Source: Kemet Electronics, Phil Lessner Linked In blog

Magnetics has been around literally forever, but here at KEMET we’ve recently seen an upswing in demand for new and more advanced magnetic products and technologies. What’s driving this demand? The quick answer is the introduction of two fast-evolving technologies: electric and autonomous vehicles, and 5G communications.

KEMET makes two types of magnetics products for use in electrical applications. The first are magnetic components used in power applications; for instance, when an inductor is paired with a capacitor in a power conversion circuit. The second are the various filters and chokes used for electromagnetic interference (EMI) control and protection.

In terms of driving demand for new products that require advanced magnetics innovation, these two areas go hand in hand. As new markets and use cases are developed that use higher switching frequencies for power supplies, we are called on to develop new, capacitors and inductors to handle the higher frequencies. And since more EMI is emitted across a wider frequency range, new and more capable EMI filters and suppressors are also required.

An automobile is already a very noisy electronics environment, with a lot of components crammed into a relatively small space under the hood. But as you introduce even more electronics into electric cars, advanced driver assist system vehicles (ADAS), and fully autonomous vehicles, the EMI noise problem gets even more challenging.

As for 5G communication systems, they can bring with them very high frequencies, such as the millimeter-wave 5G near 28 gigahertz. These frequencies generate electromagnetic interference and require new components in order to attenuate the EMI they produce.

The dark arts of magnetics

Developing new and more advanced magnetic and EMI components has its challenges, and in fact is kind of a dark art.

A lot goes into the manufacturing of magnetics products: the density of the materials, the orientation of the plates, and the ability to change the material morphology and composition to make it more effective for particular electromagnetic frequencies. New magnetics components for automobiles may require custom geometries to fit under the hood with other automotive parts; we’re also asked to produce magnetic materials that will work dependably at higher and higher temperatures, and in harsh environments. We also do a lot of work to get the right shape for an EMI component or shield, adjusting the aspect ratio and size because the magnetic properties can depend on that.

To accommodate higher frequencies, we have made changes to material composition, and in some cases the shape of the particles affects the magnetic properties, and the way that magnetic materials interact with the environment. We’ve also developed specialized materials with unique compositions to deliver magnetic components that operate at higher currents with lower losses.

It’s quite complicated to get the materials right, and a lot of tuning goes on in terms of composition. We make most of our magnetic materials in-house, using formulas that we’ve developed over years of testing and R&D.

New magnetics products from KEMET

KEMET has introduced a number of new magnetics products recently, including NANOMET™️, the most advanced nanocrystalline material that is capable of a higher saturation current and lower power loss than traditional nanocrystalline materials. NANOMET™️ is designed for use in several different forms, including in KEMET’s new METCOM inductor product line. NANOMET™️ powder provides higher performing inductors than our standard metal powder material.

NANOMET™️ plate will also be used as a reactor in electric vehicles. Reactors can be used in circuits where battery voltage needs boosted from 300 volts to 450 or 500 volts. NANOMET™️ allows us to miniaturize this component, which is important in automotive applications because of limited space under the hood.

NANOMET™️ ribbon can also be made into metal sheets, like metal foil, that could be used in transformers instead of iron cores to provide higher efficiency and lower losses.

KEMET also has a new series of Flex Suppressor products that are suitable for 5G frequencies. Our new EFS series Flex Suppressor will meet the 10 to 40GHz high frequency range requirements for 5G, and it has already been incorporated into some optical transceiver modules and base station antennas.

FlakeComposite™️ is another new advanced magnetic material from KEMET. It’s based on the same micro-magnetic metal flakes used in our Flex Suppressor products but instead of suspending them in a flexible polymer material, we use a silicon dioxide binder to make a thin sheet that can be used for embedded inductors. The sheet of FlakeComposite™️ is so thin that it can be placed within a circuit board. This means that you can place an inductor beneath the rest of the components, instead of taking up space on the surface of the circuit board. This allows us to further miniaturize electronic devices.

KEMET has long been known for the wide variety of magnetics materials that we offer, and many OEMs value us as a trusted partner for development of custom magnetics products. This is supported not only by our expertise at material design but also by our sophisticated computer-aided design capabilities. This allows us to model custom capacitors or inductors in software and go through iterations more quickly than if we had to rely on physical prototyping alone.

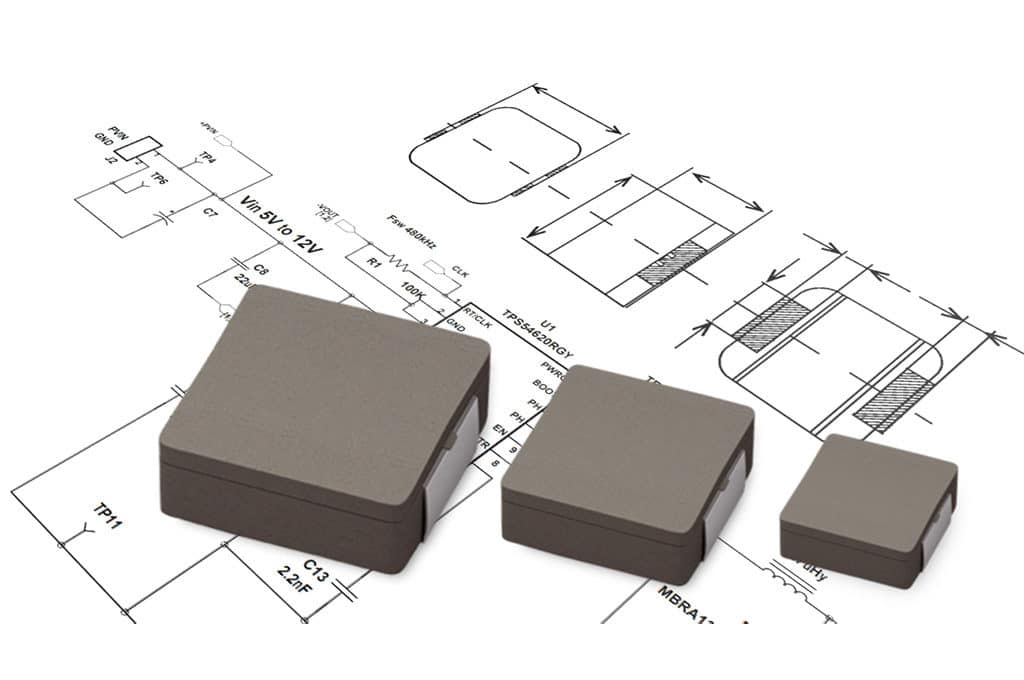

While KEMET is known for its custom magnetics products, the new METCOM series of metal composite power inductors incorporates our advanced magnetics materials in standard product lines available through our regular distribution channels. Our customers can still count on KEMET as a source for custom magnetic components, but they can now also take advantage of high-quality standardized magnetic components as well.