In a collaboration between Murata Manufacturing Co., Ltd., and the National Institute for Materials Science (NIMS), researchers have compiled a comprehensive new database of dielectric material properties.

This database is a treasure trove of information, meticulously curated from thousands of scientific papers.

The study, published in Science and Technology of Advanced Materials: Methods, not only presents this valuable resource but also offers valuable insights that could significantly accelerate the development of next-generation electronic materials and energy storage technologies.

Artificial Intelligence (AI) has the potential to revolutionize materials discovery, but it relies on extensive and diverse datasets. The absence of such data remains a significant obstacle in the field.

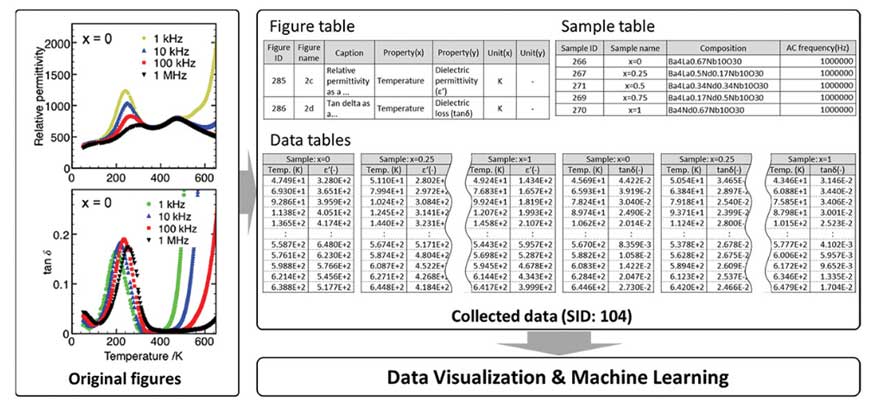

To address this challenge, researchers employed the Starrydata2 web system to collect experimental data on over 20,000 material samples from more than 5,000 publications. The National Institute of Materials Science (NIMS) team developed a standardized approach to extract data from graphs, including temperature-dependent properties that are often overlooked in other databases. The researchers emphasized the meticulous process of manually tracing graphs and correcting inconsistencies in original research papers to create a clean and high-quality dataset.

The database focuses on a specific class of materials crucial for electronics and holds the distinction of being the largest ever reported, significantly surpassing previous collections. Equipped with this wealth of information, the team utilized machine learning (ML) to predict the properties of materials and their electronic behavior.

While the ML models demonstrated effectiveness, they initially operated as “black boxes,” rendering the reasons behind their predictions opaque to the researchers. To comprehend the context behind these predictions, the team created visual maps of the data, simplifying the interpretation of complex information.

Additionally, they employed clustering algorithms to automatically group similar materials, enabling them to identify patterns in how a material’s composition influences its properties. This analysis not only allowed them to categorize the materials into distinct groups, including seven prominent ferroelectric families, but also provided a comprehensive overview of the entire compositional space.

The team delved deeper into ABO3 Perovskites, a family of materials crucial in everyday electronic devices and energy storage technologies, such as smartphones, computers, and solar cells. Their visualizations revealed a straightforward connection between the material’s fundamental structure and its dielectric permittivity, aligning with existing academic knowledge.

This groundbreaking research advances our comprehension of dielectric materials and transcends conventional trial-and-error methods. The team explained, “By compiling the largest dataset ever and employing diverse machine-learning techniques, we achieved unprecedented detail in visualizing the entire compositional landscape.”

The NIMS team intends to make the dataset publicly accessible next year, enabling scientists globally to harness its potential for groundbreaking discoveries. Future endeavors may involve expanding data collection to encompass manufacturing methods and processing conditions, facilitating more comprehensive predictions that establish direct links between production processes and material properties.

The researchers concluded, “We fervently hope that this foundational work will inspire similar data collection initiatives and novel approaches to materials discovery. Ultimately, this will lead to more intelligent materials development pathways that benefit society through enhanced electronic technologies.”