This presentation from Würth Elektronik by Andreas Nadle provides an in-depth walkthrough for designing, simulating, and validating 3-phase EMI filters based on real EMC signatures of a device under test (DUT).

Introduction

3-phase AC/DC power conversion is fundamental to modern industrial applications, yet it comes with challenges—particularly electromagnetic interference (EMI) that can degrade system performance and regulatory compliance.

This presentation provides a comprehensive guide to designing, simulating, and validating 3-phase input EMI / EMC filters using state-of-the-art digital tools and real measurement data. Designed for engineers and technical specialists, the article distills essential steps from interference basics through component selection to laboratory validation.

The design of 3-phase EMI filters—filtering both common-mode (CM) and differential-mode (DM) interference—requires a systematic approach that combines theoretical analysis, simulation, and experimental validation.

Key Takeaways

- This article provides a comprehensive guide for designing, simulating, and validating 3-phase EMI filters.

- Key topics include the origins of noise, component selection, and optimization for regulatory compliance.

- It emphasizes the importance of using X and Y capacitors for differential and common mode noise suppression.

- Engineers can utilize digital tools and real measurement data to ensure robust performance.

- The presentation includes practical steps for filter design, testing, and layout considerations.

Chapter 1: Basics of Interference in 3-Phase Systems

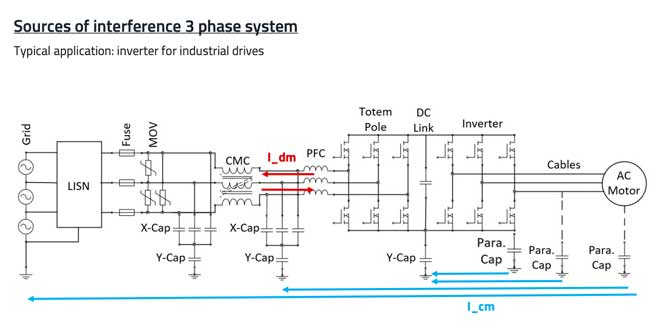

1.1 Differential Mode vs Common Mode Currents

– Differential Mode (DM): Currents follow intended circuit paths, are easier to trace, and generally higher amplitude.

– Common Mode (CM): Currents flow via parasitic paths, affecting unintended circuit segments and are a major source of radiated EMI.

| Mode | Path | Current magnitude | Filtering | Main cause |

|---|---|---|---|---|

| Differential | Within circuit | High | LC, π, T Topology | dI/dt (current switching) |

| Common | Parasitic/earth | Low (µA) | CMC, Y-capacitors | dU/dt (voltage surges) |

1.2 Application Example: Industrial Drives

Inverters for industrial drives are prime examples, with high switching frequencies and power levels that exacerbate EMI concerns.

Chapter 2: Filter Components and Selection

2.1 Safety Capacitors: Y2, X2, MLCC, and Film

Safety capacitors reduce EMI by providing paths for high-frequency currents. Their classification (X2, Y2) dictates voltage, failure mode, and use location.

- X Capacitors: Connected between phases (line-to-line). They suppress differential mode (DM) noise. X1 capacitors are rated for higher surge voltages (up to 5 kV), while X2 capacitors are smaller and cheaper but limited to 2.5 kV surges.

- Y Capacitors: Connected between phase and protective earth. They suppress common mode (CM) noise. Their value is limited by leakage current regulations (typically < 4.7 nF per line in industrial systems).

| Type | Application | Advantages | Limitations |

|---|---|---|---|

| X Capacitors | Phase-to-phase filtering | High surge capability | Larger size, higher cost |

| Y Capacitors | Phase-to-earth filtering | Excellent high-frequency suppression | Leakage current limitations |

Engineers must balance capacitance value, safety ratings, and leakage current. Film capacitors are robust but bulky, while MLCCs (multi-layer ceramic capacitors) offer excellent high-frequency performance but limited capacitance.

