The Institute of Electrical Engineering of the Chinese Academy of Sciences has announced a significant breakthrough in the performance of film capacitor energy storage by using ultraviolet UV lamps irradiation in their manufacturing process.

In this breakthrough study, the excimer UV lamps nearly doubled the energy discharge density of capacitor films and increased the high-temperature “short-burst” performance by up to 52%.

Biaxially Oriented Polypropylene (BOPP) film capacitors are widely used for energy storage: in communication equipment, medical devices, and consumer electronics to ensure efficient energy transfer and storage. They are essential in electric vehicles (EVs) and other critical applications that require short bursts of increased power.

Currently, these BOPP films experience a bottleneck at high temperatures; a critical constraint EV, and other high temperatures. By utilizing UV lamps irradiation during manufacturing, this problem is reduced significantly.

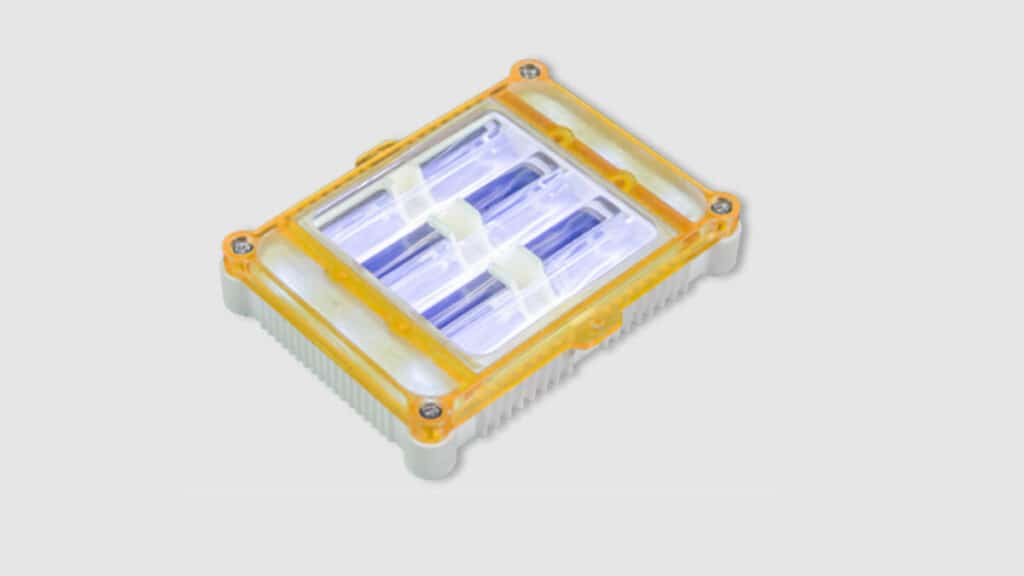

The breakthrough study utilized commercially available 172nm and 222nm ultraviolet excimer lamps developed by GMY company. These environmentally friendly lamps provide UV light with high photon energy. Primarily intended for UV curing technology GMY’s excimer UV curing technology uses 172nm UV light from the excimer lamp to break molecular bonds and promote cross-linking reactions between different monomer molecules, resulting in the functional curing of materials.

These UV lamps directly irradiated and modified BOPP in ambient air, forming better, thermally stable bonds without introducing any manufacturing issues.

The UV-modified BOPP film’s breakdown field increased by 52% at 120°C (248F). At room temperature, the energy discharge density improved from 4 MJ/m to 7.5 MJ/m, with a 17% improvement in the breakdown field.

A key element is this: applying UV to BOPP manufacture is a “soft” modification. The process doesn’t require any chemical reagents or produce high-pollution by-products. The simple addition of UV provides results with a single-step process, high throughput, and low energy consumption, and significantly improves the performance of energy storage capacitor films.

This method can be extended to other high-temperature dielectric films, demonstrating versatility according to GMY published article.