Source: TDK news

The APEC is one of the leading events for power electronics in the USA. On display from EPCOS and TDK products are solutions for automation, drives and traction. In particular, capacitors, inductors and protection devices will be on show.

Product highlights

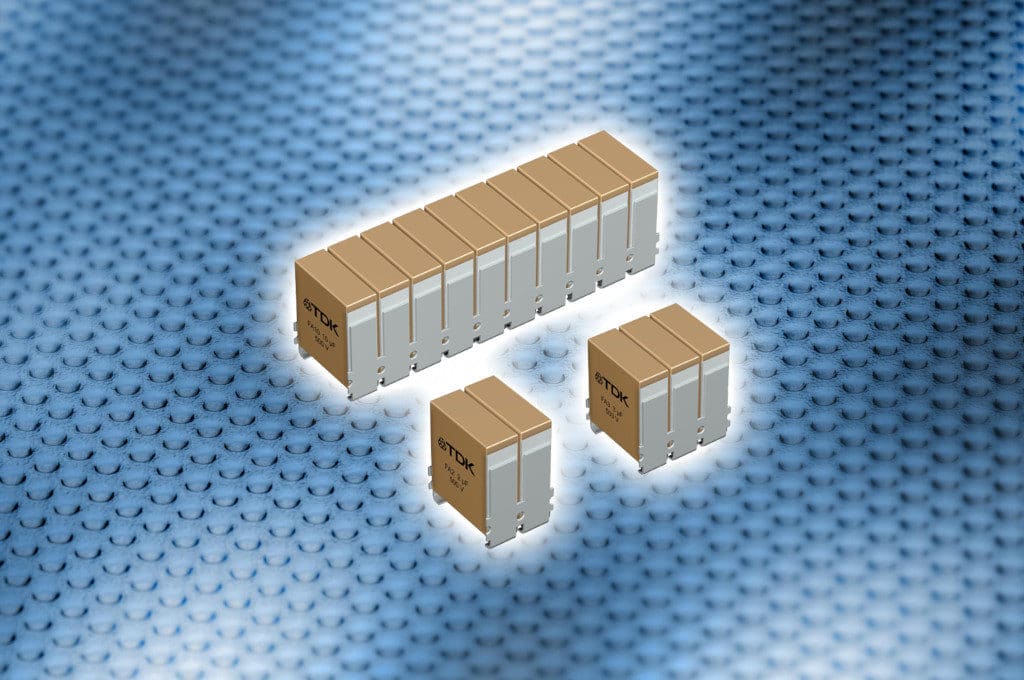

CeraLink in modular flex-assembly technology

The proven CeraLink® capacitors are now available with FA types in modular flex-assembly technology. This space-saving design connects two, three or ten identical capacitors in parallel over the same terminals in order to increase the capacitance.

The new CeraLink FA types are available for rated voltages of 500 V DC, 700 V DC and 900 V DC. Depending on the voltage and number of capacitors, this results in rated capacitance values of between 0.5 µF and 10 µF.

One particular feature of these capacitors based on PLZT (lead lanthanum zirconate titanate) ceramics is their high permissible operating temperature of 150 °C. The FA types have a width of 7.4 mm and a height of 9.1 mm; while the lengths are 6.3 mm, 9.3 mm or 30.3 mm. Despite their small size, they feature a ripple current capability of up to 47 ARMS.

One major advantage of the parallel switching is the extremely low ESR values that are significantly below 10 mΩ at high frequencies in the range from 0.1 to 1 MHz. With a minimum of 3 nH, the ESL values are also extremely low.

Thanks to their low parasitic effects, CeraLink capacitors are ideally suited for converter topologies on the basis of fast-switching semiconductors such as GaN or SiC. Voltage overshoots when switching are significantly lower than with conventional capacitor technologies. Special requirements in terms of size, current capability and temperature can also be met very easily with CeraLink capacitors.

HVC series with high current capabilities up to 500 A

The HVC series of high-voltage contactors has been expanded with the new HVC300 and HVC500 types with current capabilities of 300 A and 500 A, respectively. The new contactors can switch high voltages of up to 900 V DC, while types for 1200 V DC are available on request.

Their gas-filled switching chamber ensures that arcs are safely and quickly extinguished when the current is switched off. Thanks to the extremely fast switching capability of the HVC high-voltage contactors the duration of arcs is especially short, thus enabling reliable operations over the entire lifetime of the contactor.

The new types have the same compact design as the HVC200 for 200 A with the same dimensions of 89 mm x 44 mm x 93.5 mm (l x w x h). Like the HVC200, the new high-voltage contactors are available with coils for operating voltages of 12 V or 24 V. In addition, the series includes types with an output for switching status detection.

