source: Murata news

Murata Manufacturing Co., Ltd. has introduced the GXT series of water repellent capacitors for automobile infotainment systems and comfort equipment. Designed with a water repellent layer on a multilayer ceramic capacitor, the product conforms to the AEC-Q200*1 electrical parts standard for automotive applications. This product is now in mass production.

Background

In conjunction with advances in size reduction and surface mount increased density in electronic equipment, there remains a possibility of generating a fault in circuit operation due to ion migration*2 in components by condensation in environments exposed to severe heat and humidity changes. For that reason, Murata has applied a water repellent layer to the surface of a multilayer ceramic capacitor that conforms to the AEC-Q200 automotive electronic components standards and thereby introduced a water repellent capacitor that can mitigate ion migration due to condensation.

Regarding water repellent capacitors, the company has offered the GXM series for general electronic equipment and the GGM series for automotive powertrain and safety applications, and is now adding the GXT series for automotive infotainment systems and comfort equipment.

Features

The structure of a water repellent capacitor is illustrated in Fig. 1. A water repellent layer has been applied to the surface of the capacitor. This water repellent condition of the capacitor maintains water droplets in a scattered state (Fig. 2), hindering growth of the condensed water drops that can connect the outside electrodes, and it thereby reduces the occurrence of ion migration. In addition, the water repellent film on the surface of the capacitor suppresses the elution of outside electrode metal to a water drop (ionization). In a wettability test using a water-soluble black marker (Fig. 4), the water repellent condition of a processed component is clearly superior to that of a component without the Murata Water repellent Layer. (Note: The goal of this Murata component is reduction of ion migration, not complete prevention of the effect.)

| |

||

| Fig. 1: Structural example of the water repellant capacitor | ||

| |

||

|

Fig. 2: Water repellant condition maintains

droplets in a scattered state.

|

Fig. 3: Suppression of metal

elution to water drop

|

|

| M+: Expresses state where a metal such as Sn or Cu has ionized. | ||

Fig. 4: Wettability test using a water-soluble black marker

(untreated components on left, water repellant processed components on right)

Applications

Examples: automotive infotainment systems, comfort equipment

(car navigation, audio equipment, etc.)

Electrical characteristics

| Temperature characteristics | X5R, X6S, X7R, X7S, C0G |

|---|---|

| Rated Voltage | 4~100Vdc |

| Capacitance tolerances | ±0.25pF, ±0.5pF, ±5%, ±10%, ±20% |

| Usage temperature range | -55~85°C (X5R), -55~105°C (X6S), -55~125°C (X7R, X7S, C0G) |

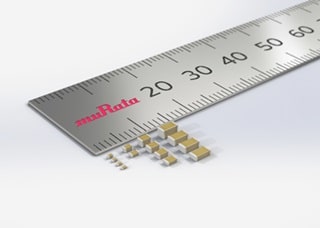

External size

LW size

0402 inch size: 1.0×0.5mm (T=0.5mm)

0603 inch size: 1.6×0.8mm (T=0.8mm)

0805 inch size: 2.0×1.25mm (T=1.25mm)

1206 inch size: 3.2×1.6mm (T=1.6mm)

1210 inch size: 3.2×2.5mm (T=2.0, 2.5mm)

Sample availability

Murata is accepting Web-based requests for free-of-charge samples for the following part numbers. Murata welcomes these sample requests.