This article is written by Vladimir Azbel Ph.D., semiconductor process reliability engineer consultant, Israel, who investigates how tantalum anode heat treatment impact capacitance and DCL leakage current of tantalum capacitors.

Introduction

It is known that the process of formation of a sintered pellet, leading to the creation of amorphous Ta2O5, is accompanied by internal stresses in the anode caused by the difference in the thermal expansion coefficients of Ta and Ta2O5.

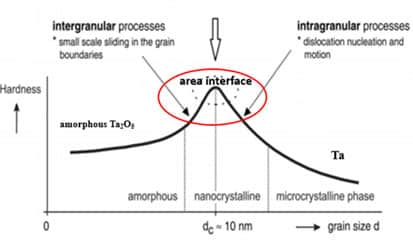

The most critical area is the concentration of these stresses, located between Ta and the amorphous Ta2O5 film, which is clearly illustrated in the diagram presented in Figure 1a.

This diagram is used to explain the experimental results (Figure 1b) obtained as part of the study /1 / Tantalum Capacitor DCL & Life-Time Prediction by Evaluation of Anode Mechanical Properties.

The model explains how internal stresses of such a sandwich are dependent to the anode manufacturing technological process.

The presence of these stresses increases the risk of aging of the anode during its subsequent movement through the technological process.

The impact of the technological process is mainly determined by temperature and ambient, which are the source of the aging process and, as a consequence, the degradation of its leakage currents (DCL). It should be noted that the size of the zone, as well as the stresses in it, depends on the anode recipe /2 /

Tantalum Capacitor Anode Heat Treatment Impact to Mechanical and Electrical Properties

To ensure the stability of the anode structure, a number of manufacturers I have worked with subject the finished anode to additional heat treatment in various ambient such as air, nitrogen, and vacuum. During the aging process in the anode, changes occur in the microstructure and, consequently, in its properties. These changes affect its electrical and mechanical characteristics. /3 /

Today, the criterion for assessing the acceptability of the selected conditions for heat treatment of the finished anode is, if not achieving an improvement, then at least maintaining the value of Capacitorance (CAP) and Leakage current (DCL) before and after heat treatment. To what extent this criterion guarantees a reduction in the risk of anode aging, we will consider further in the following experiment.

Experiment

For the experiment, anodes made from 150 kCV/g powder, with a pressing density of 5.75 g/cc and sintered at a temperature of 1260°C for 20 minutes, and then formation at 8V, were used. The finished anodes were heat treated at 450°C in three different ambient: air, nitrogen, and vacuum. It is important to note that a temperature of 450°C is the upper limit for heat treatment of the anode in an ambient air, since above this temperature the amorphous tantalum oxide film begins to crystallize.

In the case of vacuum ambient processing, this process begins at temperatures above 700°C. This temperature range makes it possible to achieve the maximum rate of oxygen diffusion, which is considered a key factor in the anode aging process, because its diffusion is directed in the area of internal stresses, for their relaxation.

Electrical and mechanical characteristics were measured on the anodes before and after heat treatment in different atmospheres. It is important to note that the measurements were taken before the reformation stage, which is critical for electrical performance analysis and has almost no effect on mechanical properties as verified experimentally. In Fig.2, the influence of the atmosphere on CAP, DCL, and oxygen content is shown.

Results & Discussions

From the results of the experiments, the following conclusions can be made on CAP and DCL dependency on the atmosphere and temperature:

- Vacuum heat treatment has a significant effect on CAP and DCL compared to before heat treatment, but does not affect oxygen content.

- Heat treatment in air leads to a decrease in CAP and an increase in DCL and oxygen content compared to the state before heat treatment. However, DCL values remain significantly lower than with vacuum heat treatment.

It is interesting to note that vacuum pre-heat treatment followed by air heat treatment results in CAP, DCL, and oxygen content values that are not significantly different from those obtained with air heat treatment.

The effect of the atmosphere on the mechanical properties of the anode at 450°C, such as yield strength (AY) and tensile strength (AUTS), is shown in Figure 3. Also shown in this figure are the CAP, DCL/CV, and oxygen content (O2) values for those the same anodes obtained before mechanical testing to facilitate analysis.

From the data presented in Fig. 3, the following conclusions can be drawn about the influence of the atmosphere on the mechanical and electrical parameters of the material after heat treatment at a temperature of 450°C:

- Heat treatment in ambient air:

- Leads to the reduction in AUTS strength.

