Brazil, although not the most well-known country when it comes to tantalite production, stands out as an important supplier of this valuable raw material used in the tantalum capacitor industry according to article written by Sandro Arruda da Silva, published by Ignea Brazil.

While most of the world’s tantalum production comes from Africa, especially from countries like Rwanda and Congo, the mineral wealth in Brazilian soil offers significant opportunities.

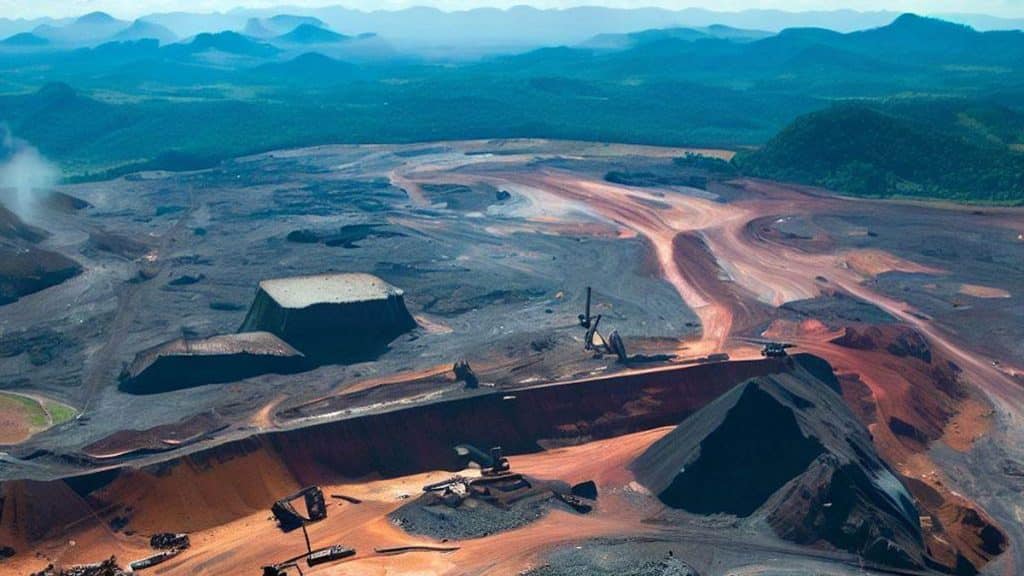

Challenges of Exploration in Brazil

The scarcity of in-depth studies on tantalum ore in Brazil is a relevant issue. The mineral is often found associated with the pegmatite body, which is formed by quartz, feldspar, beryl, and mica, making the measurement of its reserves a complex task.

Furthermore, the ore is often dispersed in alluvial deposits associated with other minerals such as gold or tin, as is the case with columbite, which is treated as a byproduct of cassiterite.

According to Sandro Arruda da Silva, CEO of Guru Blessed Minérios do Brasil and a mining expert, Brazil possesses significant potential reserves of tantalum and columbite, and the country needs to explore this resource more efficiently and sustainably.

“For 15 years, I have visited over 110 tantalum ore mines in Brazil, and I can confidently state that the largest reserves of tantalite and columbite are in Brazil. All that is needed is encouragement from the government, as well as streamlining the processes and licensing that sometimes stifle the mining sector, thus fostering illegal extraction that degrades the environment,” highlights Arruda.

Although the AMG company, located in Minas Gerais, was the only one to conduct an in-depth study of its reserves, identifying the largest volume of Ta2O5 in Brazil and producing its own ore, the country still has many mines that lack deeper studies.

Many of these mines operate under Garimpeira Mining Permission (PLG), as individual entrepreneurs or cooperatives, without the necessary investment in technology and modern concentration equipment.

The tantalum grades in Brazil vary according to the region and their occurrences. Paraíba and Rio Grande do Norte have higher grades, ranging from 20 to 45% Ta2O5, while in Amapá and Pará, the average is 10 to 18% Ta2O5, usually associated with variations of tin (SnO2) and higher grades of Nb2O5. When the Ta2O5 content is higher than Nb2O5, it is called tantalite, and when the opposite occurs, with Nb2O5 being higher, it is columbite.

Tantalum Production Process and Commercial Vision of the Ore

The tantalum ore production process involves several stages, including rock grinding and concentration through concentrator jigs, washing tables, spirals, centrifuges, and finally, magnetic separation.

It is essential to note that many regions, such as the state of Amapá, present significant concentration of Ta2O5 associated with gold, which can be an opportunity for producers, supporting the main production of gold.

“Brazil needs to have a more commercial vision for its mineral wealth, adding value to the final product and encouraging investments for the export of processed or beneficiated ore. This will generate more profits for producers, as well as boost economic growth, citizenship, and greater oversight in cities where mineral exploration occurs,” emphasizes the CEO of Guru Blessed Minérios do Brasil.

The Brazilian mineral sector has enormous potential, especially regarding the exploration of tantalum ore.