper capacitors because the paper absorbs humidity that in turn affects the IR and damages the dielectric. In foil capacitors internal, freely suspended terminal wires run the risk of vibrating to disruption.

Survey table

Metallized and foil capacitor specification general comparison is shown in Table 2. below.

Polyester PET and Polyethylene Naphtalate PEN Capacitors

Sometimes polyester capacitors are called Mylar. The abbreviation PET above comes from Poly-Ethylene Terephtalate (also abbreviated PETP). On the pattern of European standards the common abbreviations is KT for film/foil design and MKT for metallized film. As ´polyester´ also Poly- Ethylene Naphtalate is using commercial abbreviation PEN.

Polyester PET Capacitors

The polyester film is most reliable and together with PP most used of the plastic films. It can be produced in thicknesses down to 0.7 μm (0.03 mils). Its tensional stability is high and its εr ≈ 3.2. This has facilitated manufacture of one for organic dielectrics very space-saving capacitor. A typical field of application is decoupling. Certain applications like switched mode power supplies (SMPS) require for filtering and decoupling purposes large capacitance and moderate losses which have made the MKT capacitor an attractive replacement for ceramic X7R capacitors. A common design may look like the one in Figure 26.

Furthermore the MKT capacitor can stand +125 °C. This has tempted a number of manufacturers to produce it in a chip design. But heat conditioned shrinking is most pronounced in PET capacitors. This has led to many setbacks just for the SM types. Today mainly two different methods apply for preventing such heat rises during the soldering procedures that they release a detrimental shrinking.

- The components are supplied with such encapsulations and electrode designs that the heat penetration into the component is obstructed.

- The molecular memory of the initial location before the elongation is deleted in a heat and pressure process during manufacture.

Thus the risk of shrinking is reduced with the latter method which is restricted to stacked designs only. Therefore the dimensions could be held down with a minimum of encapsulation. Then, however, the heat penetration will be higher and at temperatures of 230 °C the film material is damaged. One solves in other words the shrinking problem but increases risk of serious material damage. Soldering methods and temperatures have to be chosen and supervised so that the chosen capacitor type can stand these processes. An infrared (IR) reflecting film and IR soldering seem for the moment to be the only way out as long as we deal with traditional PET films. The latest films are more resistive specified for 125 °C and can endure peak temperatures reaching 235 °C at reflow soldering. The film manufacturer has altered the thermo-mechanical properties to reduce shrinkage when used as a dielectric in SMD capacitors.

The shrinking effects are best controlled by ESR measurements at the resonance frequency before and after soldering.

Advantages with PET

- Thin film with a high quality.

Disadvantages with PET

- The temperature dependence is comparatively large and non-linear.

- The dissipation factor is comparatively large, approximately 0.5% at 1 kHz.

- The material suffer from properties that in, for example, hi-fi applications (analogue technique) may give perceptible distortion.

Poly-Ethylene Naphtalate (PEN)

is a relative to polyester but somewhat more heat resistant. Capacitors with this dielectric often are presented under the title polyester. The material attracts the interest mostly for SMD designs. They are manufactured in stack technology with a film thickness of down to 1.5 μm (0.06 mils). According to some papers such chips are able to stand up to both wave and IR soldering but only IR and vapor phase soldering is recommended. However, recent developments and film improvements indicate a considerable step upwards in the temperature range. With a derating of the applied operating voltage above 125 °C an upper temperature of + 150°C is quite possible.

The material is still too expensive to be used on a large scale.

- Capacitance 1 nF… 10 μF.

- Tolerance ±5% and ±10%.

- Temperature range -55/+125°C (+150 °C).

- Rated voltage 16…400 V DC.

- Tanδ , 1kHz, 20°C, ≈ 0.4…0.5% (≤0,8%).

- IR, 20°C, ”typical” 30 000 s; ≥1 GΩ or ≥ 400 s.

- Stability ΔC/C ≤5%.

- TC ≈ +220±10ppm/°C (average over the temperature range).

- εr ≈ 3.2.

- Dielectric absorption ≈ 0.15 %.

- Recommended derating 0.6xVR.