- Leads to degeneration of Ae.

- Increases oxygen content due to its diffusion from the air.

- Degeneracy of Ae indicates loss of plasticity due to the formation of crystalline Ta2O5, as a result of oxygen diffusion into the interface zone

- Heat treatment in vacuum:

- Also leads to a decrease in Ae and AUTS, but with a constant oxygen content.

- Indicates a decrease in internal stress, probably due to restructuring of the structure without external access to oxygen.

Consequently, heat treatment in a protective atmosphere does not lead to the relaxation of internal stresses in the anode, which does not guarantee the preservation of the stability of the anode structure, in the production of tantalum capacitor

Reasons leading to the influence of the atmosphere on the CAP and DCL.

- The ambient of air is an oxygen ambient. The diffusion of oxygen into the area of internal stress in the volume of the anode leads to oxidation, with the creation of crystalline Ta2O5, which is reflected, not only, in a decrease in mechanical properties, but and CAP. The decrease in CAP, according to the work of Yu. Freeman-Pozdeev /4 / is due to the creation of crystalline oxide at the boundary between Ta and amorphous Ta2O5. According to Fig.1, this is probably due to the high internal stresses formed during formation in the interface zone, when instead of a nanocrystalline structure, crystalline Ta2O5 is formed.

- Vacuum ambient: when heat treated in a vacuum, due to the lack of free oxygen, in the presence of tension in the interface zone, in an amorphous film, at the interface between Ta and the film, elastic tensile stresses arise in the latter, which leads to an increase in the dielectric constant and an increase in the CAP, and on the other hand, this leads to a loss of dielectric properties and the growth of DCL. This process allows us to understand the reduction in mechanical characteristics.

- Nitrogen ambient: heat treatment in an inert nitrogen ambient, as well as in a vacuum, prevents oxidation in the anode. Changes in CAP and DCL are of a similar vacuum, but the values are smaller, which is probably due to the low purity of nitrogen and less protection from the external environment. At the same time, the values of the mechanical characteristics are practically the same.

Subsequent reformation led to the recovery of CAP and DCL of the anode, for nitrogen and vacuum, which probably gave out as the basis for considering such heat treatments acceptable.

In this case, the mechanical characteristics practically do not change, despite the diffusion of oxygen at the reformation process, which is probably due to the initial use of oxygen to heal the amorphous film, which becomes an anti-diffusion barrier for diffusion of oxygen.

To stabilize the properties of the anode, for the subsequent technological process and reduce the risk of DСL degradation during the operation of the heating complex, it is recommended to use heat treatment of the anode at 450C, in an ambient air, with parallel control of the mechanical characteristics.

If the mechanical characteristics of the anode deviate by more than 5-10 %, after heat treatment in the ambient air, it is not recommended to use this anode for further use in production. / 5 /

Conclusion

- An approach is proposed for the quantitative assessment of internal stresses in the volume of the anode, based on its mechanical characteristics.

- Internal stresses in the anode can be determined through the diffusion of free oxygen within the anode volume during its heat treatment process. This process is accompanied by an increase in oxygen concentration compared to the initial state before heat treatment.

- The presence of free oxygen within the anode is a result of the heat treatment process conducted in ambient air.

- To estimate residual stresses in the anode and its suitability for use in capacitor production, a key quantitative indicator is the difference in the yield strength before and after heat treatment.

References

- Nanocomposite Thin Films for both Mechanical and Functional Applications; SAM ZHANG, co-au.

- Anode Acceptability Evaluation Method of Tantalum Capacitor V. Azbel on LinkedIn

- Reducing the implementation time of tantalum powders in capacitor production. V. Azbel on LinkedIn

- Effect of Dissolved Oxygen on Thermal Oxidation in Ta2O5/Ta Sandwiches YU. POZDEEV-FREEMAN, co-au. Journal of Electronic Materials, Vol. 27, No. 9, 1998

- Mechanical stress of anodized pellet predicts the Ta-capacitor reliability V. Azbel on LinkedIn

- Tantalum Capacitors Reliability, Leakage Current Stability Prediction and Cost Reduction by Anode Characterization During Manufacturing Process; Vladimir Azbel 3rd PCNS Passive Components Networking Symposium 7 – 10TH SEPTEMBER 2021, MILANO, ITALY

Acknowledgement

I would like to express my gratitude to T. Zednicek for the idea of writing this article and for his advice.