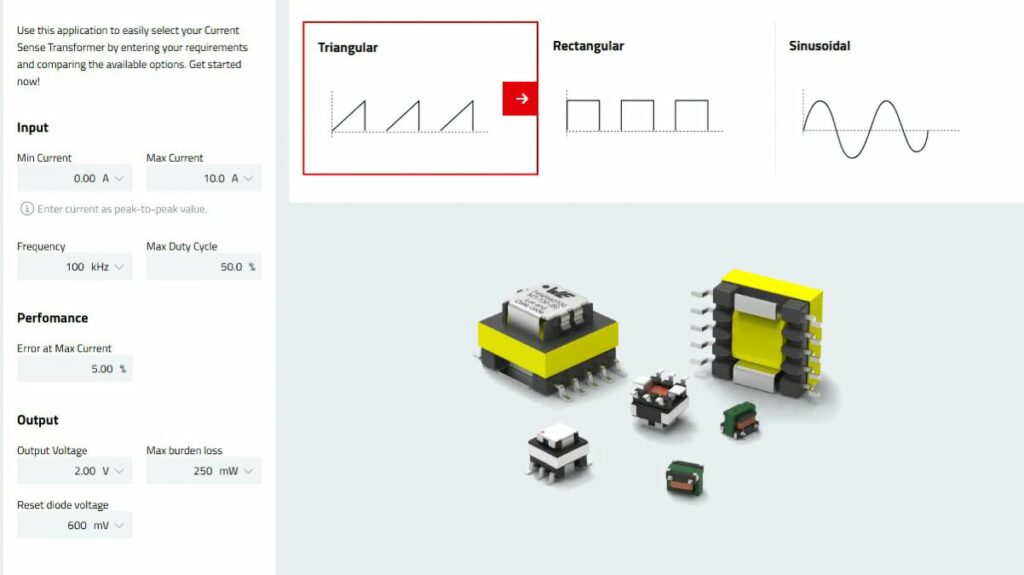

Würth Elektronik has added a dedicated Current Sense Transformer Selector to its REDEXPERT online design environment, aimed at simplifying current sense transformer (CST) selection for power electronics designers.

The tool combines a parametric selector with measurement‑based simulation to reduce trial‑and‑error in choosing suitable CSTs for demanding AC current measurement tasks.

Why current sense transformers matter

Current sense transformers are widely used for measuring alternating current in power conversion and protection circuits. Compared to shunt‑based sensing or Hall sensors, they provide galvanic isolation, low power dissipation in the measurement path, and high immunity to common‑mode noise, which is particularly attractive in high‑frequency switched‑mode power supplies and metering applications.

For many development teams, the practical challenge is not whether to use a CST, but which specific component will handle the required current and frequency range without saturation, overheating, or unacceptable measurement error. This is where the Würth Elektronik REDEXPERT Current Sense Transformer Selector is positioned.

Key features and benefits

The new Current Sense Transformer Selector is an extension of the existing REDEXPERT design platform from Würth Elektronik. It focuses specifically on helping engineers find suitable devices from the WE‑CST product family for their target operating conditions.

Key characteristics of the selector include:

- Input of application‑relevant parameters such as current, frequency, signal type, and permissible maximum error.

- Automatic filtering of Würth Elektronik current sense transformers that match these parameters from the internal product database.

- Display of a component list with key parameters for quick comparison.

- Simulation of temperature rise as a function of current and frequency.

- Simulation of measurement error versus frequency and current.

- Side‑by‑side comparison of multiple CST options in a common simulation view.

- An overview page for each candidate part, consolidating the most relevant information for design‑in.

A notable aspect is that the simulations are based on actual measurements rather than purely analytical models. For engineers, this can significantly reduce the need for early hardware prototypes purely for CST evaluation, especially when exploring several options in parallel.

Practical benefits over manual selection

Without this selector, engineers typically have to interpret datasheet values such as the ET constant and thermal limits, then run lab tests across the real operating range to validate saturation behavior, temperature rise, and error. Datasheets rarely cover every combination of current, frequency, waveform, and ambient condition that occurs in practice. The REDEXPERT approach helps bridge this gap and allows designers to converge on a smaller shortlist of CSTs before going to the lab.

Typical applications

Current sense transformers are used across a broad range of AC measurement tasks in power electronics and energy systems. Würth Elektronik highlights the following typical use cases:

- AC current measurement in mains and distribution circuits.

- Switched‑mode power supplies, where CSTs can be used for primary current monitoring or feedback.

- Overload detection in power conversion and motor drive systems.