Temperature and frequency dependencies

We will start with two three-dimensional diagrams that show how εr (and with that C) and Tanδ (DF) change with frequency and temperature. Specified measurement points have been inserted as ovals in the diagrams (Figure 27. and 28.).

The diagrams are interesting because they show how temperature and frequency rule the parameters in a complicated manner, especially Tanδ .

The following diagrams are more common and easy to interpret. In some of them there are curves inserted for a PEN, i.e., Poly Ethylene Naphtalate. It is comparatively more temperature resistant than PET and for that reason used in SMD types.

Among the curves over the frequency dependencies of impedance there are shown typical resonance frequency ranges. Because there are comparatively small changes of capacitance and the losses are rather small impedance diagrams get a pliable bend downwards into a sharp tip around the resonance frequency. Examples of resonance frequencies are shown in Figure 34.

The temperature dependence of capacitance is influenced also by its magnitude, by the dielectric thickness and the design of the winding. This is reflected in the distribution at higher temperatures.

The frequency dependence of capacitance is ruled not only by the material but, to some extent, also by its magnitude and capacitor construction (foil or metallized design). Sometimes there are shown examples of series capacitance measurements where an apparent increase occurs at higher frequencies. This increase is hinted by the dotted line in Figure 30.

Also the frequency dependence of losses is ruled by the capacitance magnitude and by the design. While the dotted curve may represent a metallized design (MKT) in the magnitude of some hundred nF the foil capacitor (KT) is localized in the lower part of the curve area.

Other manufactures and other module distances give other resonance frequencies. Always check with the manufacturers’ data sheet.

The seemingly sharp points in the impedance curve look in another magnification somewhat more round. Figure 35. shows results from measurements of MKT, MKC and MKP capacitors, 100nF. The slightly lower losses for MKC and MKP capacitors is shown as a lower ESR.

Failure modes

Bump, vibration and temperature cycling may in, above all hermetic cans, cause interruption in internal termination leads or in the connecting link terminal lead – spray metal compound – metallizing. Types that are molded into epoxy run less risk. If the casing on the other hand consists of plastic humidity will diffuse into the component. Humidity, however, impairs primarily only in the state of liquid (for example at a condensation) which will cause electrolysis, especially in the presence of a DC load. Thus non-hermetic components of this type or SMD design can bear a high RH, at least for 1000 hrs. If we can accept a C of +3 to +5% (εr for water approximately 80) and a decreasing IR there is no harm done. When the moisture content outside of the component decreases the humidity diffuses out of the winding and the capacitance increase goes back. If the component on the other hand operates in a jungle climate for months the IR will decrease until the leakage current starts electrolysis in the metallization. It will end in an open circuit.

Polypropylene PP / KP and MKP Capacitors

The common European abbreviations for polypropylene capacitors is PP or KP for film/foil and MKP for metallized film.

Introduction

Polypropylene (PP) is from a molecular point of view a non-polar dielectric with small losses and a relatively straight and moderate TC. Since the smallest film thickness is approx. 3.5 μm (0.14 mils) and εr ≈ 2.3 the capacitor can not come down to those sizes characterizing PET at low rated voltages. But remaining good characteristics in many applications have brought up PP as a replacement for polycarbonate (PC) and polystyrene (PS), not least as a precision capacitor. PP exists in both foil and metallized design and is adopted for both AC, pulse and transient suppression (X-capacitor) applications. The pulse and X-capacitor designs, however, require a specific metallizing technology.

The MKP design had from the beginning problems with the adhesion between the metallized layer and the plastic film. This problem characterizes non-polar dielectrics consisting of molecules and has caused many problems at, for example, gluing of components to circuit boards. The plastic surface film has to be raised and roughened which among other things can be done by etching, flame exposure, electron irradiation or corona. Today the MKP design is well established and the adhesion problems a passed period.

The demand for filtering / interference suppression of thyristor generated noise voltages has brought forth the same type of large capacitors as shown for PET but here the low ESR losses allow quite different r.m.s. currents, for example at high frequencies.

