METCOM metal composite power inductors have an advantage over traditional ferrite inductors because of the core high saturation flux density, which enables a stronger magnetic field. KEMET published a blog article to explain more in-depth about the technology.

Inductors are one of the most widely used electrical and electronic circuits components, along with capacitors and resistors. An inductor is a passive energy storage component that stores magnetic energy. The construction of an inductor is relatively simple, consisting only of a wire wound into a coil. The circuit symbol of the inductor is as following:

Basic Electrical Characteristics of Inductors

Ohm’s law in the case of an inductor is expressed through the following equation:

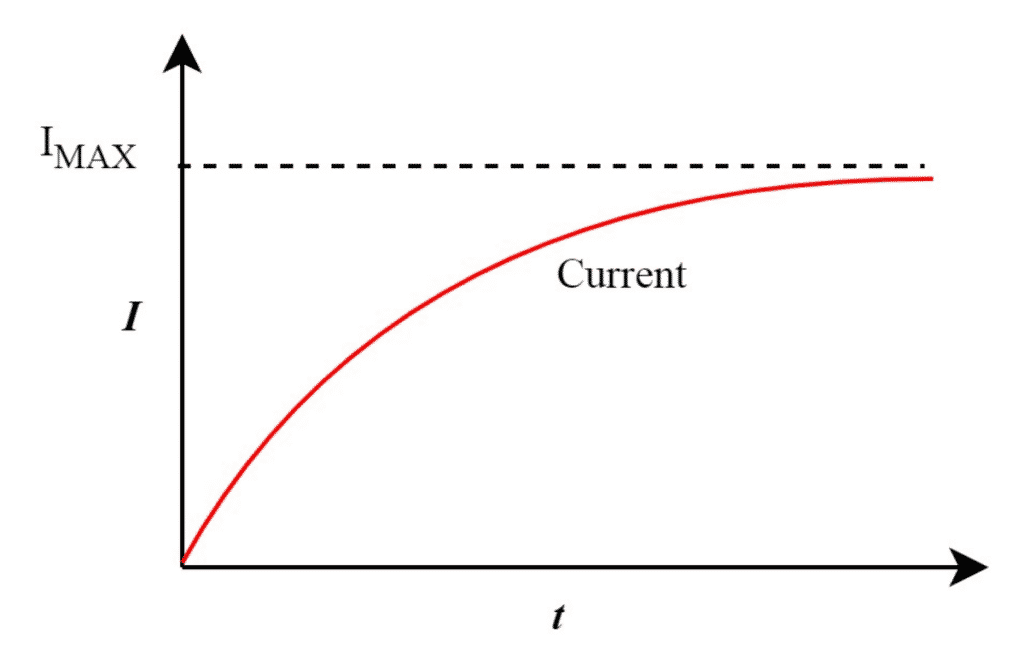

This equation tells us that the rate of change of current through an inductor is not instantaneous. When an inductor is powered up, a voltage is developed across the inductor immediately. However, the current through the inductor does not change abruptly. In simple words, inductors resist change in current — the current through the inductor changes in an exponential manner, as shown in the Figure 2. For a purely inductive circuit, the voltage leads the current by 90o. The voltage and current waveforms for a purely inductive circuit are shown in the Figure 3:

Inductors are found in all types of electrical machines and devices that rely on manipulating magnetic energy for their operation. Examples of such machines and devices include motors, transformers, relays, speakers, and power supplies. Windings and coils inside motors, transformers, and generators are examples of inductors.

METCOM Power Inductors

The construction material of inductors plays a vital role in determining the performance characteristics of inductors. A major application of inductors is in DC-DC converters and switch-mode power supplies. Inductors are frequently used at the input and output stage filters of switching power supplies. However, inductors made from conventional materials often fall short in performance when it comes to demanding automotive applications. However, metal composite inductors are an ideal solution in automotive SMPS (Switching Mode Power Supply) applications.

The first advantage of metal composite inductors is the high saturation characteristics that provide higher tolerance for current transients. The inductance of a coil varies with temperature. However, METCOM inductors can significantly reduce this issue. These inductors offer stable performance over an extended temperature range. The maximum operating temperature of MPEV series METCOM inductors is 180oC.

