Source: 3DPrint.com article

by Joris Peels. Recently 3DPrint.com published an article about 3DInductors. This is a new service that lets you 3D print pure copper induction coils. 3DInductors was developed by GH Induction which is a part of GH Group, based in Valencia Spain and one of the market leaders in induction heating.

The company developed its own technology application for 3D printing copper based on EBM (Electron Beam Welding). This is a complex process to work with and dial in for manufacturing. In addition, copper 3D printing has been attempted before by many players only for them to find out that it is much more difficult than they think. Of the players that say that say can do it right now precious few are actually able to deliver parts at scale.

What’s more, the 3DInductors team is the first to do this for EBM. Also, it is the first company able to 3D print pure copper. It’s incredibly innovative that the GH Group would go through the significant lengths to develop their own technology and then to launch a direct to customer “start up/separate brand/skunkworks” type of play to bring it to market. I think that this really shows a very fruitful path for staid and large companies to innovate.

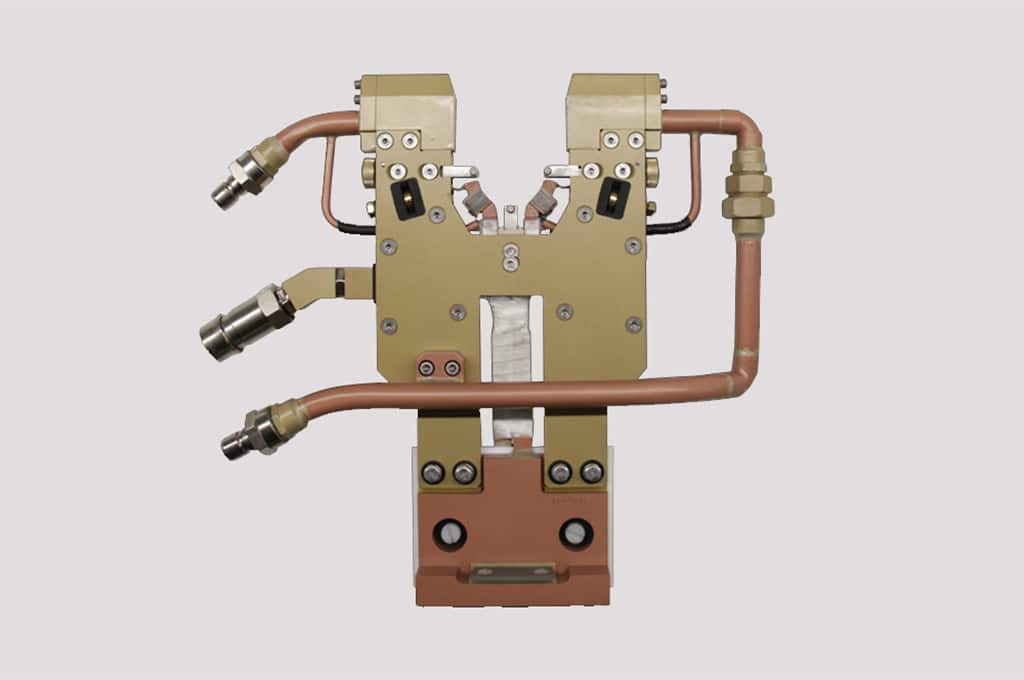

A 3D Printed Pure Copper Induction Coil

Induction coils are used to heat conductive metals in order to harden them via induction heating. Traditionally they were made by hand but the design freedom was limited. With 3DCoil 3DInductors opens up the design space for these parts. Lower inventory and lower TCO are just some of the benefits. A very exciting thing, however, is that due to the 3D printing process the parts last up to four times longer than the traditionally made ones. The combination of these factors may see the induction heating industry forever changed.

The company uses 99.99% copper and has a very high 99.7% recycling rate. They’ve already shipped over 400 of these 3D printed coils to customers including large automotive firms such as Renault. They also 3D print quenches to go with your induction coils. The business case for this looks very solid indeed and I love innovation such as this. We reached out to the firm with more questions and Concepción (do call her Inma) Sánchez was kind enough to answer them.

Why did you turn to 3D printing?

In induction metal parts heating, coils and inductors are the core of the process. They are the end tool where the magnetic process affecting the part, or material to be heated, occurs.

After more than a century in which the dominant manufacturing process has been mainly based, upon joining technologies such as brazing or soldering, skilled coppersmithing has been the safeguard of the quality with unique knowledge and know-how. The use of fixtures, mandrels, and machined parts has improved the repeatability and quality of the produced elements but high volume, dimensional repeatability has always been a source of problems.

All manufacturers are working continuously on the improvement of such relatively artisanal methods to allow better lifetime, minimized production time and overall better quality.

GH Induction is always looking for new technologies that benefit directly to our customers. This is our main added value.

Why copper?

The raw material for inductors is copper because it is the ideal for induction heat treatment in metal parts.

Copper represents the best compromise between electrical conductivity, mechanical properties, and cost. Other material could be used but either do not match cost limitation or mechanical properties.

Was it difficult to develop a copper process?

It really was.

