This blog article by Knowles Precision Devices introduces basic facts of X2Y bypass capacitor with special X2Y electrodes layout, how it works and what is its performance.

X2Y® technology, which was originally developed by X2Y Attenuators, LLC, is based on a proprietary electrode arrangement embedded in passive components that can be manufactured using a variety of dielectrics.

Using this innovative technology, Knowles Precision Devices manufactures high-performance multi-layer ceramic capacitors (MLCCs) that we then use to create a variety of off-the-shelf and custom bypass and noise decoupling capacitors and electromagnetic interference (EMI) filters. Let’s look at how building these components with X2Y is different than using a traditional ceramic MLCC and the resulting benefits.

Using X2Y for Bypass, Decoupling, and EMI Filtering Components

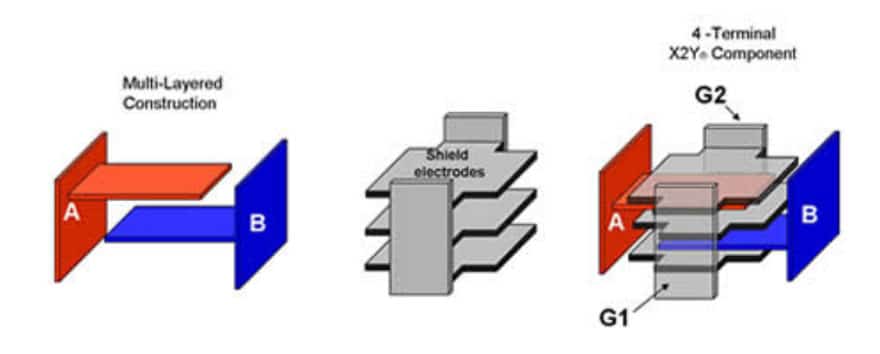

While a traditional bypass capacitor is designed to have stacked opposing electrode layers inside, a bypass capacitor constructed with X2Y incorporates a third set of shield electrode layers. This design effectively surrounds each existing electrode within the stack of the two-terminal capacitor, creating a three-node capacitive circuit as shown in Figure 1. With this design, there are two additional external side terminations, resulting in a four-terminal device.

When using X2Y for bypass or decoupling capacitors, you can achieve ultra-low inductance that provides broadband high-frequency bypassing, which increases circuit performance. Additionally, since this construction requires fewer passive components, system costs are also reduced.

Looking specifically at EMI filters, it’s important to note that filters using an X2Y design are manufactured in the same way as a conventional MLCC but have a special internal architecture that results in ultra-low equivalent series inductance (ESL) through opposing current flows in adjacent parallel plates. These EMI filters are not feedthrough devices, but act as bypass filters, which means they are not current limited since the only signal passing through the chip is the filtered noise to ground. These filters are ideal for twin-line applications such as motors and amplifier inputs, or twisted pair (balanced line) applications where they are fitted between the lines with the center terminal taken to ground.

Additionally, using X2Y for EMI filtering does not add DC resistance, and since two capacitors can be used in a single package, issues with aging, voltage, and temperature variations are eliminated. This means EMI filters constructed with X2Y can offer a dramatic reduction in conducted and radiated noise to meet electro-magnetic compatibility requirements.

Comparing Conventional MLCC Configurations to an X2Y Design

To illustrate some of the benefits described above, let’s look at an amplifier decoupling test performed by X2Y Attenuators, LLC. In the test configurations shown in Figure 2, the company was comparing the noise rejection power of the bypass network of four MLCCs versus the capabilities of just one bypass capacitor designed using X2Y.

As shown in the image of the PCBs used in the experiment in Figure 3, parasitics were equalized and the ground attachment and capacitor setbacks were matched between set-ups.

This test showed that building a conventional filter using two capacitor values per power pin, four capacitors total, resulted in 150 percent the voltage noise versus using just one X2Y capacitor for both power pins. And since a single X2Y ceramic capacitor can be used instead of four conventional MLCCs, circuit designers can drastically reduce their bill of materials (BOM) as well as the size, weight, and cost of the devices they are designing.

Overall, X2Y is an exciting, forward-thinking ceramic capacitor technology. Knowles Precision Devices is not only one of the few manufacturers developing components using this technology, but we also have expert engineers on our team to support designs using X2Y that will help you further reduce the size, weight, and cost of your designs.

Further Background Reference Read: Introduction to EMI Filtering