EE Times published an interview with Murata president Norio Nakajima to understand his “Vision 2030” and the long-term plans of the company.

Murata Manufacturing is leveraging a digital twin and machine vision to improve manufacturing yield and component performance, particularly in MLCCs. Their Vision 2030 strategy focuses on standard products, application-specific components (ASCs), and new business models, with a growing emphasis on IT infrastructure and e-mobility.

Murata aims to differentiate itself through technical expertise, vertical integration, and strategic acquisitions, such as Resonant Inc., to develop cutting-edge solutions.

Improving manufacturing yield with a digital twin

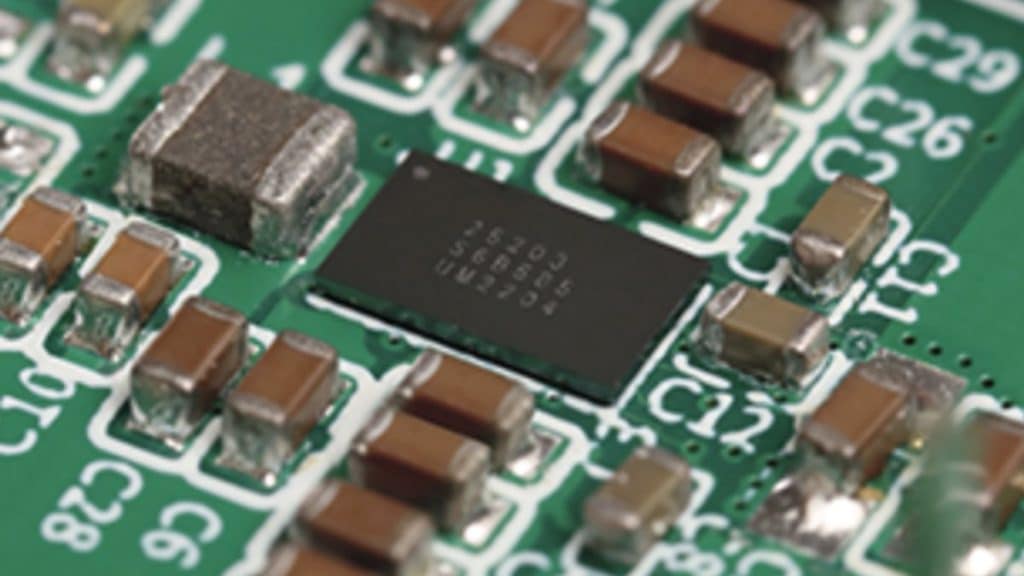

The recent global MLCC shortage highlighted the importance of reliable capacitor performance. Murata, a company with expertise in packaging, has expanded its product range to include wireless modules, MEMS sensors, power management solutions, and lithium-ion batteries. Nakajima discussed the use of a digital twin to enhance operations, noting that AI can classify production protocols based on failure types, aiding in the transition to automatic adjustments. Machine vision is used to label and classify surface deformities, providing feedback to control automated processes. Murata’s vertically integrated business model, where all materials and equipment are sourced internally, significantly impacts yield and component performance improvements.

Vision 2030: Passive components, end-solutions, and new business models

Murata has adopted Vision 2030, focusing on standard products, application-specific components (ASCs), and new business models. ASCs include packaged end solutions like wireless modules, Li-ion batteries, and sensor technologies. The company’s core businesses are communications and e-mobility, with a growing emphasis on IT infrastructure. Nakajima explained that Murata’s technical advantages, productivity improvements, and cost-oriented competition stem from its vertically integrated business model.

Competing on a global scale with ASCs

To differentiate itself, Murata acquired Resonant Inc., combining its filter manufacturing expertise with Resonant’s XBAR technology, which is suitable for higher frequencies and bandwidths. The company is also developing power solutions for automotive and data center applications, focusing on miniaturization and higher reliability components for IT infrastructure. Murata aims to enhance packaging solutions for high-powered applications in e-mobility and IT infrastructure.

Read the complete article here.