The recommended absolute maximum temperature is +105°C. We recommend max +85°C with the remark that developments of new films is going on to offer temperature range above +105°C as a maximum operating temperature. Current temperature limitations still make PP difficult for chip designs.

Temperature and frequency dependencies

The frequency dependence of capacitance for PP capacitors is moderate. In Figure 38. the broken part of the curve indicates an increase of capacitance. This increase is not physical but depends on influence from series capacitance measurements.

Note in Figure 39. the outstanding low loss factor for PP over the whole temperature range. The curve area in Figure 40. represents capacitance up to some hundreds of nF. The higher capacitance, the greater losses.

Designs with foil or hermetic seal have somewhat higher IR than corresponding metallized and plastic encapsulated types.

Thermal Model

Video with in-depth explanation of thermal polypropylene film capacitors can be find here: Thermal Model of PP Film Capacitors (passive-components.eu)

Failure modes

Any characteristic failure mode just for PP capacitors is not distinguishable. Here what was said about PET usually applies.

Polycarbonate (PC) capacitors / KC and MKC

For a long time the polycarbonate capacitor has been predominant among metallized precision capacitors. Nowadays, however, the PP capacitor has taken over more and more applications from the PC. Where one has been able to disregard the TC differences the foil design of the PC often has replaced polystyrene PS but also here PP capacitors are replacing those of polystyrene. The manufacture of PC film therefore is declining and, will eventually cease. We shall have a closer look on reasons and characteristics.

Introduction

The polycarbonate film is unlike other plastic films prepared from an emulsion that is dried. Its least thickness is stated to 1.5 μm (0.06 mils) and its εr to 3.0 at 1 kHz and room temperature. This film has small dielectric losses, a high IR, a small temperature dependence and a maximum temperature that by many manufacturers was specified to +125 °C. Thus it was rapidly popular, not least in precision capacitors.

Because there is a certain risk of increasing IR failures above +100 °C we recommend this ambient as a maximum or, not more than that of the manufacturer’s data sheet if they specify a lower temperature.

Genuine SMD designs are missing but there are examples of broad spread-out metal strap terminals reminding of the Gull wing design. But check if it is a single source situation.

Temperature and frequency dependencies

Failure modes

Some mysterious short circuiting failures were reported from precision capacitors in high impedance low voltage space applications. In 1982 a Voyager satellite was met with a failure in a 8 μF/ 75V polycarbonate capacitor. Half-way to Jupiter the IR suddenly dropped from hundreds of MΩ to 2.8 kΩ. All over the world component experts worked with this kind of problem and by and by the picture became clearer. The reasons are resulting effects of a self-healing.

The issue is a critically high carbon deposit in former self-healing sites, which is connected with the high carbon contents in the polycarbonate film. But the failure only appears in that very narrow application sector where just precision capacitors usually are used, namely at low voltages and in high impedance circuits, e.g. integration and ramp voltages. Even that very low energy needed to burn away the formed carbon string may be missing. The cure is some kind of Burn-in treatment. From a failure rate in the magnitude of, say one per cent, we should get down to or below one per thousand. The most sophisticated (and expensive) Burn-in program we find in US MIL-C-87217. In conclusion it is built on a collection of all those environments which are regarded to release this kind of short circuits: cyclic voltage ramps with polarity changes + gradual temperature fluctuations.

Polystyrene (PS), Polyphenylene Sulfide (PPS), Teflon (PTFE) and Polysulfone (PSU) Film Capacitors

Polystyrene (PS) represents a non-polar dielectric material that just as polycarbonate to a great extent has been replaced by polypropylene. The availability is strongly limited due to ceased production.

Polyphenylene Sulfide or simply PPS has come to stay mainly because of its relatively high temperature resistance which has allowed SMD manufacture.

General Comments to PS

εr ≈ 2.4. Max. temp.+70°C (possibly +85°C). Smallest film thickness 4 μm (0.16 mils). Except for metal foils often double metallized plastic foils are used.

Advantages

- Very low losses; 0.01% at room ambient and 1 kHz.

- Very high IR; RC 200 000 s. Actually it’s more exterior factors that determines the IR than the material itself.