- Load shedding or shutdown detection in protective circuits.

- Energy metering and load measurement in instrumentation and smart grid equipment.

- High‑frequency current sensing in converters, inverters, and RF‑related power stages.

In many of these applications, galvanic isolation and high common‑mode rejection are essential for safety and measurement accuracy. Using a transformer rather than a resistive shunt can also help minimize power loss and self‑heating on the measurement path, which is important in high‑current or thermally constrained designs.

Technical highlights

While the press information focuses on the design tool rather than individual part numbers, it implicitly touches on several important technical aspects of CST selection that the selector helps to manage.

ET constant and saturation

One of the core sizing parameters for a current sense transformer is the ET constant, which effectively links the applied volt‑seconds on the primary to the allowable flux density in the core. In practice, this means the chosen CST must not reach saturation even under the worst‑case combination of low frequency and high current in the target application.

With the REDEXPERT selector, engineers can:

- Enter their expected current range and frequency band.

- See which CSTs maintain acceptable error over that range.

- Check, via the simulation, whether the transformer remains in a linear region and avoids saturation.

This is especially relevant in applications with wide operating ranges, or with startup and fault conditions that differ significantly from nominal operation.

Thermal behavior and temperature rise

At high currents and frequencies, core and copper losses can raise the temperature of the transformer above safe limits. The selector’s temperature‑rise simulation makes it easier to:

- Estimate how hot a given CST will run at specified current and frequency.

- Compare multiple candidates at a glance and eliminate those that would overheat at maximum load.

- Reserve sufficient thermal margin for ambient temperature, nearby heat sources, and enclosure constraints.

In practice, this can help avoid over‑conservative designs (oversized transformers) as well as under‑specified parts that would fail or drift out of specification in the field.

Error characteristics and measurement accuracy

Measurement error in a current sense transformer depends on several mechanisms, including magnetizing current, leakage inductance, and the design of the burden resistor and signal conditioning circuitry. The REDEXPERT selector focuses on:

- Providing error curves versus frequency and current.

- Allowing designers to set an acceptable maximum error as an input parameter.

- Making visible where a given transformer meets or exceeds the required accuracy envelope.

For applications such as metering, overload detection, or control loops in power converters, this visibility into error behavior is crucial when selecting an appropriate CST.

Availability and part families

The selector works against Würth Elektronik’s current sense transformer portfolio, including the WE‑CST series. According to the manufacturer, all suitable devices that match the user’s input parameters are returned from the product database, so designers can expect to see the available options that realistically fit their operating conditions according to the manufacturer’s datasheet and internal measurements.

For detailed electrical and mechanical specifications of individual current sense transformers (such as turns ratio, isolation voltage, dimensions, creepage/clearance, and temperature range), engineers should refer to the corresponding datasheets and catalog documentation. Those documents remain the reference for final qualification and release into a design.

Design‑in notes for engineers

From an engineering perspective, the REDEXPERT Current Sense Transformer Selector can be used as a practical step in the design flow for AC current measurement:

- Early concept phase: Use the tool to explore whether a CST is feasible for the desired current and frequency range, and to get an indication of transformer size and performance.

- Pre‑layout design: Narrow down candidate parts based on error, temperature rise, and size constraints, then download datasheets for detailed checking against creepage/clearance and isolation requirements.

- Lab validation: Focus prototype measurements on a small set of shortlisted CSTs, using the REDEXPERT simulation curves as a reference when debugging or tuning burden resistors and signal conditioning.

Some practical selection hints when using the tool:

- Start by entering realistic worst‑case conditions for current and frequency, not only nominal values.

- Set the maximum error target according to system‑level requirements (for example, protection thresholds or metering accuracy class), then see which CSTs still meet that constraint at the extremes.

- Inspect the temperature‑rise curves to ensure sufficient margin to the maximum permissible component temperature; consider the actual ambient and self‑heating in the final device.

- Use the side‑by‑side comparison to compare a smaller transformer versus a slightly larger one and decide whether the size saving justifies any increase in loss or error.

Even with a powerful selector, it remains important to consider PCB layout (loop area, coupling to noisy nodes), burden resistor selection, and filtering in the analog front end to achieve stable and accurate current measurements in real hardware. The REDEXPERT tool helps reduce guesswork on the magnetic component side so that engineers can focus more on the overall measurement chain.

Source

The information in this article is based on a manufacturer press release about the REDEXPERT Current Sense Transformer Selector and its capabilities for selecting Würth Elektronik current sense transformers, complemented with general engineering context for current sense transformer design‑in.