Low ESR equivalent series resistance tantalum capacitors reduce voltage drop during discharge, and increase capacitor ripple current ratings thus improving both performance and efficiency of circuit designs.

The article written by Colin Li, field application engineer, KYOCERA AVX Components Corporation, explains some basic features and impacts of tantalum and low ESR tantalum capacitors.

Introduction

Tantalum is a relatively scarce transition metal with several unique properties that make it a technology-critical element. It is highly corrosion-resistant and chemically inert. It is non-ferrous and non-magnetic, has a high melting point and density, and is extremely stiff. Most importantly, Tantalum readily forms a protective and electrically insulating oxide layer. This ability makes it an ideal candidate as the base building block of electrolytic capacitors.

Such capacitors are constructed using a sintered pellet of powdered tantalum as the anode of the device (electrolytic capacitors are polarized.) This pellet is then submerged in an acid bath, and a voltage is applied across it. As a result, an oxide layer quickly forms on the contoured surface of the pellet, the thickness of which is proportional to the voltage applied.

Why Tantalum Capacitors?

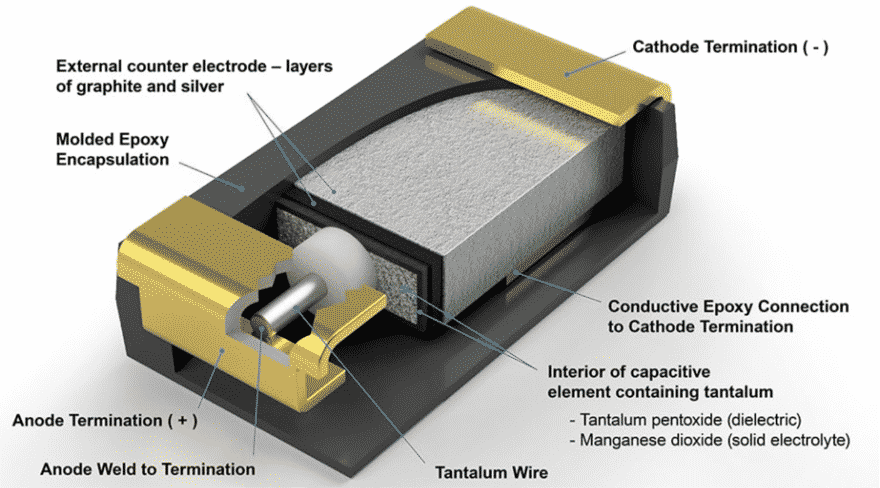

This oxide acts as the dielectric insulator in the final capacitor structure, and its large effective area and high breakdown voltage yield high reliability and high-density devices. The cathode terminal of the capacitor is then formed using either a solid or wet electrolyte to sufficiently contact the contours of the oxide layer. This electrolyte is interfaced using highly conductive materials such as graphite and silver and finally contacted and molded into a final part. The vast majority of tantalum electrolytics are packaged as surface-mounted devices, and an example cross section is shown in Figure 1.

Tantalum Capacitor Performance

The tantalum capacitor structure offers several key advantages when compared to other technologies. Tantalum capacitors are extremely dense (capacitance per unit volume) and can operate at relatively high voltages. They are also very reliable with self-healing properties and typically exhibit low electrical series resistance (ESR) and favorable AC impedance characteristics.

Figure 2 depicts the ESR and impedance curves of two typical tantalum capacitors. For these reasons, the two primary applications of tantalum capacitors in circuit design have been as high capacity energy storage elements and as ripple filtering components in power supplies.

Low ESR, High Ripple Current and High Energy Storage Capability

Solid tantalum capacitors are widely used to maintain voltage stability during peak current demand on a power rail. Two factors must be considered in this regard. The first is the total capacitance needed to provide the necessary energy. A single tantalum capacitor may be sufficient in some cases, but in more demanding applications, multiple capacitors must be configured in parallel.