GH Induction performed tests and developments with the available technologies before taking a decision on LBM (Laser Beam Melting) or EBM (Electron Beam Melting). We obtained better results (melting rate, porosity level) with EBM while using copper powder than with LBM (beam reflection problem, Argon trapped). In addition, considering an industrial production approach, the EBM technology allows to stack parts one above the other.

Then we had to develop from scratch EBM with pure copper manufacturing method. That didn’t exist before with EBM (Electron Beam Melting) printing technology.

Only titanium and cobalt-chrome printing for demanding applications in mechanical properties like orthopedic implants and aerospace parts were developed so far.

GH Induction together with a research center took some years to develop the process with pure copper material.

The solution was so innovative that we have been able to patent it. We are working with it for 5 years now and we commercialize it for almost 3 years now.

It is a breakthrough in the industrial induction heating sector.

What machines do you run it on?

We have several machines, all based upon Electron Beam Melting technology which utilize a high power electron beam that generates the energy needed for high melting capacity and high productivity. The electron beam is managed by electromagnetic coils providing extremely fast and accurate beam control that allows several melt pools to be maintained simultaneously (MultiBeam).

The process takes place in vacuum and at high temperature, resulting in stress relieved components with material properties better than cast and comparable to forged material. Our method based on EBM is the only 3D printing method able to print pure copper.

The service life is much longer, the density is higher minimizing leakages and the mechanical and electrical properties are better. LBM techniques use copper alloys and they present intrinsic drawback when considering the manufacturing of coil with pure copper:

- Limited transformation of the energy into efficient melting due to the refraction of the beam on copper

- Post treatment needed due to created stress within the part

- Risk of pollution of the element (no vacuum)

- Use of an additional element to improve powder bonding remains as one important question mark.

Do you use pure copper? Other materials?

Only pure copper at the moment but we are always researching.

Copper alloys are not suitable because the alloy elements must be removed in order to avoid rusting creation of inclusion or compound which makes the manufacturing process more complex.

What are the advantages of 3D printing copper for your parts?

The inductor is an end effector where take place the creation of the magnetic field required for the induction heating effect. That means it follows the contour of the part we want to heat. The advantage of printing copper is that we can manage complex design that before were extremely or impossible to do with a more classical method (brazed elements).

In addition, we translate directly into the printer the CAD deign we have engineered. It includes shape changes that we believe allow to obtain the best efficiency in terms of pattern and magnetic precision.

We should not forget that an inductor is a tube shaped into the form we want to give it. Tubular section variation is needed since high power density flows onto the surface and requires cooling in most cases and we are in the vicinity of a part which can top at more than 1000 deg C.

Another aspect of that technology is the high reproducibility which allows the end-user to swap inductors with no or limited setting. That brings a clear gain in time.

How does 3D printing extend the service life of the components?

The traditional method to manufacture copper coils is to join empty copper tubes segments by brazing. These coils must be cooled to withstand the high currency flowing through them. Mechanical fatigue results with the contraction and retraction cycles due to the magnetic forces onto the copper surface during the heating phases. Then the brazed joints in a coil/inductor assembly are often the weakest points and the initiation point of the coil destruction. Using 3D printing the coil is created as a single 3D piece without brazed joints increasing dramatically the lifespan.

We have seen improvements of over 400%. However, we see an average increase higher than 100% in most cases

In addition, the design is modelled through the 3D CAD software optimizing both outer and inner design:

- reducing the points with higher current density (hot spots)

- improving coil cooling by changing the geometric characteristics of the inductors

- Manufacturing process carried out in a vacuum atmosphere in order to avoid porosity and rusting.

- High dimensional accuracy process that allows identical coil copies.

- These inductors can be repaired just like the traditional ones.

How many parts do you make?

We have already hundreds of 3D inductors in-field. Depending on the induction application, meaning type of part to heat and process, we can reach different results but always better. For instance, in an automotive driveline case we get 400% more lifespan.

Imagine the operational savings for the customer:

- Dramatic decrease of their part production cost

- Extreme reduction of production stoppages

- Less inventory

How does geometric freedom help your part performance?

There are cases where the main benefit is the ability of adaptation to the part to be heated. In these cases the conventional brazed coils for mechanical reasons cannot fit to the part for optimum heat treatment. Another big benefit is the capability to improve continuously an original coil design once it is under production. Depending on production results, inner or outer coil modifications can be introduced to improve them.

Why is this such a good fit with inductors?

- No brazed joints and total design coil flexibility

- Total adaptation to the part to be heated

- Design continuous improvement

- High dimensional repeatability

- Assembled inductors cost is sometimes more economic due to the reduction of the labor needed.

Who uses your products?

Industrial manufactures from any sector using heating processes like heat treatment (hardening, tempering, …), brazing, welding, straightening, etc.

The GH 3D inductors are highly recommended to high volume productions as automotive industry and when complex parts need to be treated.

What is the goal of your business?

To be a reference in our induction heating sector and to become a global 3D inductor provider for any induction machine or system.

What kinds of companies would you be interested in working with?

With any that can clearly benefit from our technology and experience because upgrading the traditional inductors to 3D is more than printing. Experience in induction and in 3D coils is mandatory.

featured image: A 3D Printed Pure Copper Induction Coil; image credit: GH Group