Advantages and Applications

METCOM MPEV series metal composite power inductors are designed explicitly for DC-DC switching power supplies in the automotive industry. METCOM power inductors can be used in switching power supplies as power inductors and EMI filter inductors. Some of the prominent applications of METCOM power inductors in the automotive industry are :

- LED headlights

- Instrument cluster panels

- Head-up displays (HUD)

- Electric oil pumps (EOP)

- Electric water pumps (EWP)

- Electric power steering (EPS)

Advantages of METCOM MPEV power inductors are:

- Higher tolerance for current transients

- SMD configuration

- Inductance range from 0.47-47 μH

- Maximum operating temperature: 180oC

- Low acoustic noise

- Low magnetic leakage flux

- AEC-Q200 qualified

Switch-mode power supplies operate at high frequencies and have power ratings. Due to this reason, the power supply circuit is always at the risk of over-heating, current transients, and electromagnetic interference. All these issues can lead to circuit damage and components failure. The composite metal construction of METCOM inductors ensures higher tolerance for current transients and higher operating temperatures. Hence, the reliability and durability of the power supply are improved significantly. Moreover, low acoustic noise and magnetic leakage flux improve the power efficiency of the SMPS (Switching Mode Power Supply).

KEMET’s research, materials science, and development of magnetic powder provide METCOM power inductors with excellent heat resistance characteristics. Hence, the heat resistance performance of METCOM power inductors is far higher than its competitors, as shown in the following graph.

The metal composite core of the power inductor consists of magnetic powder, binder material, and insulation coating. This composite material ensures superior performance and electrical/thermal characteristics. The isolation coating is necessary to prevent particle-to-particle contact such that the core material is discontinuous. The discontinuity of the core material prevents the early magnetic flux saturation due to eddy currents that. A saturated core cannot carry more magnetic flux and results in loss of energy due to heating. The temperature resilience of the coating is what enables the high temperature operation of MPEV. Significant advantages offered by the composite metal construction include stable inductance value, lower leakage losses, reduced core stress, and low temperature.

Automotive Switch Mode Power Supplies

Right now, the EV industry is going through a boom and will dominate the automotive landscape in the coming years. Switch-mode power supplies have always been an integral part of any car’s electrical system. However, with the advent of EVs, the importance of these power supplies has increased exponentially. From headlights and indicators to power steering and infotainment systems, all the electronic subsystems of a vehicle depend on switching power supplies for their operation. Additionally, safety-critical systems such as ABS, airbags, cruise control, collision avoidance, and power steering all rely on high-performance power supplies. Therefore, the reliability and safety of automotive power supplies are of utmost importance. Failure or malfunction of a power supply can lead to the loss of a critical subsystem, thus resulting in accidents and injuries. In this context, the use of reliable circuit components is crucial. KEMET METCOM power inductors meet the safety, quality, and performance standards required by the conventional and EV automotive industry. With their superior composite metal technology, these inductors provide stable inductance and offer higher power and temperature ratings.

KEMET METCOM MPEV power inductors are also valuable for applications in other industries apart from the automotive industry. These power inductors can be used in DC-DC converters and switch-mode power supplies used in power converters, automation systems, and image processing systems. METCOM power inductors can effectively be used in DC-DC converters up to 48 V.

Product Family

METCOM power inductors can be grouped into three families:

- MPX

- MPXV

- MPEV

The MPX family of inductors is suitable for consumer, commercial, and industrial-grade applications. The inductance range available for this family is 0.1-100 µH. MPXV and MPEV families of power inductors are designed specifically for automotive applications and are AEC-Q200 qualified. The available inductance range for the MPXV family is 0.1-100 µH, whereas, for MPEV, it is 0.47-47 µH. MPX and MPXV reach up to 155°C operating temperature, while MPEV inductors go even, up to 180oC.

Metal Composite vs Ferrite Inductors

A comparison of metal composite and Ferrite inductors is provided in the following figure 8: