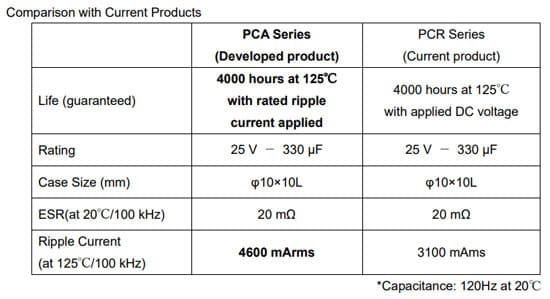

NICHICON CORPORATION has launched the PCA Series of chip-type conductive polymer aluminum solid electrolytic capacitors for use in automotive and industrial equipment environments requiring the high reliability. The PCA Series has the same ESR and other characteristics as the current PCR Series at 125℃, and has improved the ripple current, achieving industry-leading ripple current capability at 125℃.

Overview and Development Background

Previously, we have marketed our PCR Series of chip-type conductive polymer aluminum solid electrolytic capacitors in sectors demanding high reliability, such as automotive, industrial equipment, and telecommunications.

In recent years, the demand for the high maximum ripple current durability has been growing along with the use of electronic components in automobiles. To satisfy this demand, we launched the

PCA Series having a higher maximum ripple current than the PCR Series.

Features

The PCA series achieves high ripple tolerance while maintaining the same ESR performance and other characteristics as the current PCR series. This is made possible by improvements to our existing

technologies for heat resistance and ripple tolerance in conductive polymer aluminum solid electrolytic capacitors, and by further optimization of the conductive polymer formation method, component composition, and material design.

Further, the series offers the industry’s first conductive polymer aluminum solid electrolytic capacitors with rated voltages of 25–63V that are guaranteed with superimposed high ripple tolerance. The resultant higher ripple tolerance in capacitors of the same size contributes to more compact terminals by reducing the number of capacitors needed.

Key Specifications

- Rated voltage range : 25 to 63V

- Rated capacitance range : 47 to 470μF

- Category temperature range:-55 to 125℃

- Product dimensions :φ8×10L to φ10×12.7L(mm) (4 sizes)

- Life :4000 hours guaranteed at 125°C(Rated ripple current superimposed)

- Terminal shape :Chip type