Mixing a trace of an additional element into a BaTiO3 MLCC class II dielectric material used in electronics could dramatically improve the material’s properties and increase of energy density.

The performance of a capacitor, a component that is essential to nearly every electronic device, depends in part on the amount of energy that the material between the capacitor’s plates can store. Preliminary results presented at the Fundamental Physics of Ferroelectrics and Related Materials conference held last month in Silver Spring, Maryland, suggest a new way of optimizing this energy storage capacity. Researchers showed that by replacing some of the intrinsic atoms in a crystal with atoms of a different element, they could generate an additional electric field inside the material that boosted the energy storage by 50%.

A voltage applied across the plates of a capacitor produces an electric field in the thin layer of material between the plates. The stronger the field produced for a given voltage, the more energy the field can store, and the more efficient the capacitor. So high energy storage capacity is an important goal for the material in a capacitor.

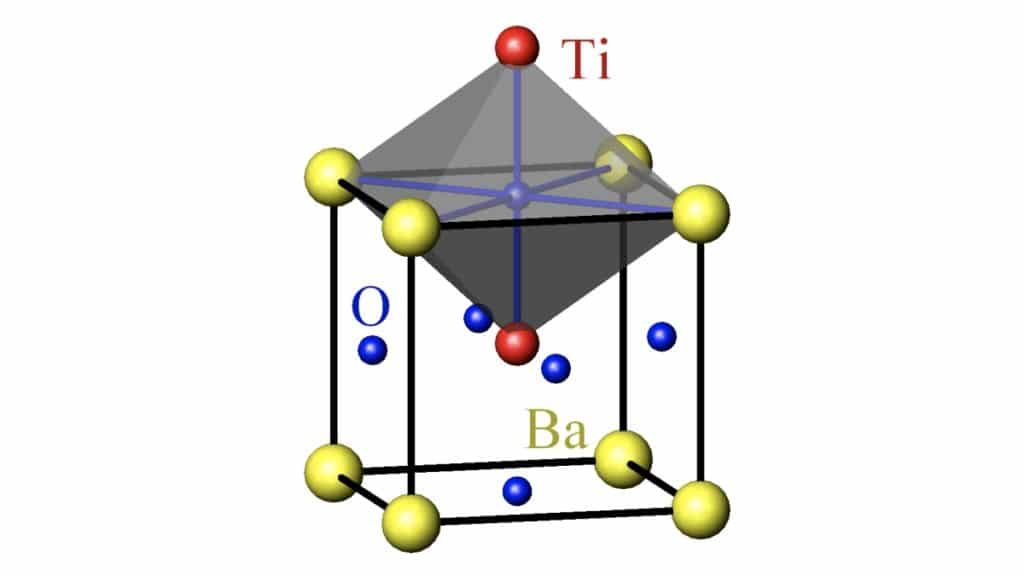

A ferroelectric material, a common choice to fill capacitors, is analogous to a ferromagnetic material like iron, except that it produces electric fields. Inside a ferroelectric, molecular-scale electric dipoles interact and point in the same direction, as long as the system is below the ferroelectric transition temperature. If an external electric field is applied, the dipoles can collectively align with it.

Researchers have previously shown that if you replace a small fraction of the titanium atoms in barium titanate (a ferroelectric) with atoms of another metal, then so-called defect dipoles form. Each of these new dipoles is composed of a replacement metal atom paired with a neighboring oxygen vacancy. These dipoles are too far apart to spontaneously align with one another, but they can still align with an external electric field. However, they require high temperatures or long times to do so because the oxygen vacancy has to “jump” from one site to another around the metal atom in order to change the dipole orientation. In contrast, each intrinsic dipole changes orientation more easily, through small shifts in atomic positions in the crystal lattice.

Researchers have previously observed the effects of defect dipoles but had not tried to optimize them to improve specific material properties for use in devices. To improve energy storage in barium titanate, Pierre-Eymeric Janolin of Paris-Saclay University and his graduate student Zechau Li replaced 0.4% of the titanium with copper. They heated the modified material to about 200 °C and held it in a strong electric field (up to 23 kV/cm) for two hours to align the defect dipoles. Then they cooled it below the ferroelectric transition temperature of about 125 °C. At this temperature, the defect dipoles remained fixed and provided a constant, “baked-in” field that increased the energy storage density by up to 50%, Janolin reported at the meeting.

The results Janolin presented are based on the first set of experiments, which used barium titanate because it’s a standard ferroelectric. Janolin says that he and Li were “very surprised to see that on a model material and without much effort” they were able to improve the energy storage density so dramatically. He says there is still a long list of tests to carry out in order to verify the results, and he’s hopeful that they will be able to improve energy storage even more.

The duo is also using defect dipoles to modify other properties of ferroelectrics, such as piezoelectricity—the ability to expand or contract in response to a voltage—which is exploited in products such as microphones, transducers, and actuators. Their long-term goal is to learn how to control the properties of barium titanate and related materials in order to improve their performance in devices.