The HVC series is especially suitable for use in battery management systems and DC charging stations in e-mobility applications. Further applications include DC traction systems, photovoltaic, energy storage systems, and uninterruptable power supplies (UPS). These applications require fast and reliable disconnecting from the DC source.

Stacked MEGACAP Type MLCCs with high capacitance

The new series of vertically stacked MEGACAP Type MLCCs combine high capacitance and low ESR. The new CA series offers rated voltages from 25 V to 1000 V and covers a capacitance range from 20 nF to 150 µF.

The new MLCCs are available with C0G, X7T, X7S, and X7R temperature characteristics. Thanks to their high capacitance values, the capacitors are suitable for the resonant circuits of wireless and plug-in charging systems, for example, for industrial vehicles and robots. They can also be used in smoothing and decoupling applications in industrial equipment.

The MEGACAP Type MLCCs feature metal lead frames attached to the electrode ends of the components to protect against board flexure cracks and solder cracks from thermal shocks. The metal material of the terminal has also been optimized to lower the ESR and achieve a higher ripple current capability. In order to enable a low profile with increased capacitance, TDK has adapted its MEGACAP stack design so that the MLCC elements are stacked side by side.

The vertically stacked design enables stacks with three or even more elements. Hybrid joints between the metal terminals and the MLCC are both soldered and clamped to prevent the individual MLCC elements from falling out of the lead frame at the increasingly higher reflow temperatures.

Soft-termination MLCCs with low ESR

The new CN series features terminal electrodes with a conductive resin layer that provides high mechanical robustness to protect against board flexure. At the same time, the new MLCCs offer a low ESR that is comparable to that of conventional MLCCs.

The CN series offers capacitance values ranging from 2.2 µF to 22 µF and rated voltages from 16 V to 100 V. Based on X7R dielectric material commercial grade and automotive grade types of the new MLCCs are available. The latter are qualified to AEC-Q200.

Soft-termination MLCCs, which are able to withstand the stress from board flexure, are an effective way to prevent short circuits when used in battery lines. Conventional designs that coat the electrodes completely with resin, however, lead to higher ESR and losses.

TDK has achieved the low terminal resistance values by applying the conductive resin layer only where the terminal electrode comes into contact with the PCB. Thanks to the low resistance of the terminal electrodes of the new CN series these MLCCs are suitable for battery lines in automotive and industrial robot applications, where they help to improve system reliability.

Series of rugged AC filter capacitors extended

The B32754* to B32758* series of EPCOS AC filter capacitors cover a range of voltages from 250 V AC to 400 V AC and offer capacitances of between 1 µF and 70 µF. The capacitors comply with IEC 61071: 2007 and are extremely robust, even at high humidity. This has been verified in a temperature, humidity, bias (THB) test at 60 °C, 95 percent relative humidity and an applied rated voltage for 1344 hours, corresponding to 56 days, in according to IEC 60384 14:2013/AMD1:2016 Grade 3 Test A.

The capacitors are designed for a maximum operating temperature of 105 °C, and their epoxy resin-filled case conforms to UL 94 V-0. Depending on capacitance and rated voltage, the lead spacing is 27.5 mm, 37.5 mm, or 52.5 mm.

Thanks to their robustness, the capacitors are suitable for demanding applications in industrial electronics. These include, for example, output filtering for power supplies, frequency converters for drives and renewable energy, or UPS systems.

Compact overvoltage protection with an integrated fuse

The EPCOS ThermoFuseTM family of fuse protected varistors has been extended with the new compact NT14 and NT20 series. The new ThermoFuse components feature a footprint that fits into existing circuit board layouts.

The NT14 series (disk diameter 14 mm) is designed to absorb maximum surge currents with an 8/20-μs pulse of 6 kA at rated voltages of between 130 VRMS and 680 VRMS, while the NT20 series (disk diameter 20 mm) has a surge current capability with an 8/20-μs pulse of 10 kA at rated voltages of between 130 VRMS and 750 VRMS. The NT14 and NT20 series offer a maximum energy absorption of up to 220 J and 480 J for 2 ms, respectively. Both series are available in 2-leaded and 3-leaded types, with the third lead used to monitor whether the fuse has been activated.

ThermoFuse varistors are uniquely designed disk varistors that are connected in series with a thermally coupled fuse and are therefore intrinsically safe. If the varistor overheats, the patented thermal fuse trips and isolates the varistor from the grid with unrivalled dependability.

This prevents any potential damage on the PCB or to components located near the varistor and increases the reliability of the equipment to be protected. Thanks to their thermal resistance and flame-retardant design of the epoxy coating, the ThermoFuse NT series meet UL 94 V-0 requirements, and are also listed as Type 4CA in UL 1449, 4th edition.