Vishay Intertechnology releases AEC-Q200 automotive qualified haptic feedback actuator that offers high force density, HD capability, and compact size. The customizable device features a compact, two-piece construction, 12 V operation, and temperature range to +105 °C for rugged automotive environments.

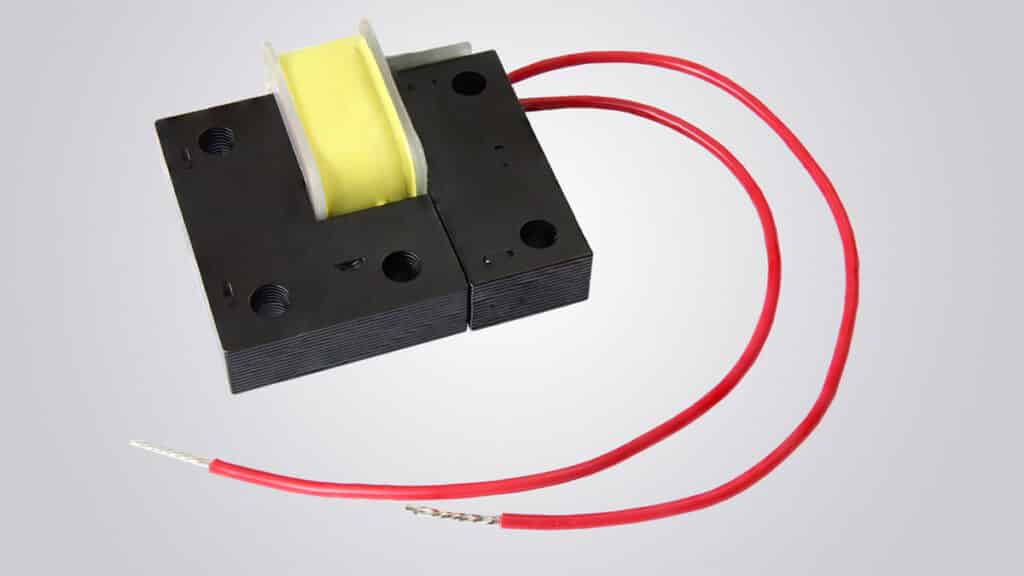

Vishay Intertechnology, introduced a new AEC-Q200 qualified customizable haptic feedback actuator offering 12 V operation for LCD displays, touchscreens, and touch switches in automotive applications. Featuring a compact, two-piece construction with mounting holes for easy installation and direct application of force, the Vishay Custom Magnetics IHPT-1411AF-ABA delivers high pulse and vibration capability for clear tactile feedback in noisy environments.

The Automotive Grade IHPT-1411AF-ABA is an electromagnetic device that converts electrical energy into a mechanical pulse or vibration for touch-based interaction that can be controlled by varying the input voltage amplitude and duty cycle. The haptic coil assembly, when energized by a DC voltage pulse, creates a magnetic field that attracts the mounted dynamic core piece. When deenergized, it returns the core piece back to its original position by springs or elastic material in the customer’s assembly.

The device’s fast response time of < 5 ms can be utilized to produce multiple high definition (HD) haptic effects with operating voltages up to 16 V. With an operating temperature range to +105 °C, the actuator is ideal for rugged environments. The device will be used in automotive dashboards, center consoles, and touchscreens for human-machine interfaces, and it can provide tactile feedback for electronic shift transmissions, steering wheels, seats, and other in-vehicle controls.

The IHPT-1411AF-ABA’s simple bobbin and core components allow designers to lay out a return spring configuration that can be incorporated into the display mounting, eliminating the need for additional housing. In addition, the device’s low 12 V operation eliminates the need for the additional high voltage supplies required by other technologies. As a result, the actuator can be implemented at up to a 40 % lower cost while reducing component height and delivering higher force density than competing technologies, including linear resonant, linear wideband, eccentric rotating mass, and piezo actuators.

The device released today can drive a 0.5 kg load to 6 g of acceleration with a 12 V, 5 ms pulse; competing technologies can only drive 0.1 kg to 0.2 kg to this level. The driving coil has an inductance of 1.8 mH, typical DCR of 0.95 Ω, and a coil to core dielectric withstand voltage of 150 VDC. RoHS-compliant, halogen-free, and Vishay Green, the actuator features standard lead terminations that are dipped in 100 % tin solder. Vishay can customize the IHPT-1411AF-ABA’s mounting orientation, termination types, and performance to any design’s specifications.

Samples and production quantities of the new haptic feedback actuator are available now, with lead times of 12 weeks.