The second factor is the ESR of the capacitor. Low ESR will reduce the voltage drop during discharge, thus improving both performance and efficiency. An example of this is the large capacitance required for a 3.3V power supply to power a microprocessor. During operation, the microprocessor may present a high current demand during a complex task.

The ability of a capacitor to effectively provide this high volume of energy is often referred to as the conversion rate, defined as the conversion of reactive current to peak current, expressed as a specific slope in A/μs. During peak demand, the rail voltage may need to be kept within a specified range (for example, a voltage drop less than 10% or 330 mV.) Low ESR tantalum capacitors can provide this higher discharge current while simultaneously reducing heat generation to meet these requirements quickly and more efficiently.

For short-term power draws, a designer could rely on several low-capacity multilayer ceramic capacitors (MLCC) as close as possible to the processor. MLCCs designed for ultra-low ESR can provide very high instantaneous current, but their limited capacity can only provide the required current for a short period. Large capacity capacitors (polymer tantalum capacitors, conventional tantalum capacitors, or aluminum electrolytic capacitors) are required for longer durations.

The use of lower ESR tantalum capacitors in this application can reduce the dependence of MLCC and reduce the quantity required, thus saving PCB board space and component cost. At the same time, they also help to improve plate-level reliability with a sturdier structure.

Power Supply Ripple Filtering

From the traditional full bridge rectifier shown in Figure 3 to modern switching converters, most power supplies exhibit noise on their output in the form of voltage ripple. It is often the job of a single or multi-stage output filter to eliminate this ripple and realize a smooth DC output voltage. This ripple is caused by variations of the input voltage supply, switching activity of the power supply itself, and variations in the output demand of the downstream load.

Tantalum capacitors are particularly well suited as energy storage elements in ripple filter circuits due to their low ESR. Since AC ripple is continuous and periodic, the capacitor ESR results in a continuous generation of heat as the current flows in and out of the capacitor. This is especially true in high-frequency switching supplies and high-speed processing loads where the ripple magnitude and frequency can be exceedingly high.

An example of a 250 kHz DC/DC output is shown in Figure 4, where a tantalum capacitor was used for output ripple filtering. The resulting waveform is much smoother with smaller spikes when compared to the original waveform. The low ESR, high-temperature stability, and low power dissipation factors make tantalum capacitors an excellent choice for such applications.

Tantalum Capacitors Selection Guide

Tantalum capacitor offerings can be divided into several different application spaces: high reliability, automotive, and high temperature. Within these spaces, capacitor variants include surface mount versus leaded termination and wet versus dry electrolytes. For high-reliability military, aerospace, and medical applications, KYOCERA AVX core qualifications are to the MIL-PRF-55365 standard. Smaller size, lower ESR, and multi-anode or multi-capacitor modules are all available in space level testing using the military T level and KYOCERA AVX’s SRC9000 specifications. These capacitors are also used extensively in the medical industry with the implantable grade HRC5000 and HRC6000 series.

For automotive applications, different requirements depend on their location within the vehicle with different operating requirements for temperature, voltage, and reliability level. Conventional tantalum / MnO2 capacitors offer a long lifetime, no wear-out mechanism, stable capacitance, and high operating temperature. Conductive polymer solid electrolytics feature very low ESR, benign failure mode, and high voltage ratings. Niobium Oxide (OxiCap®) capacitors are a unique subclass of electrolytics that provide extreme stability, a unique high resistance benign failure mode, and stable capacitance. Lastly, high-temperature MnO2 capacitors can meet automotive and industrial standards for high temperature (175°C operating), including AEC-Q200 qualification.

Bulk energy storage and power supply filtering require capacitors that are dense, reliable, and efficient. Tantalum capacitors hit all three of these targets and have become a staple in the electronics industry. From basic bypass capacitors in consumer electronics to high-reliability filter blocks in medical implants, tantalum capacitors have proven to be winners over many other capacitor technologies.