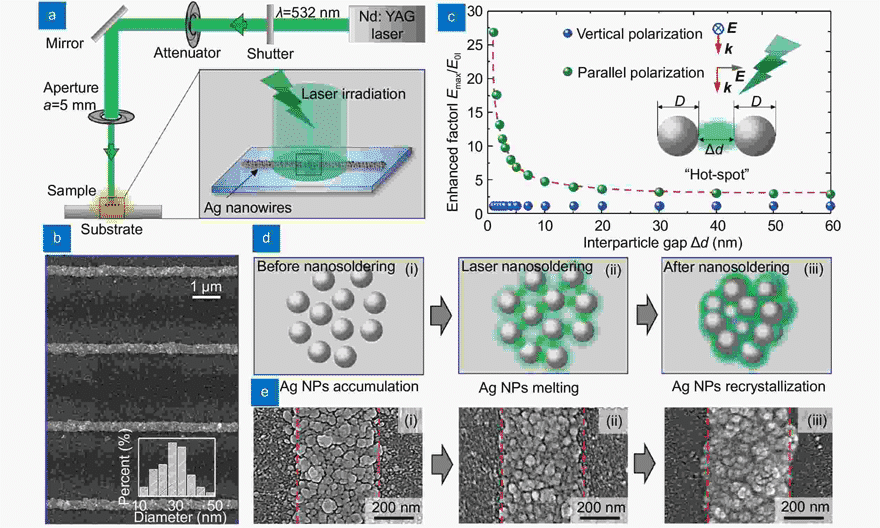

Researchers at Jinan University and the Chinese Academy of Sciences developed a plasmon-enhanced laser nanosoldering technology to increase the electrical conductivity of silver (Ag) nanowires that are fabricated using femtosecond laser direct writing (FsLDW).

This technology could provide an efficient, cost-effective way to rapidly produce large-area metal nanoelectrodes and capacitors that are uniform, flexible, and highly conductive.

FsLDW is used to build Ag nanowires for engineered patterns in 2D and 3D, and that have submicron resolution. This nanofabrication method offers many advantages, including high resolution, true three-dimensionality, and flexibility. It is widely used in the fabrication of optoelectronic devices.

There is one challenge to using this method, however; the Ag nanowires built using FsLDW are composed of aggregates of Ag nanoparticles with void or polymer inclusions that reduce electrical conductivity.

To increase conductivity and reduce the resistance of direct-write Ag nanowires, the researchers aimed to reduce the gaps and increase the contact area between the Ag nanoparticles — thereby reducing the amount of energy dissipated by the conductive electrons in the electrode.

The researchers used the photothermal effect to significantly increase the contact area of adjacent Ag nanoparticles.

Plasmon-enhanced laser nanosoldering — the method used by the researchers to enhance the electrical conductivity of the Ag nanowires — takes advantage of the structural characteristics of the FsLDW-fabricated Ag nanowires.

The nanowires are composed of aggregates of nanoparticles that are reduced by the multiphoton absorption effect. Plasmonic hot spots are generated between the nanoparticles under laser irradiation.