The paper “A New Approach to the Design of High Precision Integrated Resistive Voltage Dividers” was presented by Stephen Oxley, TT Electronics, Bedlington, UK at the 5th PCNS Passive Components Networking Symposium 9-12th September 2025, Seville, Spain as paper No. 3.3.

Introduction

This article presents a new methodology for designing high precision integrated resistive voltage dividers capable of handling high voltages without the prohibitive costs and complexity of conventional precision enhancement techniques.

Traditional designs rely on two resistive elements on a single substrate, but when high voltage requirements are added, maintaining low temperature and voltage coefficients becomes challenging.

The proposed approach, called the Cascaded Balanced Divider (CBD), leverages multi-stage balanced resistor networks to achieve superior precision using standard thick film materials and processes.

Key Points

- Conventional two-element dividers struggle with high voltage applications due to mismatched TCRs, VCRs, and long-term drift.

- Existing mitigation strategies involve improved materials, direct-write processes, or component matching and joining—each with cost and yield penalties.

- The new CBD design uses multiple cascaded stages of identical resistor elements to distribute voltage, reduce sensitivity to inter-stage mismatch, and achieve high precision.

- Initial test results show that CBD achieves TCVR and VCVR comparable to or better than top-performing conventional dividers without special manufacturing processes.

- Future work will focus on AC performance, trimming strategies, optimized layouts, and life stability under load.

Extended Summary

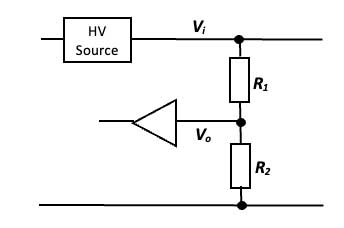

Conventional high voltage resistive dividers are comprised of a high voltage leg (R1) and a low voltage leg (R2), and the voltage division ratio depends on the ratio of these resistances. Achieving ratios in the hundreds or thousands introduces challenges in thick film technologies, which inherently have higher TCRs and are less stable than metal film technologies. Manufacturers have attempted to improve accuracy through material improvements, direct-write fabrication, and component matching. While effective, these methods increase cost and complexity.

To address these limitations, the paper introduces the Cascaded Balanced Divider (CBD) concept. Borrowing from the principles of the Kelvin Varley circuit, CBD divides the high voltage in multiple stages, each built from identical resistor elements arranged to form balanced ratios. By cascading these stages, the overall voltage ratio approximates the product of the stage ratios, while in-stage matching maintains high precision. Inter-stage variations in TCR or drift have minimal impact due to the design’s intrinsic insensitivity to these factors, assuming inter-stage loading is controlled.

Simulation and experimental results support the CBD approach. A two-stage 196:1 prototype achieved TCVR better than ±5 ppm/°C and VCVR around −0.2 ppm/V, demonstrating that ratio error is significantly lower than the absolute error of individual resistors. The paper also outlines layout and manufacturing considerations, such as aligning identical elements, using standard thick film inks, and minimizing fine trimming in the high voltage stages to preserve stability. Test results indicate that CBD dividers can meet or exceed the precision of top-tier conventional dividers without resorting to expensive matching or specialized processes.

Future improvements will focus on AC performance characterization, implementing coarse and fine trimming strategies, optimizing layouts for reduced power density and voltage stress, and conducting long-term drift studies under different load conditions. These steps aim to validate CBD as a cost-effective, high-performance solution for applications like energy metering, electric vehicles, and medical devices.

Conclusion

The Cascaded Balanced Divider method presents a significant advancement in high precision high voltage divider design. By leveraging cascaded multi-element stages, the approach achieves superior temperature and voltage stability using standard thick film processes, eliminating the need for costly matching or specialized fabrication. Initial prototypes confirm improved stability and pave the way for practical, manufacturable products suitable for a wide range of demanding applications.