- Dielectric absorption 0.02%.

- Stability ΔC/C, max ± 0.5%.

Disadvantages

- Can not be metallized due to high carbon deposits and too little oxygen available at a self-healing breakdown.

- Chemically sensitive film.

- Availability limited due to ceased production.

Temperature and frequency dependencies for PS

General comments to PPS

Foil types exist but metallized design is a rule. If nothing else is said metallized film applies.

εr ≈3.0. Max. temp.+140 °C; most manufacturers recommend maximum +125 °C. Dielectric absorption ≈ 0.1%.

Smallest film thickness is 1.2 μm (0.05 mils) but former quality problems with the thinnest film may give cause for stronger derating of the lowest rated voltage. However, the supply of film is stabilized thus indicating an established demand..

The film is used in capacitors both for lead mount and SMD. Existing chip types are made in a stacked design.

Temperature and frequency dependencies for PPS

Other plastic organic film capacitors used in special designs:

Teflon (PTFE)

Teflon exists both in metallized and foil design. The greatest advantage of the film is its temperature resistance. The price, on the other hand, is high which gives cause for exclusive hermetic designs.

- Capacitance 470pF….4.3μF.

- Tolerance ±0.25….±20%.

- Temperature range -65/+200°C.

- TC -200…+50ppm/°C.

- Rated voltage 50…600 V DC.

- Tanδ , @ 1kHz, 20°C, ≤0.1%.

- IR, @ 20°C, foil ≥500GΩ/ ≥100 000s,

- IR, @ 20°C, metallized film 50GΩ/ 10 000s.

- Stability ΔC/C max -1%.

- εr ≈ 2.2.

- Dielectric absorption ≤0.02%.

- Recommended derating 0.6xVR.

Polysulfone (PSU)

Polysulfone capacitors belong to the same price group as the one of teflon. They are used only in special applications where high temperature capabilities together with excellent characteristics are of vital importance. The capacitors have been manufactured only in hermetic design and with foil electrodes.

- Capacitance 1nF….22μF.

- Tolerance ±0.25….±10%.

- Temperature range -65/+150°C.

- TC -200…+50ppm/°C.

- Rated voltage 50…400 V DC.

- Tanδ , @ 1kHz, 20°C, ≤0.15%.

- IR, @ 20°C, foil ≥1000GΩ

- εr ≈ 3.2.

- Dielectric absorption ≤0.2%.

- Recommended derating 0.6xVR.

FAQ Film Capacitors

They are electrostatic capacitors that use plastic films (such as PET, PP, PPS, or PTFE) as dielectric materials, often combined with foil or metallized electrodes, to achieve high voltage endurance, low losses, and long-term stability.

They are widely used in DC link circuits for renewable energy and automotive systems, AC motor start circuits, EMI suppression, medical defibrillators, railway systems, and defense hardware.

Polypropylene capacitors offer low dissipation factor, high breakdown strength, and excellent frequency stability, making them ideal for high-frequency AC, snubber circuits, and high-current DC applications.

Self-healing is a process where localized dielectric breakdowns vaporize the metallization around the defect, isolating the fault and allowing the capacitor to continue functioning reliably.

No, polyester capacitors exhibit significant capacitance variation with temperature and are better suited for general-purpose applications like blocking, bypassing, and decoupling.

What are film and foil organic dielectric capacitors?

How-to Select the Right Film Capacitor

- Define the application requirements

Identify whether the capacitor will be used in high-frequency AC, DC link, EMI suppression, or precision timing circuits.

- Match dielectric material to performance needs

Choose PET for cost-effective general use, PP for high-frequency and high-current circuits, PPS for precision stability, or PTFE for extreme temperature environments.

- Consider voltage and temperature ratings

Ensure the capacitor’s rated voltage and operating temperature range align with the system’s requirements.

- Evaluate size and cost constraints

Balance dielectric constant, physical size, and budget. For compact designs, PET may be preferred, while PP and PTFE are better for performance-critical systems.

- Verify reliability features

Look for self-healing capability, impregnation quality, and encapsulation type to ensure long-term durability in demanding environments.