- Y2 Capacitors (Phase-to-Protective Earth):

- WCAP-FTY2: Pitch 10–37.5mm, 330VAC, 1nF–1µF, -40°C/+110°C

- WCAP-CSSA (MLCC Y2): SMD 1808–2220, 250VAC, 33pF–4.7nF, -55°C/+125°C

- X2 Capacitors (Phase-to-Phase):

- WCAP-FTX2/FTXX: Pitch 7.5–37.5mm, 310VAC/275VAC, 5.6nF–6.8µF, -40°C/+105°C

- WCAP-FTXH: Pitch 15–37.5mm, 310VAC, 33nF–10µF, up to +110°C, THB 1000h @ 85°C 85%

| Type | Key Series | Volt. (Vrms) | Capacitance Range | Temp. Range |

|---|---|---|---|---|

| Y2 – Film/MLCC | WCAP-FTY2, WCAP-CSSA | 250–330 | 33pF–1µF | -55 to +125°C |

| X2 – Film/MLCC | WCAP-FTX2, FTXH | 275–310 | 5.6nF–10µF | -40 to +110°C |

2.2 Common Mode Chokes (CMCs)

Common mode chokes (CMCs) provide inductance to attenuate CM currents. Their performance depends on core material:

| Core Material | Frequency Range | Advantages | Limitations |

|---|---|---|---|

| Manganese-Zinc Ferrite | Up to ~5 MHz | Good low-frequency attenuation | Limited high-frequency performance |

| Nickel-Zinc Ferrite | 5–30 MHz | Better high-frequency suppression | Lower permeability at low frequencies |

| Nanocrystalline | Broadband (kHz–tens of MHz) | Excellent wideband performance | Higher cost, sensitive to saturation |

Note: Real inductance depends on test frequency; nanocrystalline cores show substantial drop-off above 100kHz.

- MnZn ferrite core: 1–24A, 0.52mH–12mH, 1kHz–2MHz frequency range (e.g., WE-TPB, Ø47mm)

- Nanocrystalline core: 20–46A, up to 208mH, 1kHz–20MHz (e.g., WE-TPBHV, Ø70mm)

- Frequency Response: Nanocrystalline offers better performance above 1MHz, but with core nonlinearity and specific derating at higher frequencies.

| Core Material | Current (A) | Inductance (mH) | Freq. Range (kHz) | Example Series |

|---|---|---|---|---|

| MnZn | to 24 | 0.52-12 | 1–2000 | WE-TPB |

| Nanocrystalline | to 46 | 0.2–208 | 1–20000 | WE-TPBHV |

2.3 Surge Protection Varistors

Varistors protect against voltage surges. Selection is based on voltage class, current capacity, certified reliability.

- WE-VD Series: 5–20mm diameter, 14V–1000V RMS, 100A–10,000A, -40°C to +105°C, certified by UL/IEC/VDE.

2.4 Component Selection Example: Lab Device Under Test (DUT)

- Filter for 4kW inverter drive, 5A, 400V 3-phase grid

- Combination: Y2 MLCC caps, X2 film caps, nanocrystalline CMC, WE-VD varistor

Chapter 3: Filter Topology, Calculation and Simulation

3.1 Detailed Filter Structures

CM and DM Filtering Structure:

- CM (Common Mode): LC topology (CMC + large Y-capacitor)

- DM (Differential Mode): CLC π topology (3 x X2 between each phase, 2 x series CMCs)

- High-frequency suppression: 3x small MLCC Y2-caps between each phase and PE supplement the main Y-cap

| Functional Block | Main Parts | Purpose |

|---|---|---|

| CM Filter | CMC + large Y-cap | Suppress parasitic return-path currents |

| DM Filter | X2 film caps + series CMCs | Smooth line-to-line switching noise |

| Surge Protection | Varistor (WE-VD) | Clamp surges, protect filter/downgrid |

3.2 Component Sizing and Calculations

Key variables:

– fc = corner frequency

– Ldm, Lcm = DM/CM inductance

– Cx, Cy = interphase and PE capacitance

– Required attenuation = 60dB at 200kHz as specified by CISPR B

Effective X2 Capacitance (Cx) Between Phases:

C xeff = 1 1Cx1 + 1Cx2Effective Y2 Capacitance (Cy), phase-to-PE:

C yeff = ( 1Cy1 + 1Cy2 + 1Cy3 + 1Cy4 ) –1Corner Frequency (DM or CM):

f cdm/cm = 1 2 π L CRequired Attenuation for Desired Frequency at 1-stage LC:

A fsw = log fsw / f co ⋅ 40 dBRequired Attenuation for Desired Frequency at 2-stage LC:

A fsw = log fsw / f co ⋅ 80 dBCLC Filter PI Attenuation:

A fsw = log fsw / f co ⋅ 60 dBAttenuation:

For DM CLC: 60dB/dec

For CM LC: 40dB/dec

Example Sizing (referenced):

– fc_dm = 20kHz (DM), fc_cm = 6.3kHz (CM)

– Cx = 4.7µF x 6, Cy = 47nF, Lcm = 8.4mH, Ldm ≈ 62µH

3.3 Simulation – Practical Details

- LTspice used for transfer function analysis (frequency-dependent insertion loss)

