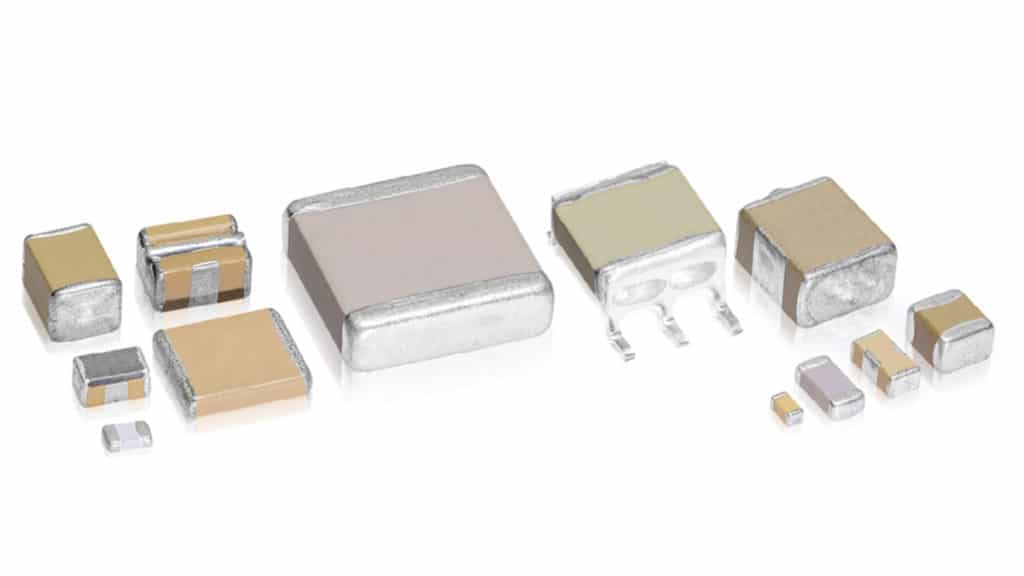

Knowles enhances Class I Ceramic C0G Series Capacitors to achieve twice the maximum capacitance, exceeding industry norms. With a maximum capacitance of 44nF/1kV and 66nF/630V in a compact chip size of 1210, the extended series is well suited to support LLC type DC/DC converters in demanding environments.

Knowles Corporation, a leading manufacturer of specialty electronic components, including high-performance capacitors, radio frequency (“RF”) filters, advanced medtech microphones, and balanced armature speakers, announced it is extending the range and performance of its Class I Ceramic C0G Series Capacitors to better support LLC type DC/DC converters.

Knowles’ unique construction allows these VM2 ceramic capacitors to offer higher capacitance values in a compact ceramic capacitor chip size.

The VM2 series of C0G ceramic capacitors includes:

- 500V: 39nF – 66nF

- 630V: 39n – 66nF

- 1kV: 27nF – 44nF

“This product range is designed with higher standards for performance and efficiency to align with next-generation electrification systems, including those using SiC-based converters,” said Jonathan So, Applications Engineer at Knowles.

“It’s an ideal fit for high-power density DC/DC converters in applications like EV onboard chargers, wireless charging systems, and potentially DC fast-charging infrastructure.”

Key Features & Advantages

- Extended Capabilities: Vertical Novel internal electrode design increases performance when handling ripple current.

- Compact Size: Chip size 1210 (3.2 x 2.5mm) can reduce component count and potentially replace a two-chip stack configuration.

- Wide Operating Temperature Range: Available in an AEC -Q2000-qualified, industrial-grade operating range of -55 degrees Celsius to 125 degrees Celsius.

- Best-in-Class ESR: Exceptional equivalent series resistance (ESR) ensures thermal stability in high-current, complex layouts.

This range extension is driven by the growing demand for higher power density and more volumetrically efficient converters in both EV and industrial markets. Knowles MLCCs support these goals by reducing losses and enhancing thermal performance in a small form factor.

See the full datasheet here: Surface Mount MLCC C0G Family Datasheet