A higher level of power in smaller parts – this is undoubtedly the overriding direction where the electronic component market is currently heading. This article explains construction and advantage of wide terminal (reverse geometry) resistor chips.

Chip resistors, being one of the smallest and most accessible components in any electronic design. When looking, for instance, at a standard resistor in 1206 case size with a power range of 0.25W, there is a constant demand from the market to achieve this range in a case size not larger than 0603.

For established suppliers of high quality resistors, this means to continuously strive for innovation in order to meet the customers’ demands for a contemporarily advanced resistor portfolio. One of the key approach for meeting those resistor downsizing requirements would be the wide terminal resistors.

Wide Termination Resistors Construction

The name is based on two innovative constructive principles:

- The terminals on this type of resistor are found on the long side of the resistor whereas they are on the short one at conventional products (see Figure 1). So, when having conventionally a 2010 case size, the wide terminal type would be correspondingly 1020 case size. This increases the amount of current being able to pass through the resistor which results in a significantly higher power range.

- Instead of using one block of resistive element, two or three blocks can be used.

Benefits of wide termination designs

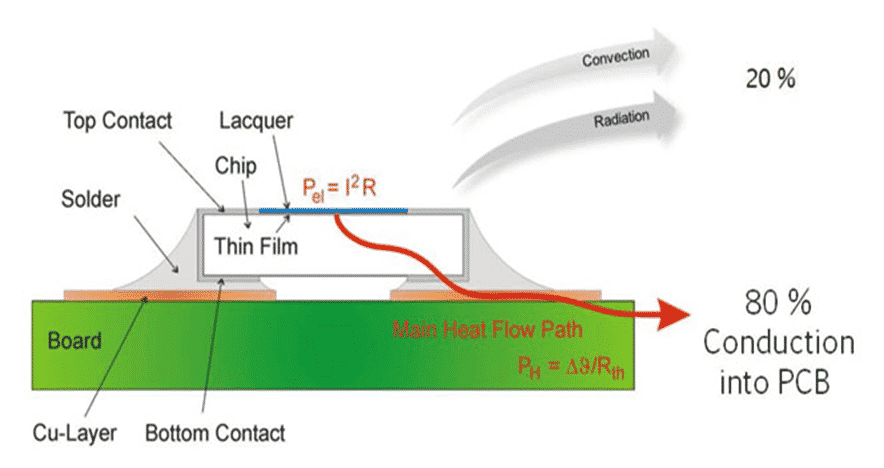

- better thermal conduction into PCB = higher power rating by 30-50% (Figure 2.)

- lower ESL = lower parasitic and higher frequency range (Figure 3.)

- higher mechanical strength = higher vibration and flex stress robustness (Figure 3.)

- less thermal stress as differences in the coefficient of expansion between substrate and chip decreases in significance with shorter distances between terminations

Is there any trade off using reverse geometry wide terminal devices? The only downside of the design, considering the high manufacturing price is now almost identical, that PCB cleaning process may be more difficult in narrow and long gaps between the termination pads.

Using of multiple resistive element blocks

Using of multiple (typically two or three depending to case size) instead of one block of resistive elements may further increase wide termination resistor chips’ thermal dissipation ability and thus increase the power rating even further. Each of these smaller elements is trimmed by laser. This supports the heat dissipation throughout the alumina substrate elements and avoids hotspots in one area. See figure 4.

As a result, the power range can be increased.

Applications

The field of suitable applications for wide terminal resistors is wide: From automotive and industrial applications to building automation and many other applications where a higher power range is as essential as a compact case design.

Wide terminal resistors with lower resistance values are particularly popular for replacing metal shunt resistors. If the replacement is technically feasible, resorting to these resistors helps saving space on the PCB. Wide terminal resistors are much cheaper compared to metal shunt resistors, rendering them the perfect solution for current sensing with higher power requirements.

In the automotive sector, wide terminal resistors can be used in electrical control units (ECU), anti-lock braking systems, headlights, EPS, motors and many other applications whereas in industrial contexts, wide terminal resistors are the perfect solution for power supplies, DC/DC converters or motor controls.

See Figure 5. with example of available types and range.

Summary

Wide terminal, reverse geometry chip resistors present a set of benefits over conventional designs. Electronic designers shall look into these type of components especially when searching for resistor downsizing without any compromises in terms of power handling.

In addition, wide terminal designs provide higher mechanical vibration and flex robustness that is often required in automotive, industrial or aerospace applications. Lower ESL values helps also to improve its operating frequency range.

Use of multiple resistive elements inside of the wide resistor chip body may increase power rating even higher.