- Cores exhibit non-linear impedance: E.g., 8mH @10kHz, ~5mH @100kHz for nanocrystalline cores

- Verify physical layout in Altium: PCB shows capacitors and CMC placement, improved PE paths

Chapter 4: Test Setup and Practical Measurements

4.1 Laboratory Measurement Configuration

- Standard LISN (Line Impedance Stabilization Network) as per CISPR 16, 3-phase version

- Test device: 4kW inverter fed by 400V 3-phase, driving a 5A motor load (fan)

- Test setup incorporates LISN, inverter + EMC filter, and realistic load

- Test frequency range: 150kHz to 30MHz

4.2 EMI Measurement Results

| Configuration | Measured EMI (dBµV) | Comment |

|---|---|---|

| No Filter | 115 | Well above Class B limit (65 dBµV QP) |

| Filter, Correct Ycap Placement | ~55 | Passes; 60dB attenuation @200kHz |

| Filter, Ycap Misplacement | ~>65 | Fails; Misplacement reduces performance |

- DM noise dominates below 50kHz, CM above 100kHz

- Correct Y-capacitor position is critical for high-frequency attenuation

- Measurement probes compare total CM vs DM noise for full compliance validation

Chapter 5: PCB Design, Manufacturing, and Optimization

5.1 PCB Layout & Mechanical Considerations

- Use 4-layer PCBs with separated high-current and signal layers for best EMC

- Ensure low impedance path from PE to chassis; improve ground plane connectivity

- Air and creepage distances must comply—especially when using MLCC Y capacitors

- Compact layout helps minimize parasitic couplings and optimizes cooling

5.2 Troubleshooting and Field Failures

- Improper placement of filter components (Ycaps, CMC) can negate up to 40dB attenuation

- Varistor failure: always verify with high-energy test pulses as per IEC/UL

- Frequency response of CMC may lead to excessive EMI above 1–2MHz—redesign or parallel chokes as remedy

5.3 Recommendations and Final Optimization Steps

- Use simulation to predict worst-case—verify with real EMI data

- Select capacitors with stress test data (THB, temperature cycling, surge)

- Document and peer-review PCB layout for high-voltage safety

- Iterate design as new EMI problems emerge in the field

Conclusion

A modern 3-phase input EMI filter must be engineered with deep understanding of system interference sources, smart component selection, and rigorous verification via simulation and measurement. The combined approach outlined here delivers robust designs that meet stringent EMC standards in real-world industrial environments.

FAQ: 3-Phase EMI Filter Design & Simulation

X capacitors are used between phases to suppress differential mode noise, while Y capacitors connect between phase and earth to suppress common mode noise. Both are essential for comprehensive EMI filtering.

Common mode chokes attenuate currents returning through protective earth. Their performance depends on core material, with nanocrystalline cores offering wideband suppression and ferrites providing targeted frequency attenuation.

Differential mode interference flows between phase conductors, while common mode interference returns through protective earth. Each requires different filtering strategies.

LTSpice allows engineers to simulate both differential and common mode noise paths using LISN impedance models. This predicts insertion loss and ensures the filter meets EMC requirements before physical prototyping.

Critical practices include placing Y capacitors close to the noise source, using wide copper planes for grounding, minimizing parasitic inductance, and considering multi-stage filters for improved high-frequency performance.

PCB layout is critical. Incorrect placement of Y capacitors or poor grounding can reduce attenuation by tens of decibels.

How-to: Design and Validate a 3-Phase EMI Filter

- Measure Baseline EMI

Perform initial measurements without filters to determine the required attenuation margin.

- Select Capacitors

Choose X capacitors for differential mode suppression and Y capacitors for common mode suppression, balancing capacitance, leakage current, and surge ratings.

- Choose Common Mode Choke

Select choke material based on frequency range. Manganese-zinc ferrites are effective at low frequencies, while nanocrystalline cores provide wideband performance.

- Simulate in LTSpice

Model DM and CM paths using LISN impedance values. Ensure simulated insertion loss meets or exceeds 60 dB at critical frequencies.

- Validate in EMC Laboratory

Test the filter across 150 kHz–30 MHz using a certified chamber and LISN setup. Compare results with simulation data.

- Optimize PCB Layout

Place Y capacitors near the noise source, minimize trace lengths, and use direct grounding paths. Consider multi-stage filters for enhanced performance.

- Finalize Design

Adjust component values or add stages if necessary. Ensure compliance with EMC standards and robustness under real-world operating conditions.