What is the UL94 flammability test that are referred by number of manufacturers using plastic polymer materials such as moulding packages? Omnexus, the material selection platform for plastic material by SpecialChem provides an overview of the test in details.

Preliminary Screening of Plastic Polymer Materials for Fire Performance

UL 94 (Underwriters Laboratories test standard UL 94) is one of the most widely used flammability tests for determining relative flammability for plastic materials. It measures the ability of plastic part to extinguish the flame after ignition and its dripping behavior in response to a small open flame or radiant heat source under controlled laboratory conditions.

The tests results are intended to serve as a preliminary indication of the material’s suitability with respect to flammability for a particular application, such as plastic materials used for parts in electronic devices and appliances.

The flammability is influenced by several factors such as:

- Ease of ignition – how rapidly a material ignites

- Flame spread – how rapidly fire spreads across a polymer surface

- Fire endurance – how rapidly fire penetrates a wall or barrier

- Rate of heat release – how much heat is released and how quickly

- Ease of extinction – how rapidly the flame chemistry leads to extinction

- Smoke evolution

- Toxic gas generation

Hence, the study of how plastics burn has been, and continues to be, a major area of research to examine:

- The nature of the burning phenomenon in plastics

- Various methods to reduce plastics flammability, and

- Methods to test flammability

Main Types of Testing & Flammability Ratings to Classify Plastics

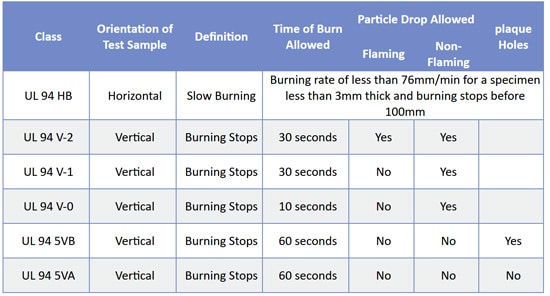

The UL standard classifies plastics according to the minimum thickness at which it stops burning when tested in a horizontal or vertical orientation.

Types of testing/flammability ratings covered in the UL 94 standard for flammability of plastic materials include:

- Vertical burning tests (V-0, V-1, V-2, 5V, 5VA, 5VB, VTM-0, VTM-1, VTM-2)

- Horizontal burning tests (HB, HBF, HF-1, HF-2)

(Source: W. L. Gore & Associates, Inc.)

The UL test methods are aligned with IEC 60707, IEC 60695-11-10, IEC 60695-11-20, ISO 9772 and ISO 9773 standards used to determine fire properties.

Vertical Burning Test for Classifying Materials

UL 94 V Rating: V-0, V-1, V-2

This test measures the self-extinguishing time of the vertically oriented polymer specimen. The top of the test specimen is clamped to a stand and the burner is placed directly below the specimen. The test evaluates both the burning and afterglow times and dripping of the burning test specimen.

The material will be rated:

- V-0: if flame extinguishes within 10 seconds with no dripping

- V1: if flame extinguishes within 30 seconds with no dripping

- V2: if flame extinguishes within 10 seconds with dripping

| Flammability rating UL 94 V | |||

| Test Criteria | V-0 | V-1 | V-2 |

| Burning time of each individual test specimen (s) (after first and second flame applications) | ≤10 | ≤30 | ≤30 |

| Total burning time (s) (10 flame applications) | ≤50 | ≤250 | ≤250 |

| Burning and afterglow times after second flame application (s) | ≤30 | ≤60 | ≤60 |

| Dripping of burning specimens (ignition of cotton batting) | no | no | yes |

| Combustion up to holding clamp (specimens completely burned) | no | no | no |

(Source : UL LLC)

UL 94 VTM Rating: VTM-0, VTM-1 and VTM-2 – Thin Material Vertical Burning Testing

This test method is used for thin specimen or materials that are too flexible or may distort, shrink or flex during the traditional vertical testing (failure to pass the UL 94 V test is a precondition of all VTM ratings). This test is similar to the vertical burning test except that the material is wrapped around a mandrel before clamping to the stand and the flame application is reduced. In this test, the flame is applied only for 3 seconds.

| Flammability rating UL 94 VTM | |||

| Test Criteria | VTM-0 | VTM-1 | VTM-2 |

| Burning time of each individual test specimen (s) (after first and second flame applications) | ≤10 | ≤30 | ≤30 |

| Total burning time (s) (10 flame applications) | ≤50 | ≤250 | ≤250 |

| Burning and afterglow times after second flame application (s) | ≤30 | ≤60 | ≤60 |

| Dripping of burning specimens (ignition of cotton batting) | no | no | yes |

| Combustion up to holding clamp (specimens completely burned) | no | no | no |

(Source : UL LLC)

UL 94 5V Rating: 5V, 5VA, 5VB – Vertical Testing is done on both bar and plaque specimens

For any material to achieve 5V classification, the test specimens must not burn with flaming and/or glowing combustion for more than 60 sec after the fifth flame. Also, the test specimens must not drip.

| Flammability rating UL 94 | ||

| Test Criteria | 5VA | 5VB |

| Burning and afterglow times of specimens after fifth flame application (s) | ≤60 | ≤60 |

| Dripping of burning specimens | no | no |

| Hole formation | no | yes |

(Source : UL LLC)

Horizontal Burning Test for Classifying Material

Specimens molded from the plastic material are oriented in either a horizontal depending on the specifications of the relevant test method, and they are subjected to a defined flame ignition source for a specified period of time.

UL 94 HB Rating

A material having a thickness between 3 and 13mm will be classified as a HB material if it does not have a burning rate exceeding 40mm per minute. For material with thickness less than 3mm the burning rate should not exceed 75mm per minute. The material will also be rated as HB if it ceases to burn before the 100mm mark independent of thickness.

| Test criteria | Burning rate in V | Flammability rating |

| Test specimen thickness 3-13mm | ≤40 mm/min | HB |

| Test specimen thickness < 3 | ≤75 mm/min | HB |

| Flame is extinguished before first mark | ≡ 0 mm/min | HB |

(Source: UL LLC)

UL 94 HBF: HBF, HF-1 and HF-2 – Horizontal Burning Foamed Material

This test grants three different types of ratings depending on burning rates and or after flame times. A material will be classified as a HBF material if it does not have a burning rate exceeding 40mm per minute over a 100 mm span or if ceases to burn before flaming or glowing reach the 125mm mark.

| Flammability rating UL 94 HBF | ||

| Test criteria (test specimens) | HF-1 | HF-2 |

| Burning time (s) | 4/5 ≤ 2 1/5 ≤ 10 | 4/5 ≤ 2 1/5 ≤ 10 |

| Burning and afterglow time of each individual specimen (s) | ≤ 30 | ≤ 30 |

| Dripping of burning specimen (ignition of cotton batting) | no | yes |

| Damaged length of individual specimen (mm) | < 60 | < 60 |

(Source: UL LLC)